Morgan Rushworth XRG Mechanical Guillotine Shear 415v

The Morgan Rushworth XRG powered guillotine shears are designed for high production, precision cutting while at the same time maintaining low operating costs with minimal maintenance requirements. They are very well engineered and are able to sustain production at a high number of cuts per minute without impacting on the cut quality.

All XRG models feature pneumatic sheet supports which give the alternative of dropping cut parts to the front or rear of the machine. If using the return to front system an optional removable trolley can be ordered for easy handling of cut parts.

| MODEL | STOCK CODE | CUTTING LENGTH | CUTTING CAPACITY (MILD STEEL) | CUTTING CAPACITY (STAINLESS STEEL) | CUTTING CAPACITY (ALUMINIUM) | STROKES PER MINUTE | MOTOR | BACKGAUGE TRAVEL (STANDARD) | BACKGAUGE TRAVEL (OPTIONAL) | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | mm | mm | mm | kw | mm | mm | mm | mm | mm | kG | |||

| XRG 2100.30 | M1350 | 2100 | 3.0 | 1.5 | 4.5 | 35 | 4.0 | 750 | 1000 | 2550 | 1950 | 1600 | 1510 |

| XRG 2100.40 | M1351 | 2100 | 4.0 | 2.5 | 6.0 | 35 | 7.5 | 750 | 1000 | 2550 | 1950 | 1600 | 2500 |

| XRG 2550.25 | M1352 | 2550 | 2.5 | 1.5 | 4.0 | 35 | 4.0 | 750 | 1000 | 3150 | 1950 | 1600 | 1690 |

| XRG 2550.40 | M1353 | 2550 | 4.0 | 2.5 | 6.0 | 35 | 7.5 | 750 | 1000 | 3150 | 1950 | 1600 | 2700 |

| XRG 3200.20 | M1354 | 3200 | 2.0 | 1.2 | 3.0 | 35 | 4.0 | 750 | 1000 | 3750 | 1950 | 1600 | 2010 |

| XRG 3200.40 | M1355 | 3200 | 4.0 | 2.5 | 6.0 | 35 | 7.5 | 750 | 1000 | 3750 | 1950 | 1600 | 3050 |

| XRG 4200.15 | M1356 | 4200 | 1.5 | 1.0 | 2.0 | 35 | 4.0 | 750 | 1000 | 4750 | 1950 | 1600 | 2450 |

| XRG 4200.30 | M1357 | 4200 | 3.0 | 2.0 | 4.0 | 35 | 7.5 | 750 | 1000 | 4750 | 1950 | 1600 | 3500 |

Features

- Very rigid welded steel frame

- 2-sided alloy steel blades for mild or stainless steel cutting

- Automatically activated hold down system to prevent sheet sliding during cutting

- 750mm servo powered back gauge, accurate to ± 0.1mm

- Elgo P40T programmable touch screen NC control

- Stainless steel support table with rules in bed

- Retractable front sheet support

- 1000mm squaring arm

- LED illuminated cutting area with shadow line

- Foot pedal control

Options

- Extend Back Gauge Travel to 1000mm

- Extend Squaring Arm to 2 metres

- Extend Squaring Arm to 3 metres

- Blank Sheet Trolley

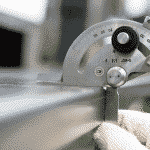

- Angle Gauge

- Laser Cutting Line

Morgan Rushworth XRG Mechanical Guillotine Shear 415v: High-Performance Cutting Solutions

The Morgan Rushworth XRG powered guillotine shears are expertly engineered to meet the demands of high-production environments where precision, efficiency, and reliability are essential. Incorporating cutting-edge technology and robust construction, the XRG range delivers clean, accurate cuts at high speeds, making them ideal for busy workshops, metal fabricators, and industrial applications that demand consistent performance.

Precision and Consistency at High Volumes

The XRG guillotine shears excel in maintaining exceptional cut quality, even during sustained high-volume production. This precision is achieved through their heavy-duty design and meticulous engineering, ensuring clean, burr-free cuts. By delivering smooth edges, these machines eliminate the need for extensive post-processing, such as deburring, making downstream processes like welding, bending, or assembly more efficient. For businesses prioritising quality and productivity, the XRG range is a dependable solution.

