Morgan Rushworth HSGS NC Swing Beam Guillotine 415V

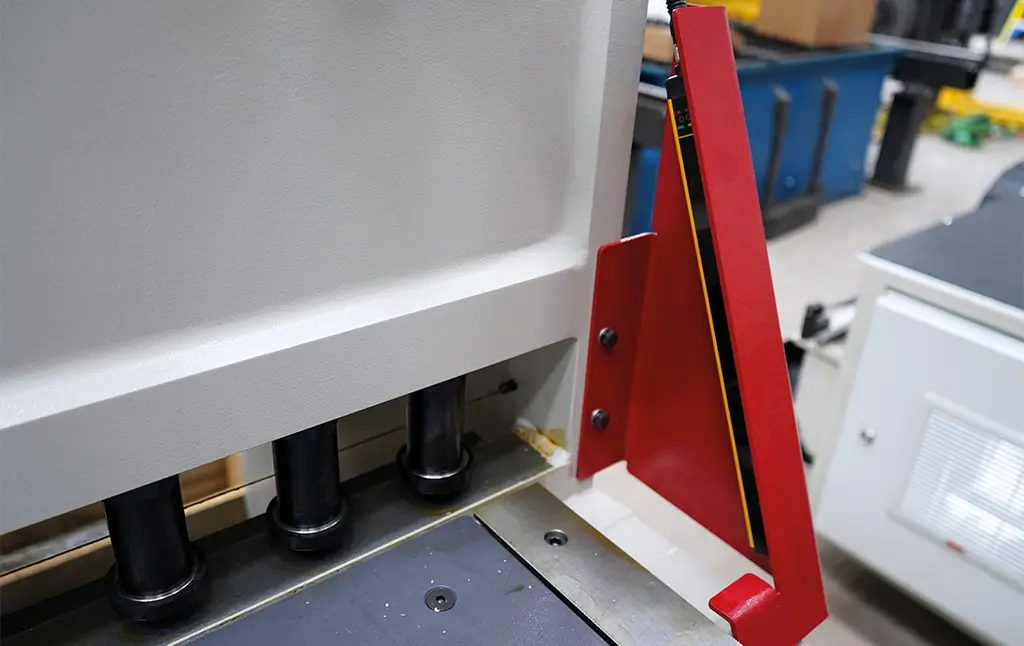

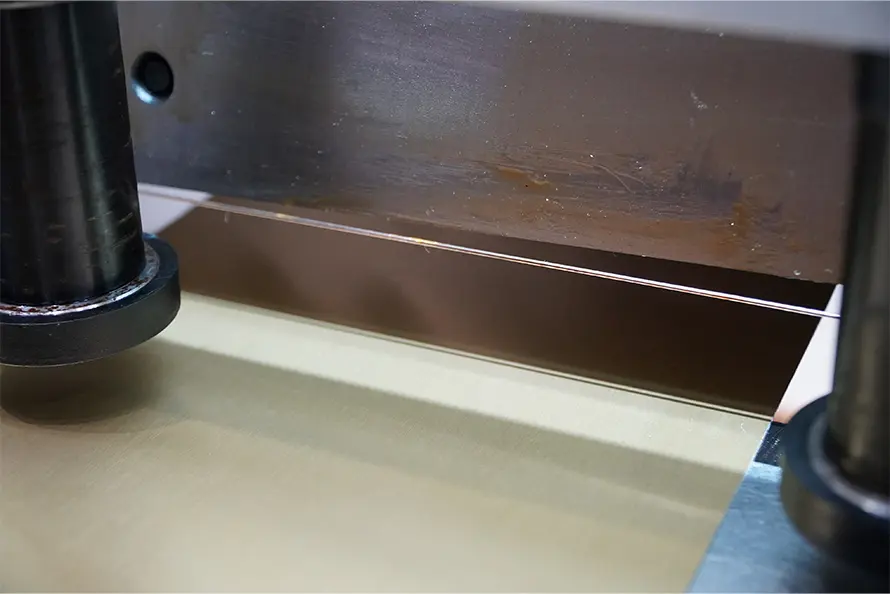

The Morgan Rushworth HSGS hydraulic swing beam guillotines now offer an advanced optional front light guard. This innovative system uses multiple beams across the blade and hold-down area, shutting the machine off instantly if interrupted. By eliminating the need for a traditional guard, it enhances operator safety while providing a clearer view of the workpiece.

