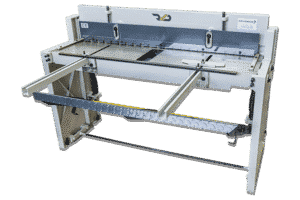

Morgan Rushworth RGMS Mechanical Guillotine Shear 415v

The Morgan Rushworth RGMS range of mechanical guillotines provides fast and accurate cutting of mild steel up to 4mm in thickness. Built for precision and reliability, these machines are ideal for a variety of sheet metalworking tasks and are available in nine different capacities to suit diverse workshop needs.

Equipped with a choice of back gauge systems, users can opt for the standard manually operated back gauge for straightforward operation or upgrade to the advanced Elgo NC back gauge for enhanced automation and precision. This flexibility makes the RGMS range a dependable solution for both small-scale and high-volume cutting applications.

| MODEL | STOCK CODE | CUTTING LENGTH | CUTTING CAPACITY | CUTTING ANGLE | STROKES PER MINUTE | MOTOR | TABLE WIDTH | TABLE HEIGHT | BACKGAUGE ADJUSTMENT | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | mm | kw | mm | mm | mm | mm | mm | mm | kw | ||||

| RGMS 1350/3.0 | M1039 | 1350 | 3 | 2°20′ | 35 | 3 | 420 | 850 | 750 | 1718 | 1370 | 1200 | 965 |

| RGMS 1550/3.0 | M1040 | 1550 | 3 | 2°20′ | 35 | 3 | 420 | 850 | 750 | 1950 | 1370 | 1200 | 990 |

| RGMS 2050/3.0 | M1041 | 2050 | 3 | 2°20′ | 35 | 3 | 420 | 850 | 750 | 2420 | 1370 | 1200 | 1250 |

| RGMS 2550/2.5 | M1042 | 2550 | 2.5 | 1°30′ | 35 | 3 | 420 | 850 | 750 | 2900 | 1370 | 1200 | 1370 |

| RGMS 3050/2.0 | M1043 | 3050 | 2 | 1°30′ | 35 | 3 | 420 | 850 | 750 | 3450 | 1370 | 1200 | 1600 |

| RGMS 1550/4.0 | M1044 | 1550 | 4 | 2°25′ | 41 | 7.5 | 450 | 850 | 750 | 1950 | 2300 | 1300 | 1500 |

| RGMS 2050/4.0 | M1045 | 2050 | 4 | 2°25′ | 41 | 7.5 | 450 | 850 | 750 | 2560 | 2300 | 1500 | 2600 |

| RGMS 2550/4.0 | M1046 | 2550 | 4 | 2°25′ | 41 | 7.5 | 450 | 850 | 750 | 3100 | 2300 | 1500 | 3100 |

| RGMS 3050/4.0 | M1047 | 3050 | 4 | 2°25′ | 41 | 7.5 | 450 | 850 | 750 | 3700 | 2300 | 1500 | 3550 |

Features

- All steel-plate, welded construction provided with static and dynamic frame rigidity

- Rigid cutting beam working inside double bronze guides with graphite

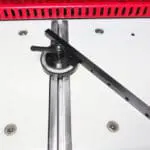

- Precise blade adjustment from top beam

- Mechanical sheet clamping system

- Low-noise, sturdy direct-drive reduction motor

- Easily table-adjusted secure blade gap system

- Shear blades from tough and wear resistant alloyed material

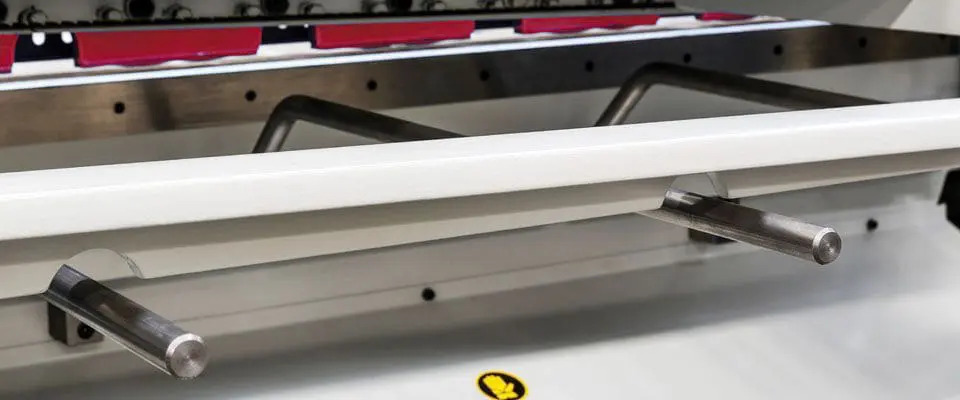

- Front gauging and supports for cutting wide sheets

- Manual back gauge with hand wheel stroke 750mm on 1.5 / 2.0 / 2.5 / 3.0m, stroke 600mm on 1.3m

