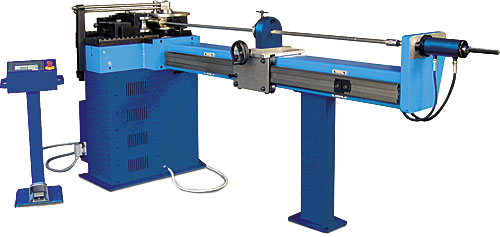

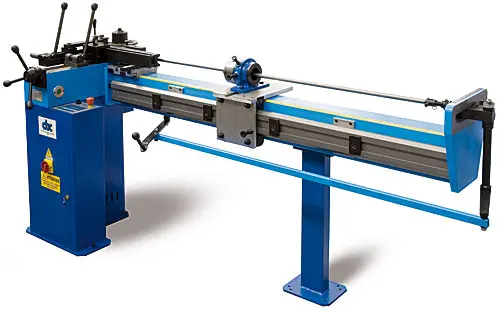

CBC UNI Mandrel Tube Bender

The CBC range of mandrel tube bending machines have been designed to meet the requirement to bend thin wall tube to tight radii. The mandrel is positioned at the point of bend to prevent wrinkling on the inside and flattening on the outside. A slider guide moves in tandem with the tube to prevent marking, particularly to decorative material such as stainless steel.

The UNI 63 model has manual mandrel extraction and manual clamping of the tube during the bend, and is designed to bend tube to a minimum radius of 2 times the tube diameter. Other models are available in the range to accommodate larger tube diameters and even tighter bending radii.

| Model | UNI 63 | UNI 70/C | UNI 70/C-OS | UNI 70/HC | UNI 70 HC-OS | UNI 80 | UNI 90 |

|---|---|---|---|---|---|---|---|

| Stock Code | 21643 | 21637 | 21367/C-OS | 21365 | 21365/OS | 21366 | 21367 |

| Capacity (Mild Steel) | 35 x 2 mm | 50 x 4 mm | 50 x 3 mm | 50 x 4 mm | 50 x 3 mm | 76 x 1.5 mm | 90 x 3 mm |

| Max. Bending Angle | 180 | 180 | 180 | 180 | 180 | 180 | 180 |

| Motor | 1.5 Kw | 1.5 / 2.2 Kw | 1.5 / 2.2 Kw | 2.3 / 3.1 Kw | 2.3 / 3.1 Kw | 3.0 Kw | 4.0 Kw |

| Standard Mandrel Length | 1,000 mm | 2,000 mm | 2,000 mm | 2,000 mm | 2,000 mm | 3,000 mm | 3,000 mm |

| Optional Mandrel Lengths | 2,000 / 3,000 / 4,000 mm | 3,000 / 4,000 / 5,000 / 6,000 mm | 3,000 / 4,000 / 5,000 / 6,000 mm | 3,000 / 4,000 / 5,000 / 6,000 mm | 3,000 / 4,000 / 5,000 / 6,000 mm | 2,000 / 4,000 / 5,000 / 6,000 mm | 4,000 / 5,000 / 6,000 mm |

| Min. Length of First Bend | 120 mm | 120 mm | 120 mm | 130 mm | 130 mm | 150 mm | 200 mm |

| Programs | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Bends / Program | 9 | 9 | 9 | 9 | 9 | 9 | 9 |

| Length | 740 mm | 810 mm | 810 mm | 830 mm | 830 mm | 830 mm | 1,110 mm |

| Width | 900 mm | 400 mm | 400 mm | 630 mm | 630 mm | 630 mm | 700 mm |

| Height | 1,000 mm | 1,100 mm | 1,100 mm | 1,270 mm | 1,270 mm | 1,270 mm | 1,310 mm |

| Weight | 120 Kg | 210 Kg | 210 Kg | 400 Kg | 400 Kg | 600 Kg | 970 Kg |

Features

- 1m Mandrel system (UNI 63)

- 2m Mandrel system (UNI 70 Models)

- 3m Mandrel system (UNI 80 & 90 Models)