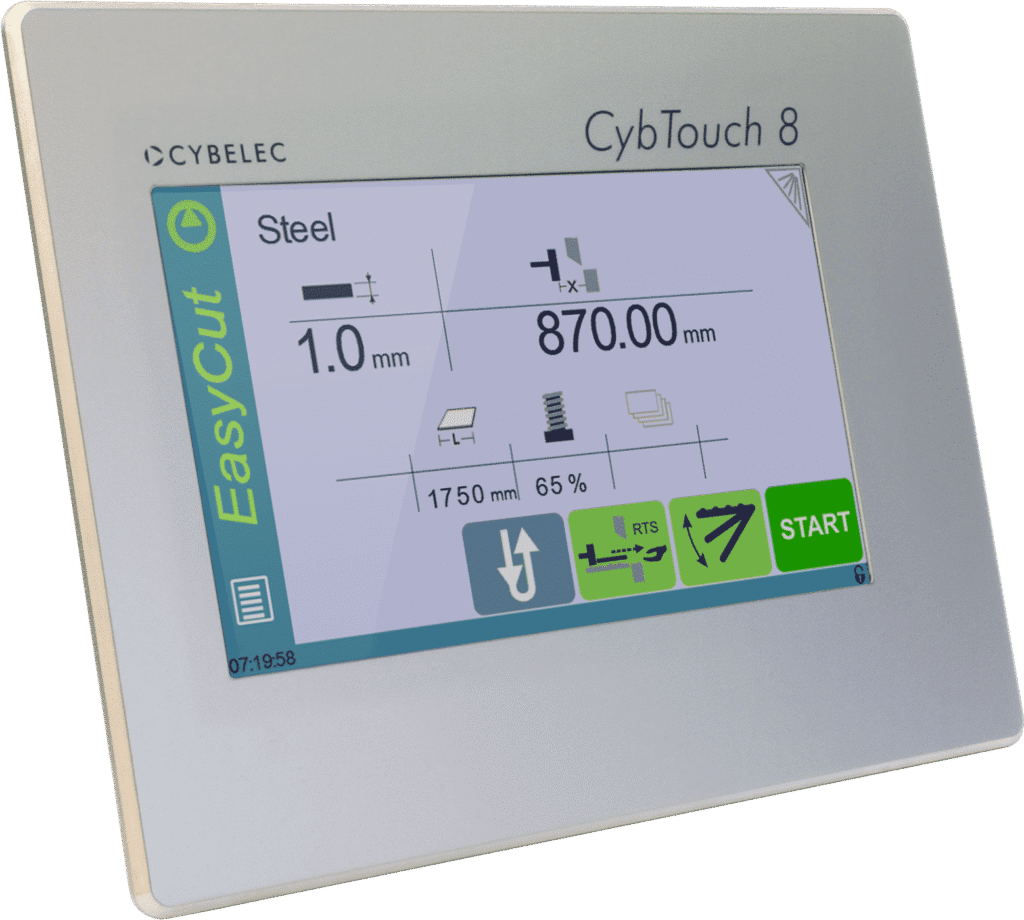

The HSGS range comes equipped with durable stainless steel cutting blades as standard, ensuring reliable performance and longevity. The NC controller allows for precise cutting and efficient production, enabling the programming of complete cutting lists.