Cost-Effective and Durable Design

The XRG guillotines are built to reduce operating costs and minimise maintenance. Featuring long-lasting mechanical components and drive systems, these machines require minimal upkeep, reducing replacement costs and downtime. Despite their powerful performance, the XRG models are highly energy-efficient, helping workshops improve profitability without compromising on output. This combination of durability and efficiency makes them a cost-effective choice for businesses focused on long-term value.

Pneumatic Sheet Supports for Versatility

A standout feature of the XRG guillotines is the inclusion of pneumatic sheet supports. These supports allow cut parts to be dropped either to the front or rear of the machine, providing flexibility to adapt to different workflows and workspace layouts. This functionality ensures that operators can customise the machine to suit specific production requirements, enhancing both efficiency and usability.

For workflows utilising the return-to-front system, cut parts are conveniently delivered back to the front, reducing the need for operators to access the rear of the machine. To further streamline operations, an optional removable trolley can be added, simplifying the collection and transport of cut parts. These thoughtful features improve material handling and minimise manual labour, contributing to uninterrupted workflows.

Optional Accessories for Customisation

The XRG range offers a variety of optional upgrades to meet specific operational needs. CNC-controlled back gauges provide enhanced accuracy and repeatability, allowing for precise cuts and efficient execution of recurring tasks. These programmable back gauges are particularly valuable for complex patterns, saving time and ensuring consistency.

Additional options include extended sheet supports and squaring arms, which are ideal for handling larger sheets. These accessories improve alignment and stability during the cutting process, enhancing both the quality of the cuts and operator comfort. With these upgrades, the XRG guillotines can be tailored to handle a wide range of applications with precision and ease.

Comprehensive Safety Features

Safety is paramount in the design of the XRG guillotine shears. Each model is equipped with protective guards and emergency stop buttons to ensure operator safety and compliance with industry regulations. These features allow operators to halt the machine instantly in case of an emergency, creating a secure working environment. By prioritising safety, Morgan Rushworth ensures peace of mind for operators and workshop managers alike.

Ergonomic and User-Friendly Design

The XRG range features an intuitive control layout designed to maximise operator comfort and productivity. The user-friendly interface simplifies operation, reducing the learning curve for new users and allowing experienced operators to work efficiently. The ergonomic design ensures ease of use during long shifts, making the XRG machines suitable for a wide range of operators, from seasoned professionals to those new to the field.

Built for Durability and High Performance

Constructed from high-quality materials, the XRG guillotine shears are designed for sustained use in demanding environments. Their robust construction and advanced drive systems allow for high-speed precision cutting without compromising on reliability. These machines are built to handle the rigours of frequent use, ensuring consistent performance over time and making them a valuable asset for workshops aiming to optimise operations.

Why Choose the XRG Guillotine Shear Range?

The Morgan Rushworth XRG guillotine shear range stands out for its combination of durability, performance, and user-friendly operation. Key benefits include:

- Exceptional Precision: Burr-free cuts ensure superior quality and minimise post-processing.

- Cost-Effective Design: Durable components and energy efficiency reduce maintenance and operating costs.

- Pneumatic Sheet Supports: Customisable material handling improves workflow flexibility.

- Optional Upgrades: CNC-controlled back gauges and extended supports enhance accuracy and versatility.

- Comprehensive Safety Features: Protective guards and emergency stops ensure operator safety.

Conclusion

The Morgan Rushworth XRG mechanical guillotine shear range sets a new standard for high-performance cutting solutions. Designed for demanding production environments, these machines combine precision, reliability, and cost-effectiveness. With innovative features such as pneumatic sheet supports, optional trolleys, and CNC-controlled back gauges, the XRG guillotines offer unmatched versatility and efficiency. Their robust construction, minimal maintenance needs, and focus on safety make them a long-term investment for businesses seeking to enhance productivity and maintain consistent quality. For workshops and industrial facilities, the XRG range delivers dependable performance that meets the challenges of modern manufacturing.