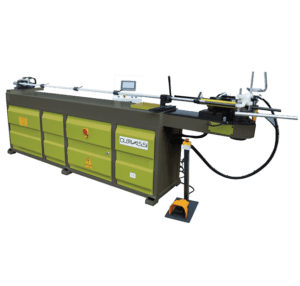

Curvassi MTX 32 / MTX 32H Bow Top Fencing Bending Machine

The Curvassi MTX32 / MTX32H Bow Top Fencing Bending Machine is an entry-level mandrel tube bender designed for fast and precise 180° bending. With the option of a manual or hydraulic vice, it delivers efficiency and ease of use, particularly in production environments. Specialist tooling enables the bending of hollow tubes or solid round and square bars, ideal for creating bow tops. The machine can bend three 12mm solid bars simultaneously, completing each sequence in just four seconds.

Tooling options allow for bending solid round or square bars up to 18mm, making it a versatile choice for fencing production.

| MODEL | MTX 32 (Manual Vice) | MTX 32H (Hydraulic Vice) | |

| Max Pipe Diameter | mm | 32 | 32 |

| Max Wall Thickness | mm | 2 | 2 |

| Max Solid Bar Diameter | mm | 18 | 18 |

| Max Bow-Top Capacity | 3no of 12mm Bar | 3no of 12mm Bar | |

| Max Bending Radius | mm | 300 | 275 |

| Max Bending Angle | (°) | 190 | 190 |

| Bending Speed | (0/sn) | 68 | 60 |

| Vice Operation | Manual | Hydraulic | |

| Motor | kw | 2.2 | 2.2 |

| Weight | kg | 280 | 400 |

| Length | mm | 1950 | 1950 |

| Width | mm | 850 | 1000 |

| Height | mm | 950 | 1050 |

Features

- Built according to EC Safety Directives (CE-Mark Approved)

- Heavy Duty Construction

- Excellent bend quality

- Very Easy To Use

- Geared Motor Drive

- Foot Pedal Control

- Manual (MTX32) / Hydraulic Clamping Movement (MTX32H)

- Electrical Parts – Simens/Telemecanique

- Complete tooling service

Options

- Manual Flip Length Stop System

- Hydraulic Vice on MTX32H

- Tooling for Hollow Tube / Solid Round or Square Bar

Bringing Manufacturing In-House: The Benefits and Challenges

At Selmach, we’ve seen a growing trend of businesses taking control of their manufacturing processes by bringing previously outsourced tasks in-house. Many customers who used to purchase the bow top components of railings are now exploring ways to fabricate these parts themselves. Supply chain challenges, rising costs, and the desire for greater control over production have driven this shift.

By taking on the entire process internally, companies can achieve significant cost savings on materials, reduce dependency on third-party suppliers, and streamline their operations. Producing bow top components in-house also eliminates the need to store pre-purchased components, providing greater flexibility for meeting customer demands.

The Bow Top Manufacturing Process

The process of producing bow tops is straightforward: it involves bending tubular steel at a 180-degree angle repeatedly. While simple in theory, the challenge lies in finding the most efficient and cost-effective method to achieve precise, consistent bends.

Introducing the Curvassi MTX32 Bow Top Fencing Bending Machine

The Curvassi MTX32 is an entry-level mandrel tube bender specifically designed for fast, accurate, and repeatable 180-degree bends. This machine is perfect for businesses looking to bring bow top production in-house without compromising on efficiency or precision.

Available in two configurations, the MTX32 allows you to choose between:

- Manual Vice: A cost-effective option, offering flexibility and simple operation.

- Hydraulic Vice: An upgraded version with enhanced efficiency and ease of use, operated via foot pedal controls for hands-free operation.

Both options ensure consistent results, making the MTX32 suitable for small workshops and high-production environments alike.

Fast and Efficient Production

One of the key features of the Curvassi MTX32 is its speed. With the ability to complete a 180-degree bend in just four seconds, it is ideal for production environments where time is critical. The machine can bend up to three 12mm solid bars simultaneously, significantly increasing output compared to manual methods.

Additionally, the hydraulic vice option offers an automatic mode, further improving productivity by minimising operator intervention. This makes the MTX32 a highly efficient solution for high-volume manufacturing.