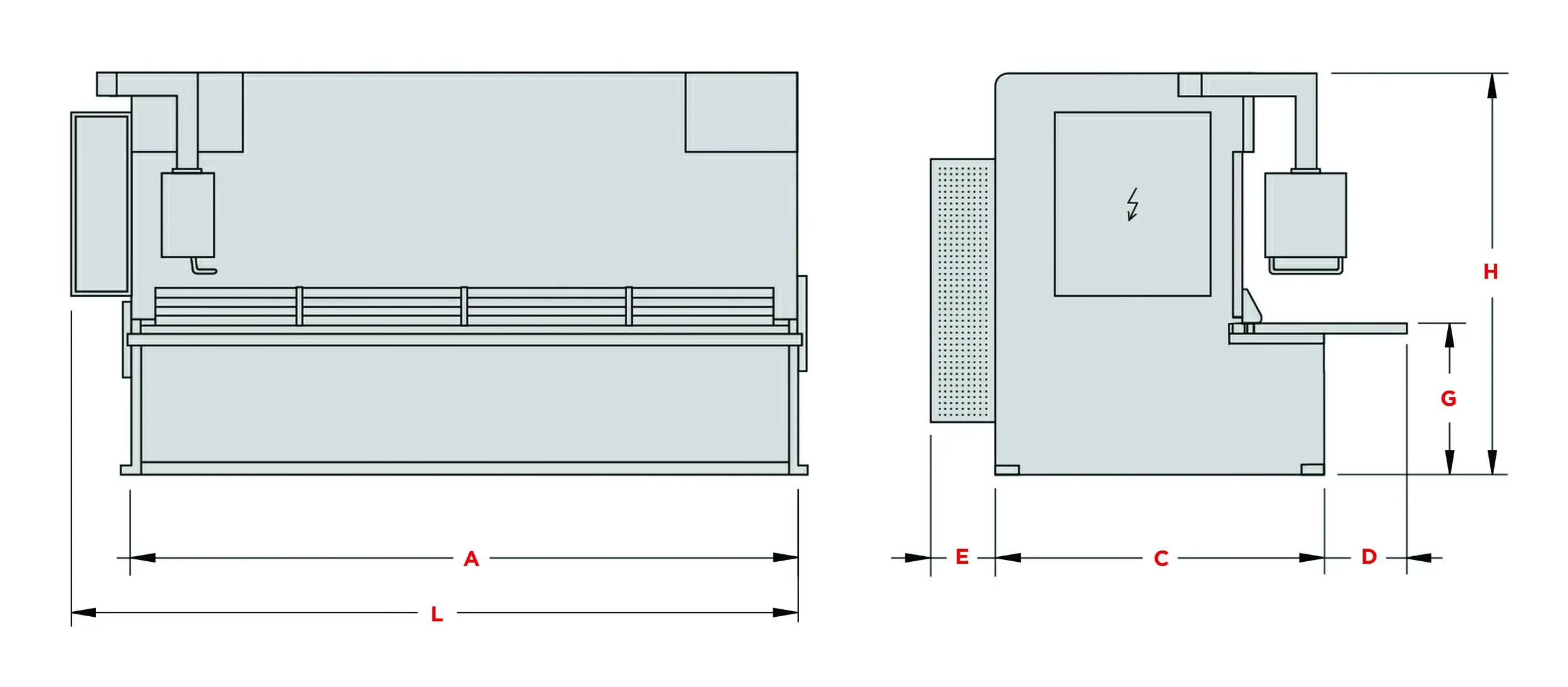

| MODEL | STOCK CODE | CUTTING LENGTH | CUTTING CAPACITY (45 kg/mm2) | CUTTING CAPACITY (70 kg/mm2) | CUTTING ANGLE | STROKES PER MINUTE | No. OF HOLD DOWNS | MAIN MOTOR | BACKGAUGE MOTOR | BACKGAUGE TRAVEL | OIL CAPACITY | TABLE LENGTH | TABLE HEIGHT | TRANSPORT WIDTH | MACHINE WIDTH | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | kw | kw | mm | lt | _A mm | _G mm | _C mm | _C+E mm | _L mm | _C+D+E mm | _H mm | kg | |||||||

| HSGS 2600/6 NC | M1057 | 2560 | 6 | 4 | 1.6 | 24 | 15 | 12.5 | 0.37 | 750 | 160 | 2760 | 800 | 1260 | 2460 | 3190 | 2940 | 1570 | 4670 |

| HSGS 3100/6 NC | M1058 | 3060 | 6 | 4 | 1.6 | 20 | 17 | 12.5 | 0.37 | 750 | 160 | 3260 | 800 | 1320 | 2520 | 3690 | 3000 | 1570 | 5450 |

