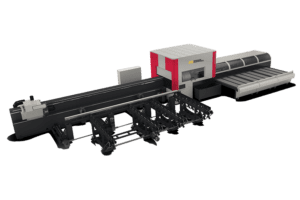

Mueller Opladen 3D Pipe Profiling Machines

Müller Opladen Gmbh have been manufacturing tube and pipe profiling machines since the 1950s. Over the years they have developed machines that offer 3D cutting of pipes and tubes, covering pipe diameters from 50 to 4064 mm ( 2” to 160”).

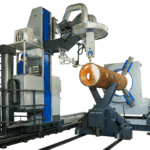

The pipe profiling and vessel profiling models have a minimum of 6 CNC axes, where 4 axis are required for cutting and the 5th and 6th axis are used for adapting to deviations in the outer pipe diameter. With CAD-CAM integration software CAD files can be uploaded from the office and sent to the machine for profile cutting. Their 3D cutting processes are oxyfuel cutting or plasma cutting and they work with Hypertherm and Kjellberg for their conventional and high definition plasma systems.

Before cutting the machine is probing the pipe to understand where the deviations are that the CNC system has to adapt on during the cutting process. With this technology the 3D pipe profiling machines provide a perfect smooth 3D profile cut on bevels, slots, saddles, mitre cuts and many more profile cut shapes.

This product is now discontinued however we'd be happy to discuss alternative options with you. If you're looking for consumables, servicing or spare parts for this product, please contact our sales team.

VIEW AlTERNATIVES

| MODEL | MO-Compact 400 | MO-Compact 600 | MO-Compact 800 | MO-Compact 900 | MO-Classic 600 | MO-Classic 1200 | MO-Classic 1500 | MO-Classic 2000 | MO-Heavy Duty 2000 | MO-Heavy Duty 2500 | MO-Heavy Duty 3000 | MO-Heavy Duty 4000 | |

| Pipe Diameter Range | mm | 50 – 406 | 50 – 610 | 50 – 812 | 50 – 914 | 50 – 610 | 50 – 1220 | 80 – 1524 | 80 – 2032 | 200 – 2032 | 200 – 2540 | 200 – 3048 | 200 – 4064 |

| Square/Rectangular Pipe Size Range (Optional) | mm | N/A | N/A | N/A | N/A | 100×100 – 240×240 | 100×100 – 420×420 | 100×100 – 640×640 | 100×100 – 640×640 | N/A | N/A | N/A | N/A |

| Pipe Length Range | mm | 300 – 12,000 | 300 -12,000 | 300 – 12,000 | 300 – 12,000 | 300 – 24,000 | 300 – 24,000 | 300 – 24,000 | 300 – 24,000 | 300 – 24,000 | 300 – 24,000 | 300 – 24,000 | 300 – 24,000 |

| Maximum Workpiece Weight | kg | 4,000 | 4,000 | 4,000 | 4,000 | 12,000 | 12,000 | 12,000 | 12,000 | 40,000 | 40,000 | 40,000 | 40,000 |

| Wall Thickness Range (Oxy-Fuel) | mm | 5 – 60 | 5 – 60 | 5 – 60 | 5 – 60 | 5 – 150 | 5 – 150 | 5 – 150 | 5 – 60 | 5 – 180 | 5 – 180 | 5 – 180 | 5 – 180 |

| Wall Thickness Range (Plasma) | mm | 5 -35 | 5 – 35 | 5 – 35 | 5 – 35 | 1 – 80 | 1 – 80 | 1 – 80 | 1 – 80 | 1 – 80 | 1 – 80 | 1 – 80 | 1 – 80 |

| Torch Angle Range | Deg | ± 60 / 45 | ± 60 / 45 | ± 60 / 45 | ± 60 / 45 | ± 70 / 45 | ± 70 / 45 | ± 70 / 45 | ± 70 / 45 | ± 70 / 45 | ± 70 / 45 | ± 70 / 45 | ± 70 / 45 |

| Number of CNC Axis | 6 | 6 | 6 | 6 | 6 (7th Optional) | 6 (7th Optional) | 6 (7th Optional) | 6 (7th Optional) | 6 | 6 | 6 | 6 | |

| Length | mm | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC |

| Width | mm | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC |

| Height | mm | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC | TBC |

| Weight | kg | 4,500 | 5,000 | 5,500 | 6,000 | 7,000 | 9,000 | 11,000 | 13,000 | 18,000 | 22,000 | 24,000 | 28,000 |

Features

- 3D CNC tube and pipe plasma cutting

- 6 axis CNC

- CAD-CAM integration for importing 3D models

- Oxyfuel or plasma cutting

Options

- Extra axis for square or rectangular material profiling (MO-Classic Only)

Müller Opladen Gmbh have been manufacturing tube and pipe profiling machines since the 1950s. Over the years they have developed machines that offer 3D cutting of pipes and tubes, covering pipe diameters from 50 to 4064 mm ( 2” to 160”).

The pipe profiling and vessel profiling models have a minimum of 6 CNC axes, where 4 axis are required for cutting and the 5th and 6th axis are used for adapting to deviations in the outer pipe diameter. With CAD-CAM integration software CAD files can be uploaded from the office and sent to the machine for profile cutting. Their 3D cutting processes are oxyfuel cutting or plasma cutting and they work with Hypertherm and Kjellberg for their conventional and high definition plasma systems.

Before cutting the machine is probing the pipe to understand where the deviations are that the CNC system has to adapt on during the cutting process. With this technology the 3D pipe profiling machines provide a perfect smooth 3D profile cut on bevels, slots, saddles, mitre cuts and many more profile cut shapes.