Morgan Rushworth HSVS Hydraulic Variable Rake CNC Guillotine

| MODEL | STOCK CODE | CUTTING LENGTH | CUTTING CAPACITY (45 kg/mm2) | CUTTING CAPACITY (70 kg/mm2) | CUTTING ANGLE | STROKES PER MINUTE | No. OF HOLD DOWNS | WORKING PRESSURE | MAIN MOTOR | BACKGAUGE MOTOR | BACKGAUGE TRAVEL | OIL CAPACITY | No. OF SHEET SUPPORT ARMS | TABLE LENGTH | THROAT DEPTH | TABLE HEIGHT | TRANSPORT WIDTH | MACHINE WIDTH | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | mm | mm | deg | kg/cm2 | kw | kw | mm | lt | _A mm | _F mm | _G mm | _C mm | _C+E mm | _L mm | _C+D+E mm | _H mm | kg | |||||

| HSVS CNC 3100/6 | M1080 | 3070 | 6 | 4 | 0.5-1.5 | 10–32 | 16 | 260 | 11 | 0.37 | 1000 | 240 | 2 | 3450 | 350 | 800 | 1650 | 2700 | 3880 | 3190 | 2100 | 7800 |

| HSVS CNC 3100/10 | M1081 | 3070 | 10 | 6 | 0.5-2.0 | 12–18 | 15 | 260 | 22 | 0.37 | 1000 | 360 | 2 | 3480 | 350 | 800 | 1800 | 2850 | 3910 | 3300 | 2200 | 11000 |

| HSVS CNC 3100/13 | M1082 | 3070 | 13 | 8 | 0.5-2.5 | 9–14 | 15 | 260 | 30 | 0.37 | 1000 | 360 | 2 | 3520 | 350 | 800 | 1920 | 2970 | 3950 | 3385 | 2300 | 13000 |

| HSVS CNC 3100/16 | M1083 | 3070 | 16 | 10 | 0.5-3.0 | 8–14 | 15 | 260 | 30 | 0.55 | 1000 | 400 | 2 | 3540 | 350 | 900 | 1965 | 3015 | 3970 | 3380 | 2480 | 16500 |

| HSVS CNC 3100/20 | M1084 | 3070 | 20 | 13 | 0.5-3.0 | 6–10 | 16 | 260 | 37 | 0.55 | 1000 | 400 | 2 | 3580 | 350 | 1000 | 2350 | 3400 | 4010 | 3620 | 2700 | 21000 |

| HSVS CNC 3100/25 | M1085 | 3070 | 25 | 16 | 0.5-3.5 | 4–6 | 15 | 260 | 45 | 0.55 | 1000 | 600 | 2 | 3560 | 350 | 1100 | 2280 | 3330 | 3990 | 3605 | 3220 | 23000 |

| HSVS CNC 4100/6 | M1086 | 4070 | 6 | 4 | 0.5-1.5 | 16–25 | 21 | 260 | 11 | 0.55 | 1000 | 360 | 3 | 4460 | 350 | 900 | 2000 | 3050 | 4890 | 3450 | 2250 | 12000 |

| HSVS CNC 4100/10 | M1087 | 4070 | 10 | 6 | 0.5-2.0 | 9–14 | 21 | 260 | 22 | 0.55 | 1000 | 360 | 3 | 4500 | 350 | 900 | 1920 | 2970 | 4930 | 3380 | 2360 | 15000 |

| HSVS CNC 4100/13 | M1088 | 4070 | 13 | 8 | 0.5-2.5 | 7–14 | 21 | 260 | 30 | 0.55 | 1000 | 400 | 3 | 4520 | 350 | 1000 | 2280 | 3330 | 4950 | 3645 | 2630 | 18000 |

| HSVS CNC 4100/16 | M1089 | 4070 | 16 | 10 | 0.5-3.0 | 7–12 | 21 | 260 | 30 | 0.55 | 1000 | 400 | 3 | 4540 | 350 | 1000 | 2300 | 3350 | 4970 | 3630 | 2800 | 23500 |