| HSGS 3100/8 NC | M1059 | 3060 | 8 | 5 | 1.8 | 13 | 17 | 16.5 | 0.37 | 750 | 160 | 3305 | 800 | 1450 | 2650 | 3735 | 3130 | 1650 | 6380 |

| HSGS 3700/6 NC | M1060 | 3660 | 6 | 4 | 1.2 | 18 | 20 | 12.5 | 0.37 | 750 | 160 | 3965 | 800 | 1450 | 2650 | 4395 | 3130 | 1650 | 7300 |

| HSGS 4100/6 NC | M1061 | 4060 | 6 | 4 | 1.2 | 12 | 23 | 12.5 | 0.37 | 750 | 160 | 4305 | 900 | 1560 | 2760 | 4735 | 3190 | 1750 | 9150 |

| HSGS 2100/6 NC | M1056 | 2100 | 6 | 4 | 1.6 | 24 | 15 | 11 | 0.37 | 750 | 160 | 2260 | 800 | 1990 | 2440 | 2790 | 2460 | 1570 | 4400 |

Features

- NC Controller for back gauge position.

- One-piece honed and chrome plated double acting powerful cylinders.

- Stainless steel cutting blades. Bottom: 4, Top: 2 cutting sides.

- Easy adjustable blade gap adjustment system from single point.

- Bosch – Rexroth hydraulic system.

- High pressurized silent Atos pump.

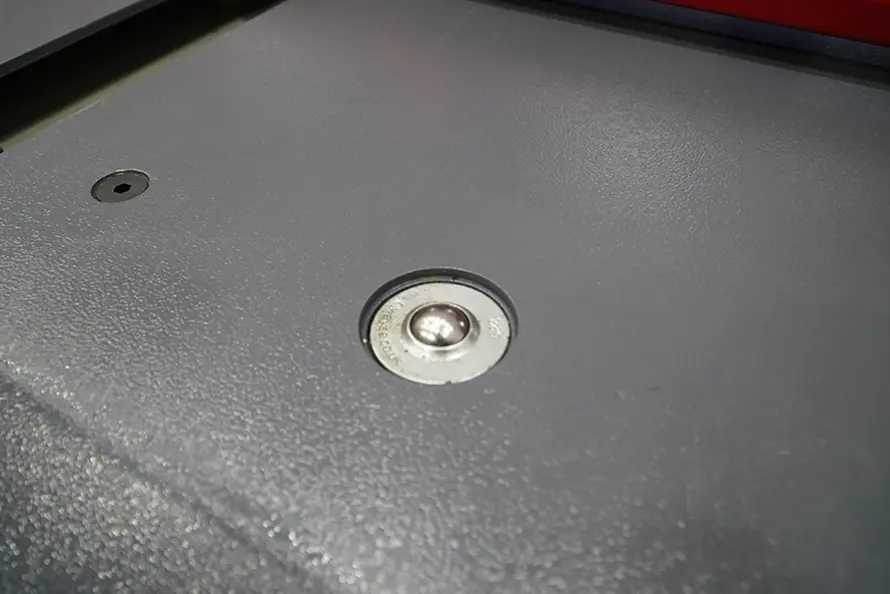

- Fast and powerful back gauge with 750mm distance, moving by ball screwed shafts, with automatic swing away feature.

- Powerful hydraulic material hold downs.

- Cutting length adjustment allowing stroke adjustment for shorter sheets and shorten the cutting time.

- Support table with roller bearings.

- Front support arms with ruler and flip stop.

- Foot pedal available for single or continuous cutting.

- Cutting line illumination.

- Rear guard with photo-cell

Options

- Delem DAC 310 controller.

- Delem DAC 310 controller with powered blade gap adjustment.

- Front light finger guard system

- Pneumatic sheet supports

- Angle Gauge.

- Longer Squaring arm and support arms.

- 1000mm back gauge

Morgan Rushworth HSGS Hydraulic Swing Beam Guillotines: Precision and Safety Redefined

The Morgan Rushworth HSGS range of hydraulic swing beam guillotines is engineered to deliver exceptional performance, safety, and precision in modern metalworking environments. Renowned for high-quality engineering and advanced features, the HSGS range is a reliable solution for workshops, factories, and production facilities that demand accuracy and efficiency.