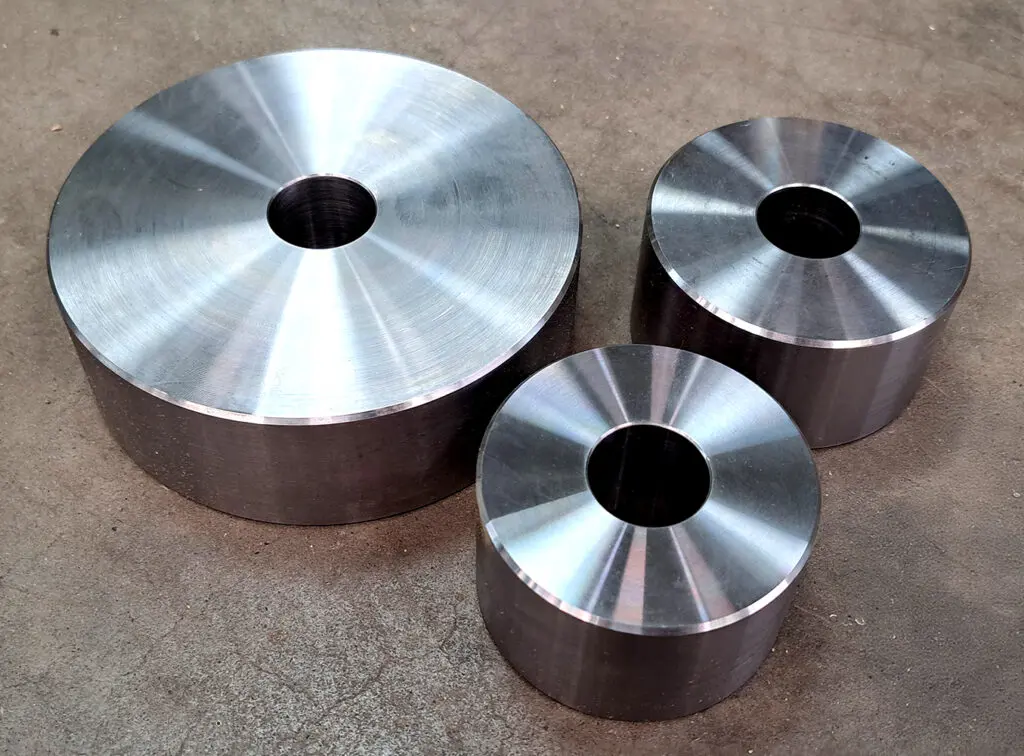

Tooling Options for Versatility

The Curvassi MTX32 comes with a range of specialised tooling options, enabling businesses to work with various materials and dimensions. With the appropriate tooling, you can bend:

- Hollow Tubes: Perfect for lightweight applications.

- Solid Round Bars: Up to 18mm in diameter, ideal for robust fencing designs.

- Square Bars: Up to 18mm in size, offering more design possibilities.

This versatility ensures the MTX32 can meet the demands of a wide range of customers and applications, from standard bow tops to custom railing designs.

Suitability for Production Environments

The Curvassi MTX32 is particularly well-suited for production environments, where speed, consistency, and reliability are paramount. Its compact design allows it to fit seamlessly into workshops of any size, while its robust construction ensures long-term durability.

The flexibility of choosing between manual and hydraulic vices makes the machine adaptable to different production needs. For smaller operations, the manual vice offers precise control and simplicity, while larger facilities can benefit from the efficiency of the hydraulic vice.

Cost-Effective Investment

The cost of the Curvassi MTX32 ranges from £7,000 to £12,000 + VAT, depending on the configuration and tooling options chosen. While this may seem like a significant investment, the machine quickly pays for itself by enabling businesses to produce bow tops in-house.

Bringing production in-house eliminates the ongoing costs of purchasing pre-made components and reduces dependency on external suppliers. Additionally, businesses can respond more flexibly to customer demands, produce custom designs, and avoid delays caused by supply chain issues.

Manual vs Hydraulic Vice: Choosing the Right Option

The choice between a manual and hydraulic vice depends on the specific needs of your business:

- Manual Vice:

- Ideal for smaller workshops or lower production volumes.

- Allows operators to open and close the vice manually, offering precise control over the bending process.

- Hydraulic Vice:

- Perfect for high-production environments where efficiency is a priority.

- Operated via foot pedal controls, offering hands-free operation and greater ease of use.

Both options ensure consistent bending quality, allowing businesses to choose the configuration that best suits their workflow and budget.

Why Choose the Curvassi MTX32?

The Curvassi MTX32 offers an affordable, efficient, and versatile solution for businesses looking to bring bow top railing production in-house. Its ability to bend tubular steel, solid round bars, and square bars with speed and precision ensures it meets the needs of a wide range of applications.

By investing in the MTX32, businesses can:

- Save money on materials by eliminating the need to purchase pre-made components.

- Reduce dependence on third-party suppliers, ensuring greater control over production.

- Increase efficiency with fast bending cycles and minimal downtime.

- Adapt to customer demands with versatile tooling options.

Final Thoughts

As businesses face rising costs and supply chain challenges, taking control of manufacturing processes is becoming increasingly important. The Curvassi MTX32 Bow Top Fencing Bending Machine provides an excellent opportunity to bring bow top production in-house, offering a reliable and cost-effective solution.

With its fast bending cycles, versatile tooling, and the option of manual or hydraulic operation, the MTX32 is the perfect choice for fabricators and manufacturers looking to enhance their capabilities. For an investment starting at £7,000 + VAT, this machine can revolutionise your production process and deliver long-term savings.