- Quality bending of thin wall tubes

- Bending radii to 2 x tube diameter

- Bend a wide range of materials including stainless steel

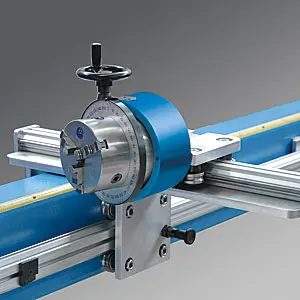

- Plane of bend indicator with positioning stops

- Manual mandrel extraction

- Manual clamping of tube to former

- Interchangeable tool post to support small radius bending applications

- Programmable bending angle with 50 memories with 9 phases per memory

Options

- Full range of tooling including formers, wiper dies, slider dies and counter formers

- Alternative mandrel lengths up to 6 metres

CBC UNI Mandrel Tube Benders – Precision, Power & Durability

The CBC UNI mandrel tube bending machines are expertly engineered to bend thin-wall and larger-diameter tubes into tight radii with exceptional quality. Featuring a mandrel placed at the bend point to eliminate wrinkling and maintain consistent wall thickness, plus a slider guide that moves with the tube to prevent surface marking, they deliver pristine results—especially on finishes like stainless steel.

Key Benefits

-

Wrinkle-free bends: Internal mandrel supports prevent inward collapse of the tube, while external formers guard against flattening.

-

Surface protection: The guided slider die ensures scratch-free bending—vital for decorative, polished finishes.

-

Programmability: Digital models store up to 50 programmes with 9 bends each.

-

Space efficient: Compact footprints allow these machines to fit into most production environments without sacrificing capacity.

Desktop of Models

UNI 63

-

Capacity: Mild steel 35 × 2 mm, stainless steel 30 × 2 mm

-

Radius: Bends down to 2× tube diameter

-

Mandrel system: 1 m manual extraction, manual clamping

-

Drive: 1.1 kW motor; programmable 50×9

-

Ideal for: Light fabrication, custom work where tight, delicate bends are required.

UNI 70/C (and OS variants)

-

Capacity: Mild steel 50 × 4 mm, stainless 50 × 3 mm

-

Radius: Minimum 2.5× tube diameter

-

Mandrel: Manual extraction, manual clamp; available with 2-speed motor (1.5 / 2.2 kW)

-

Control: Digital unit stores up to 70 programs, auto-return included

-

Use cases: Plumbing, hydraulics, industrial, marine—ideal for larger-diameter tubing

UNI 70/HC, HC‑OS, UNI 80, UNI 90

Tailored for even larger diameters and thicker walls, these high-capacity models feature hydraulic mandrel extraction and tube clamping, programmable controls, and dual-speed motors.

-

UNI 70/HC & HC‑OS: Middle range

-

UNI 80: Up to ~76 mm OD

-

UNI 90: Heavy-duty use (includes motor up to 4.0 kW)

Why Choose CBC UNI Benders?

-

Wide material compatibility – perform flawlessly on mild steel, stainless steel, aluminium, brass, CDS, T45, etc.

-

Precision and consistency – digital programmes, auto-return, positioning stops, and counter formers ensure repeatable accuracy.

-

Scalable to your needs – models from entry-level UNI 63 to heavy-duty UNI 90 deliver progressive capacity and features.

-

Durability & support – Italian-engineered robustness with global servicing and tooling options.

Perfect Applications

-

Decorative tube work in kitchens, medical equipment, and architectural fixtures

-

Hydraulic & plumbing assemblies requiring tight, controlled bends

-

Furniture manufacture for frames and rails with aesthetic finishes

-

Industrial and marine systems with larger-diameter tubing

Summary

The CBC UNI range combines thoughtful engineering with versatile capability—bending anything from delicate, thin-walled tubing to substantial, thick-walled pipes. Models scale intuitively in capacity and sophistication:

-

UNI 63: Manual precision for tight, small-diameter bends

-

UNI 70/C: Digital control, multi-speed drives, broader material range

-

HC/HC‑OS, 80, 90: Hydraulic simplicity, heavy-duty heft, industrial-grade output

Regardless of your workshop size or production volume, there’s a CBC UNI tailored to deliver clean, accurate bends consistently.