Advanced Front Light Guard System for Enhanced Safety

A standout innovation in the HSGS range is the optional advanced front light guard system, which represents a significant leap forward in operator protection and usability. This safety feature projects multiple light beams across the front of the blade and hold-downs. If any beam is interrupted, the machine shuts off immediately, ensuring operator safety. Replacing traditional physical guards, this system not only enhances safety but also offers a clearer view of the workpiece, enabling precise control during cutting. The result is a safer, more ergonomic workspace with improved visibility and ease of operation.

Stainless Steel Blades for Durability

The HSGS range comes equipped with stainless steel cutting blades as standard, ensuring long-lasting performance. These blades are resistant to corrosion and wear, maintaining their sharpness even after extended use. This durability reduces the frequency of blade replacements, saving time and lowering maintenance costs. With consistent cutting performance, the HSGS guillotines are an economical choice for workshops and production facilities.

Advanced NC Controller for Precision Cutting

The inclusion of an advanced NC (numerical control) controller allows operators to achieve precise and repeatable cuts. The NC controller enables adjustments to cutting dimensions and supports the creation of cutting lists with specific quantities. By programming these lists in advance, operators can streamline production, minimise material waste, and ensure consistent results. This feature is particularly valuable in high-volume environments, where efficiency and quality are critical.

Hydraulic Swing Beam Design for Improved Performance

The hydraulic swing beam design of the HSGS guillotines enhances both performance and reliability. Unlike mechanical systems, hydraulic systems deliver smoother and more consistent cutting action. The swing beam evenly distributes cutting forces, resulting in clean, burr-free edges and longer blade life. This design also reduces vibration during operation, improving cut quality, operator comfort, and machine stability.

Ergonomic and User-Friendly Operation

The HSGS guillotines are designed with ergonomics in mind, offering an intuitive control layout and enhanced visibility through the advanced light guard system. This user-centric approach ensures operators can maintain precision and focus, reducing downtime and increasing productivity. The machine’s design makes it easy for both new and experienced operators to quickly become proficient, enabling seamless integration into any workflow.

Optional Accessories for Flexibility

To meet diverse production needs, the HSGS range offers a variety of optional accessories and upgrades, including:

- Extended sheet supports for larger materials.

- Additional back gauges for improved precision.

- Programmable cutting sequences for recurring tasks.

These options allow businesses to tailor the HSGS guillotines to specific metalworking requirements, enhancing versatility and productivity.

Comprehensive Safety Features

Safety is prioritised throughout the design of the HSGS range. In addition to the front light guard system, the machines feature emergency stop buttons and protective barriers, ensuring compliance with industry regulations and operator peace of mind. These measures make the HSGS guillotines a safe and reliable choice for modern workshops.

Durability and Long-Term Reliability

Built from heavy-duty materials and equipped with high-quality components, the HSGS guillotines are designed to withstand the demands of daily production. The robust hydraulic system, stainless steel blades, and swing beam construction work together to provide consistent performance and minimise maintenance costs. This durability ensures that the HSGS range remains a sound investment for businesses seeking to enhance their cutting capabilities.

Why Choose the HSGS Guillotine Range?

The Morgan Rushworth HSGS range offers:

- Exceptional Safety: Advanced light guards and emergency stops for operator protection.

- Precision Cutting: Stainless steel blades and NC controllers for consistent results.

- Enhanced Performance: Hydraulic swing beam design for clean, burr-free cuts.

- Flexibility: Optional upgrades to suit specific production needs.

- Durability: Built to last in demanding industrial environments.

Conclusion

The Morgan Rushworth HSGS hydraulic swing beam guillotines set a new standard in precision cutting technology. Combining advanced safety features, durable stainless steel blades, an intuitive NC controller, and a robust hydraulic design, this range delivers unmatched performance and efficiency. Whether for small workshops or large-scale production facilities, the HSGS guillotines provide the flexibility, accuracy, and reliability required to meet the demands of modern metalworking industries.