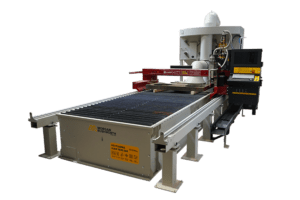

Morgan Rushworth HDP High-Definition CNC Plasma Cutting Machines

The Morgan Rushworth HDP Range of Hyperformance High Definition XD CNC plasma cutting machines offers dross-free cutting of mild steel, stainless steel, and aluminium. Featuring the advanced Hypertherm Hyperformance plasma unit, these machines deliver fast production and high-quality results.

The Hypertherm MicroEDGE CNC controller supports DXF and DWG files via disk, USB, or Ethernet. Preloaded shapes can also be edited and visualised on the LCD screen. An optional extraction/filtration system is available or can be connected to an existing factory ducted system.

| MODEL | 1503/130 | 2004/130 | 2006/130 | 1503/260 | 2004/260 | 2006/260 | |

| Plasma Output | Amps | 30-130 | 30-130 | 30-130 | 30-260 | 30-260 | 30-260 |

| Production Pierce Capacity | |||||||

| Mild Steel | mm | 25 | 25 | 25 | 40 | 40 | 40 |

| Stainless Steel | mm | 20 | 20 | 20 | 25 | 25 | 25 |

| Aluminium | mm | 20 | 20 | 20 | 25 | 25 | 25 |

| Maximum Cutting Capacity | |||||||

| Mild Steel | mm | 30 | 30 | 30 | 65 | 65 | 65 |

| Stainless Steel | mm | 25 | 25 | 25 | 50 | 50 | 50 |

| Aluminium | mm | 25 | 25 | 25 | 50 | 50 | 50 |

| X Axis Stroke | mm | 1500 | 2000 | 2000 | 1500 | 2000 | 2000 |

| Y Axis Stroke | mm | 3000 | 4000 | 6000 | 3000 | 4000 | 6000 |

| Length | mm | 5900 | 7250 | 9100 | 5900 | 7250 | 9100 |

| Width | mm | 3365 | 3865 | 3865 | 3365 | 3865 | 3865 |

The Table Size can range from 1500 x 3000mm – 6000 x 36000mm depending on your requirements.

Features

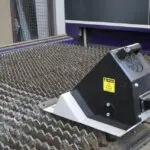

- HyPerformance High Definition plasma cutting technology for unmatched reliability

- Advanced XD technology with patented LongLife®, PowerPierce® and with optional equipment TrueHole™ capability

- Hypertherm automatic gas console

- Hypertherm torch height control

- Superior consistent quality dross free finish without the requirement for secondary operation

- Maximised productivity with minimised operating costs

- Electrical current and gas pressure applied in a gradual controlled manner at the beginning and at the end of the cut resulting in an increase of seamable life of six to eight times greater than comparable traditional systems

- High efficiency Hypertherm plasma unit and windows based MicroEDGE Pro CNC controller to ensure perfect operational harmony

- Hypertherm ProNest 2012 nesting software

- 180mm touch screen LCD display

- Large range of standard table sizes, with special sizes available on request

- Strong steel frame designed to withstand constant high speed production

- X and Y axis travel on precision linear guide rails

- Fast positioning with Siemens brushless AC servo motor

- Positioning accuracy to 0.01mm

- Automatic torch ignition and height control

- Arc voltage feedback to control optimum torch height position

- Mechanical and electronic collision avoidance system

- Marking and cutting of material performed with the same plasma torch

- Torch can be set manually to bevel up to 45 degrees

- Fume extraction system beneath the table with exhaust connection at rear of machine that can be connected to factory extraction system or to optional filtration unit

Options

- Single station drilling head (requires EDGE Pro control)

- Three station drilling head (requires EDGE Pro control)

- Six station drilling head (requires EDGE Pro control)

- Bevel cutting plasma head (increases bed width by 500mm. Requires EDGE Pro control)

- CNC tube plasma attachment (requires EDGE Pro control)

- Upgrade to Hypertherm EDGE Pro CNC control

- Extraction/filtration unit

- Auto nesting software

Morgan Rushworth HDP High-Definition CNC Plasma Cutting Machines

The Morgan Rushworth HDP range of Hyperformance High-Definition XD CNC plasma cutting machines is designed to deliver precision, speed, and reliability. With the ability to cut mild steel, stainless steel, and aluminium with dross-free results, these machines are ideal for demanding industrial applications. Whether your focus is high production output or intricate cutting tasks, the HDP range offers exceptional performance across the board.