| HSVS CNC 4100/20 | M1090 | 4070 | 20 | 13 | 0.5-3.0 | 6–9 | 21 | 260 | 37 | 0.55 | 1000 | 400 | 3 | 4570 | 350 | 1100 | 2350 | 3400 | 5000 | 3630 | 2900 | 26000 |

| HSVS CNC 6100/6 | M1091 | 6070 | 6 | 4 | 0.5-2.0 | 12–18 | 30 | 260 | 18.5 | 0.55 | 1000 | 360 | 4 | 6460 | 350 | 1000 | 2200 | 3250 | 6890 | 4130 | 2690 | 22000 |

| HSVS CNC 6100/10 | M1092 | 6070 | 10 | 6 | 0.5-2.0 | 6–10 | 30 | 260 | 22 | 0.55 | 1000 | 400 | 4 | 6480 | 350 | 1000 | 2200 | 3250 | 6910 | 4045 | 2750 | 30000 |

| HSVS CNC 6100/13 | M1093 | 6070 | 13 | 8 | 0.5-2.5 | 6–10 | 30 | 260 | 30 | 0.75 | 1000 | 400 | 4 | 6520 | 350 | 1200 | 2350 | 3400 | 6950 | 4200 | 3090 | 38000 |

| HSVS CNC 6100/16 | M1094 | 6070 | 16 | 10 | 0.5-3.0 | 5–9 | 30 | 260 | 37 | 0.75 | 1000 | 400 | 4 | 6540 | 350 | 1200 | 2500 | 3550 | 6970 | 4420 | 3250 | 43000 |

| HSVS CNC 6100/20 | M1095 | 6070 | 20 | 13 | 1.0-3.0 | 5–9 | 30 | 260 | 37 | 0.75 | 1000 | 600 | 4 | 6560 | 350 | 1200 | 2500 | 3550 | 6990 | 4280 | 3330 | 48000 |

Features

- Variable rake design

- CybTouch 12 Controller – CNC controlling blade gap, back gauge, stroke and cutting angle

- Adjustable stroke length to reduce stroke time when cutting narrower widths

- Digital stroke counter

- 1000mm powered ball screw backgauge with swing away feature for longer cutting lengths