- Manual blade gap adjustment with position scale

- Switch button to choose from single or repetitive cutting or inching modes

- Foot pedal console with emergency stop button and hand grip to move easily

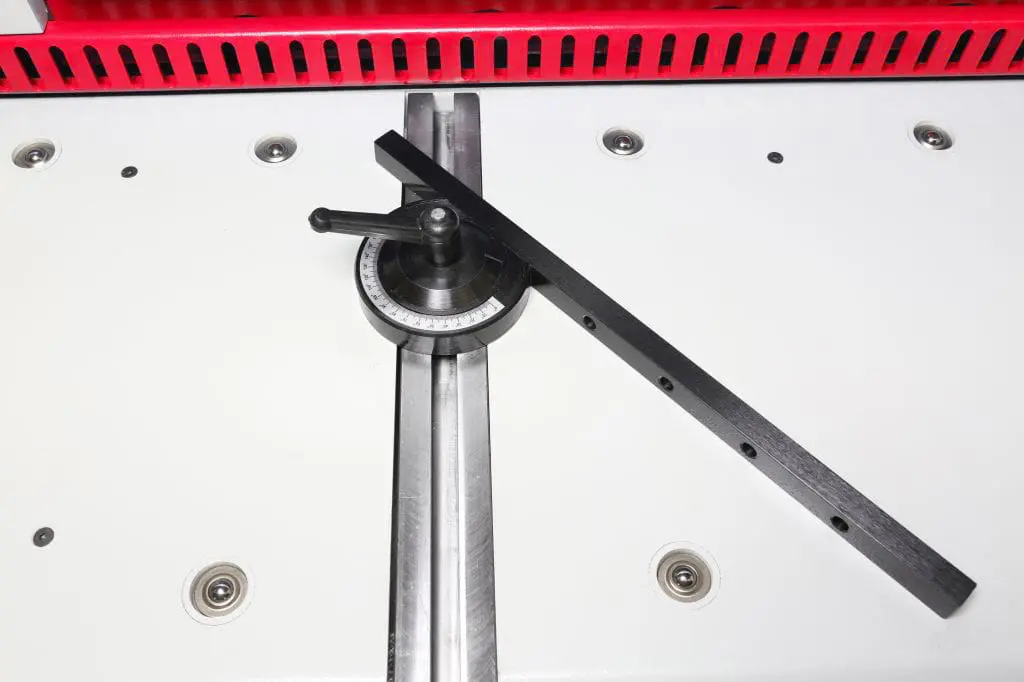

- Squaring arm with scale, T-slot, flip-stop

- Two front support arms

- Hold down beam with rubber pads to protect sheets

- Blades with four cutting edges (bottom blade) and two cutting edges (top blade).

- Protective front and rear cover plates.

- Rear light guard with side fences in accordance with CE regulations

Options

- Power back gauge including digital NC with programmable positioning and piece counter.

- Pneumatic rear sheet support.

- Work table with filler plates and ball transfers

- T-slot and flip-stop on front arms

- Led illumination with shadow line

- Front side collection box up to 300mm pieces

- Central lubrication by hand pump

- Angle gauge with scale 0°-180°

- 1000mm back gauge stroke

- Squaring arm and front support arms other than standard length

Morgan Rushworth RGMS Mechanical Guillotine Shear 415v: Precision and Durability

The Morgan Rushworth RGMS range of mechanical guillotines is specifically designed to deliver fast and accurate cutting of mild steel, with the capability to handle material thicknesses of up to 4mm. These guillotines are built for precision and efficiency, making them an ideal choice for a wide variety of sheet metalworking operations. Whether used in workshops, factories, or high-production facilities, the RGMS range offers reliable performance and robust construction for businesses seeking cutting solutions that stand the test of time.