Advanced Hypertherm Plasma Technology

At the core of the HDP range is the Hypertherm Hyperformance plasma unit, a state-of-the-art technology renowned for its cutting-edge capabilities. This plasma unit provides:

- Exceptional cut quality: Achieve precise, smooth edges with minimal post-processing required.

- Fast production speeds: Significantly reduce cutting times, increasing overall efficiency.

- Versatility across materials: Effortlessly handle a variety of thicknesses in mild steel, stainless steel, and aluminium.

- Dross-free cutting: Eliminate the need for extensive cleanup, saving time and labour costs.

This advanced plasma technology ensures that every cut is clean and accurate, making it a reliable solution for industries requiring high-performance machinery.

User-Friendly CNC Controller

The Morgan Rushworth HDP machines are equipped with the Hypertherm MicroEDGE CNC controller, which simplifies the cutting process while offering robust features for professional use. Key highlights include:

- Support for DXF and DWG files: Operators can easily import cutting designs via disk, USB, or Ethernet connections.

- Preloaded shape library: Access a range of commonly used shapes, which can be edited and visualized directly on the LCD screen.

- Intuitive interface: The user-friendly design reduces operator training time and ensures seamless workflow integration.

The controller’s advanced capabilities streamline the setup and cutting process, making it an efficient tool for both novice and experienced operators.

Cutting Edge Performance and Reliability

The HDP range is engineered to deliver outstanding cutting performance, even in the most demanding environments. With robust construction and high-quality components, these machines ensure:

- Consistent accuracy: Maintain precise cuts over extended production runs.

- Durability: Built to withstand the rigours of daily industrial use.

- Reduced downtime: The reliable design minimises maintenance requirements, allowing for uninterrupted operation.

Efficient Material Handling

The Morgan Rushworth HDP machines are designed with material handling efficiency in mind. Key features include:

- Large cutting tables: Accommodate oversized sheets and plates for maximum versatility.

- Easy loading and unloading: Reduce setup times and improve workflow efficiency.

- Optimised nesting capabilities: Enhance material usage and minimise waste with the integration of advanced nesting software.

Optional Extraction and Filtration Systems

To maintain a safe and clean working environment, the HDP range offers optional extraction and filtration systems. These systems can either be standalone units or integrated into an existing factory ducted system, ensuring compliance with workplace safety regulations and improving air quality.

Applications Across Industries

The versatility of the HDP machines makes them suitable for a wide range of industries, including:

- Fabrication and manufacturing: For creating structural components and custom parts.

- Automotive: Precision cutting for parts and assemblies.

- Construction: Producing large-scale steel structures and frameworks.

- Shipbuilding: Cutting complex shapes and profiles for marine applications.

Cost Efficiency and ROI

By combining high-speed cutting with dross-free results, the Morgan Rushworth HDP machines significantly reduce production times and post-processing costs. The energy-efficient design and long-lasting components further contribute to cost savings, ensuring a strong return on investment for your business.

Customisation Options

To meet specific operational needs, the HDP range can be tailored with a variety of optional features, including:

- Upgraded power sources: For increased cutting thickness capabilities.

- Automatic height control: Ensuring consistent cut quality across varying material surfaces.

- Integrated software upgrades: Enhance functionality and optimise productivity.

Conclusion

The Morgan Rushworth HDP High-Definition CNC Plasma Cutting Machines set a new standard for precision and efficiency in plasma cutting. With advanced Hypertherm technology, a user-friendly CNC controller, and robust construction, these machines are an excellent investment for businesses seeking reliable, high-performance cutting solutions. Whether your priority is speed, quality, or versatility, the HDP range delivers unmatched results that meet the demands of modern industry.

Choose the Morgan Rushworth HDP range to elevate your cutting capabilities and achieve superior outcomes with every project.