- Back gauge retract feature

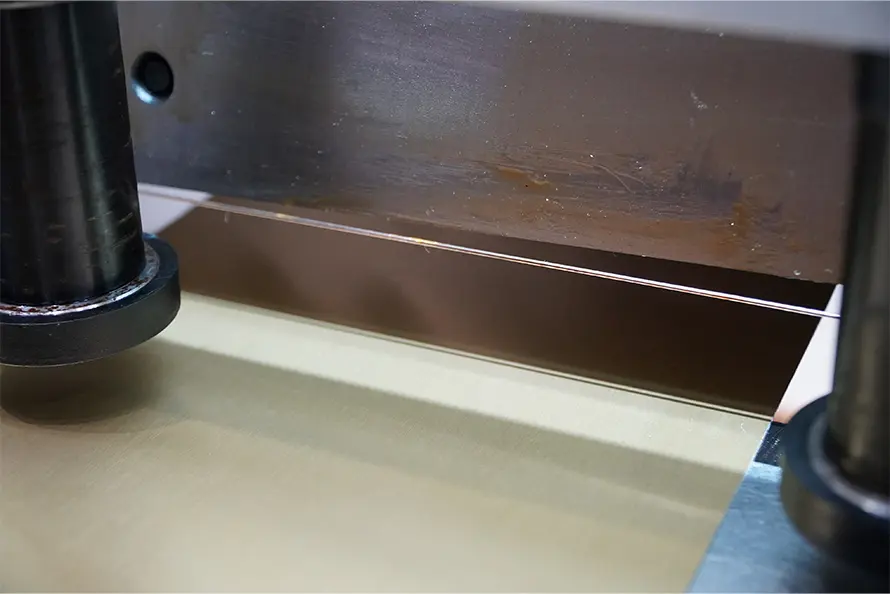

- High quality stainless grade top and bottom blades

- Top blade with 2 cutting edges and bottom blade with 4 cutting edges

- Cutting line illumination

- Front finger guards with windows

- Side throat guards

- Compact low-maintenance hydraulic system

- Hydraulic overload protection

- Powerful material hold downs to prevent sheet sliding during cutting action

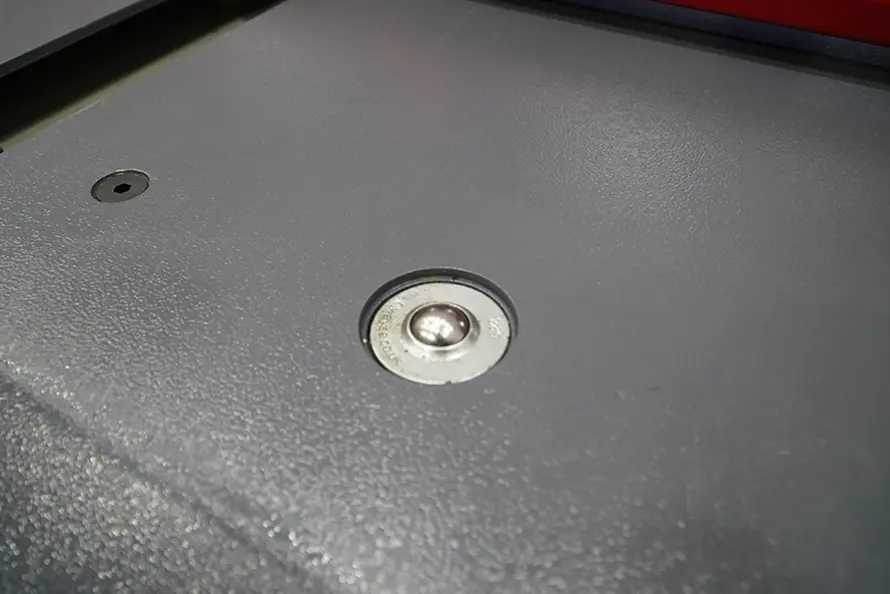

- Support table with roller bearings

- 1000mm Front squaring arm with measuring scale, tee slot and flip stop

- 1000mm Front support arms

- Foot pedal for single or continuous cutting cycles

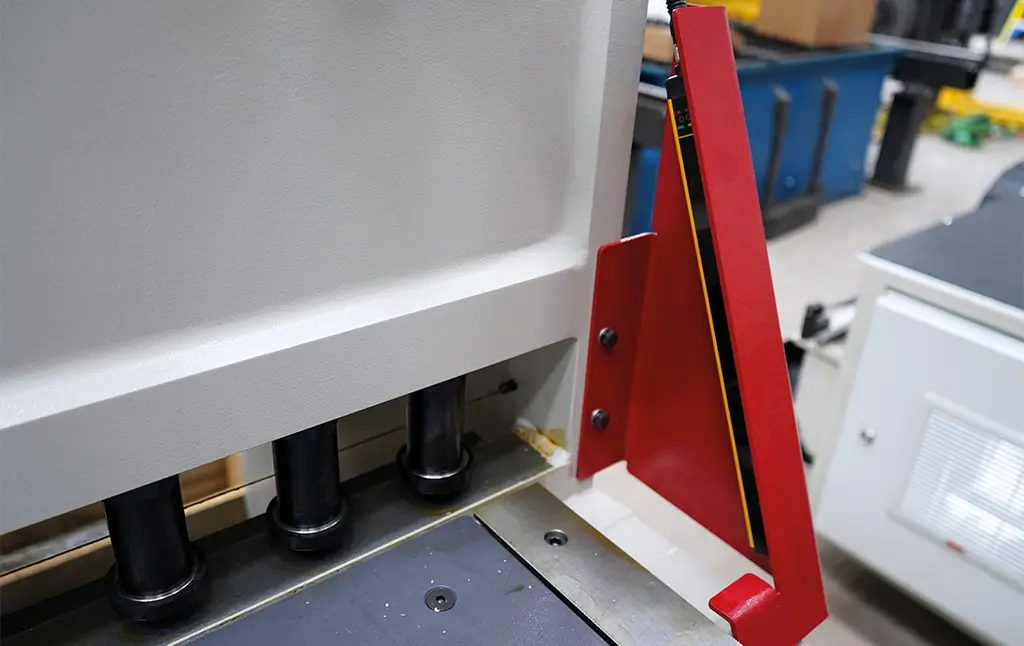

- Photo cell rear guards

- Centralised lubrication system

Options

- Pneumatic rear sheet support system

- Anti twist device

- Hydraulic automatic swing away back gauge in lieu of standard powered

- Angle gauge

- Tee slots and flip stops on front support arms

- 1 metre lift up finger guard with interlock switch

- Front CE light guards in lieu of standard fixed front guards

Morgan Rushworth HSVS Variable Rake CNC Guillotines: Precision and Performance Redefined