Flexible Capacities to Suit Every Need

Available in nine different capacities, the RGMS guillotine range provides flexibility to meet the unique requirements of various operations. From smaller workshops managing lower volumes to larger production facilities with demanding schedules, there is an RGMS model to suit every need. Powered by a dependable 415-volt supply, these machines deliver consistent and powerful performance, ensuring efficient cutting of mild steel sheets across all capacities.

Precision Cutting for High-Quality Results

A standout feature of the RGMS guillotines is their exceptional cutting precision. The heavy-duty construction ensures stability, minimising vibrations during operation and resulting in clean, burr-free cuts. This accuracy is critical for industries where precision is paramount. Equipped with durable, high-quality steel blades, the RGMS machines maintain their sharpness over prolonged use, reducing the need for frequent replacements. This not only lowers maintenance costs but also increases operational uptime, ensuring reliable performance.

Back Gauge Options for Enhanced Control

To provide versatility and user control, the RGMS guillotine range offers two back gauge options:

- Standard Manually Operated Back Gauge:

This straightforward solution is perfect for operators who prefer hands-on control. The manual back gauge allows for quick adjustments, making it an excellent choice for smaller workshops or facilities with varying cutting requirements. - Optional Elgo NC Back Gauge:

For those seeking to streamline their processes, the advanced Elgo NC back gauge is a valuable upgrade. This system introduces automation, allowing operators to input and store specific measurements for recurring tasks. With advanced programming capabilities, it saves time, reduces human error, and ensures precise, repeatable cuts, ideal for high-production environments.

Safety Features for Operator Protection

Safety is a key priority in the design of the RGMS range. All models are equipped with industry-standard safety features, including:

- Protective Guards: Prevent accidental contact with the blades.

- Emergency Stop Buttons: Allow immediate shutdown in case of an issue.

These safety measures ensure compliance with workplace safety regulations, giving operators peace of mind while using the equipment.

Ergonomic Design for User Comfort

The RGMS guillotines are designed with operator convenience in mind. The intuitive control layout and clear visibility of the cutting area enhance the user experience, enabling efficient operation without unnecessary strain. A robust foot pedal control frees the operator’s hands for precise material handling and positioning, making the cutting process smooth and straightforward.

Optional Accessories for Enhanced Productivity

To maximise productivity, the RGMS guillotine range can be complemented with optional features and accessories, including:

- Front Support Arms: Improve material handling for larger sheets.

- Side Gauges: Aid in alignment for precise cuts.

These optional extras are particularly beneficial when working with larger or heavier steel sheets, ensuring accuracy and ease of use.

Built for Durability and Reliability

The RGMS guillotine range is engineered with rugged steel frames and high-quality components to withstand the demands of daily use in industrial environments. The robust mechanical drive system, powered by a durable motor, ensures consistent performance over time. With minimal moving parts, these machines are less prone to mechanical failures, reducing downtime and maintenance costs. This durability makes the RGMS range a cost-effective, long-term investment.

Applications Across Industries

The Morgan Rushworth RGMS mechanical guillotine shear is suitable for a wide range of industries, including:

- Manufacturing: Cutting components for production lines.

- Fabrication: Preparing materials for assembly or welding.

- Metalworking: Shaping and resizing steel sheets for various projects.

Its versatility, combined with high precision and robust performance, ensures that the RGMS range meets the needs of diverse applications.

Why Choose the RGMS Guillotine Range?

The Morgan Rushworth RGMS guillotine range combines quality engineering, advanced features, and user-friendly operation. Key benefits include:

- High-Precision Cutting: Clean, burr-free results with minimal maintenance.

- Flexible Capacities: Options to suit both small and large-scale operations.

- Safety Features: Ensures compliance with workplace regulations.

- Optional Upgrades: Advanced back gauge systems and accessories for enhanced functionality.

This thoughtful design makes the RGMS range a dependable choice for businesses aiming to optimise their cutting processes.

Conclusion

The Morgan Rushworth RGMS mechanical guillotine shear range exemplifies precision, durability, and efficiency. From its robust construction and high-quality blades to its advanced back gauge options and user-friendly design, the RGMS range delivers exceptional performance for a wide variety of applications. For businesses seeking a reliable, versatile, and cost-effective cutting solution, the RGMS guillotine range is a proven investment that enhances productivity, ensures consistent quality, and provides long-term value.