The Morgan Rushworth HSVS range of variable rake CNC guillotines is engineered for performance, reliability, and precision. Designed to meet the demands of production environments, these heavy-duty machines combine robust construction with advanced CNC technology to deliver exceptional cutting results. Whether working with thick or thin materials, the HSVS guillotines handle a wide range of applications while maintaining consistent quality and efficiency.

Intelligent CNC Controller for Optimised Efficiency

A standout feature of the HSVS guillotines is the intelligent CNC controller, which simplifies operation by automating critical adjustments. Operators can easily input cutting parameters, and the machine adjusts the blade gap, back gauge position, cutting angle, and stroke length automatically. This advanced automation increases strokes per minute, reduces cutting times, and ensures optimal performance for every cut. For manufacturers focused on maximising throughput, this combination of speed and precision is a game-changer.

Variable Rake Capability for Superior Cuts

The variable rake functionality distinguishes the HSVS range from standard guillotines. By dynamically adjusting the cutting angle to match material thickness, these machines minimise sheet twisting and warping. This results in cleaner cuts and uniform finished parts, reducing rework and waste. The ability to handle different materials and thicknesses with precision makes the HSVS guillotines both cost-effective and environmentally friendly.

Durability and Longevity for Continuous Operation

Durability is a core principle of the Morgan Rushworth HSVS guillotines. Constructed with high-quality materials and a stable frame, these machines are built to withstand the demands of continuous production. The robust components ensure reliable performance over years of use, with minimal maintenance required. This durability minimises downtime, providing businesses with consistent output and ensuring timely delivery of products.

User-Friendly Operation for Enhanced Productivity

The CNC interface of the HSVS guillotines is intuitive and easy to navigate, enabling operators to quickly utilise the full capabilities of the machine. The straightforward controls reduce the learning curve for new staff and improve overall productivity. Combined with the machine’s advanced automation, even complex cutting tasks are completed with ease and precision, streamlining workflows and boosting efficiency.

Safety Features for Operator Protection

Safety is a top priority in the design of the HSVS range. Each machine is equipped with protective features, including emergency stop buttons and strategically placed guards, ensuring a safe working environment. Operators can work with confidence, knowing that the machine complies with workplace safety regulations while still providing clear visibility of the cutting area for accurate operation.

Flexibility for Diverse Applications

The HSVS guillotines are versatile machines capable of handling a wide variety of materials and thicknesses. From cutting large, thick sheets to working with finer materials, these machines deliver consistent, high-quality results. This flexibility allows businesses to take on a broader range of projects, making the HSVS range a valuable asset for workshops and manufacturing facilities.

Optional Features and Customisation

To meet specific production needs, the HSVS guillotines offer a range of optional features and upgrades, including:

- Additional back gauge configurations.

- Extended cutting lengths.

- Enhanced control systems for increased precision.

These customisation options ensure the machines can adapt to evolving requirements, providing a future-proof investment that grows with the business.

Summary: Advanced Cutting Solutions for Modern Manufacturing

The Morgan Rushworth HSVS variable rake CNC guillotine range combines advanced technology, robust construction, and user-friendly operation to deliver outstanding cutting solutions. With features such as the intelligent CNC controller, variable rake functionality, and heavy-duty design, these machines are an ideal choice for high-volume production environments where precision and reliability are essential.

By reducing material waste, improving productivity, and offering long-term durability, the HSVS guillotines provide businesses with a superior cutting solution that enhances both quality and efficiency. For those seeking to optimise their metal cutting capabilities, the HSVS range stands out as a reliable and versatile choice.