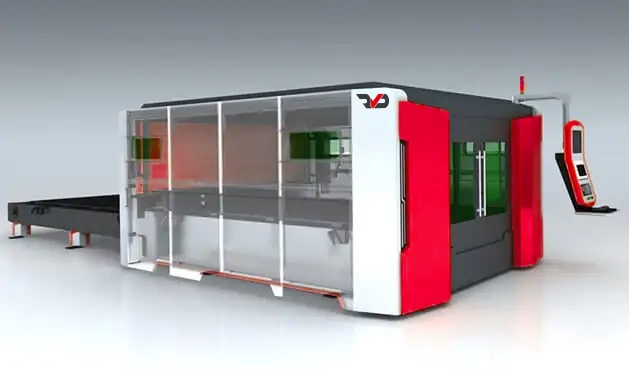

RVD PRT SmartFibre Combination Laser

The RVD PRT SmartFibre Combination Laser features a fully enclosed protective cover, an exchange shuttle table, and a rotary attachment for tube cutting. It is capable of processing both metal sheets and tubes on the same machine.

The advanced CNC laser cutting system, combined with high-quality components and a meticulous assembly process, ensures safe and stable operation, exceptional cutting efficiency, and high precision.

| Laser Power | kW | 1.5 – 6 |

| Laser Source | Max Photonics | |

| Processing Surface (L x W) | mm | 1500 x 3000 |

| CNC Control | CypCut / CupTube | |

| Laser Head | BOCI | |

| Position Accuracy X, Y and Z Axis | mm | ±0.05 |

| Repeat Position Accuracy X, Y and Z Axis | mm | ±0.03 |

| Maximum Position Speed of X and Y Axis | mm/min | 80 |

| Maximum Acceleration | G | 1.2 |

| Max Load of Table | kg | 900 |

| X Axis Travel | mm | 3,050 |

| Y Axis Travel | mm | 1,535 |

| Z Axis Travel | mm | 280 |

| Front Chuck | Automatic (Pneumatic Type) | |

| Feeding Chuck | Automatic (Pneumatic Type) | |

| Tube Diameter | mm | Round – Ø 20 – 240 Square – 20 – 240 x 240 |

| Tube Length | mm | 6,000 |

| Length | mm | 8,785 |

| Width | mm | 2,280 |

| Height | mm | 2,429 |

| Weight | kg | 5,500 |

RVD Laser Cutting Capacity Table

| Laser Power | kW | 1.5 | 2 | 3 | 4 | 6 |

| Cutting Capacity – Mild Steel | mm | 14 | 20 | 22 | 25 | 25 |

| Cutting Capacity – Stainless Steel | mm | 6 | 10 | 12 | 12 | 20 |

| Cutting Capacity – Aluminium | mm | 5 | 8 | 10 | 12 | 16 |

| Cutting Capacity – Brass | mm | 5 | 8 | 8 | 12 | 14 |

| Cutting Capacity – Copper | mm | 4 | 6 | 6 | 6 | 10 |

| Cutting Capacity – Galvanised Mild Steel | mm | 5 | 6 | 8 | 10 | 14 |

Features

- High performance Max Photonics Laser Source

- Fibre optic beam delivery system

- BOCI Autofocus Laser Cutting Head

- High strength, rigid gantry design to ensure high accuracy and allow high acceleration

- High precision class alpha rack and pinion drive motion system

- Shuttle Exchange Table

- Applicable tube types : Round tube, square tube, rectangular tube, oval tube, D-shaped steel, T-shaped steel, H-shaped steel, channel steel, angle steel, etc.

- CE compliant complete machine enclosure and light barrier system

- CupCut / TubePro CAD/CAM Software

- FSCUT 3000 CNC Controller

Options

- 3m / 6m Tube Cutting Capacity

- Filtration & Extraction

RVD PRT Combination Fibre Laser Cutting Machine: Sheet and Tube Cutting in One Powerful System

The RVD PRT Combination Fibre Laser is a high-performance laser cutting solution engineered to handle both sheet and tube materials with ease, precision, and efficiency. Designed with versatility and operator safety in mind, this advanced CNC laser cutting machine combines a fully enclosed cutting environment, a high-speed exchange shuttle table, and a rotary tube cutting attachment – all integrated into a single compact footprint.

Built to meet the demands of modern fabrication shops, this dual-purpose laser cutter is ideal for manufacturers working with varied material formats and profiles. Whether you’re processing mild steel, stainless steel, aluminium or more complex tubular profiles such as square, rectangular, oval, or D-shaped steel, the RVD PRT delivers accurate, consistent results across the board.

Fully Enclosed Class 4 Laser Cutting System

Safety is a top priority, and the RVD PRT is fully enclosed in line with UKCA and CE Class 4 laser regulations, ensuring the highest level of protection for operators. The enclosure covers both the flatbed sheet cutting table and the integrated rotary tube cutting unit, offering a sealed, controlled cutting environment that also facilitates efficient fume extraction and dust containment. This design not only meets regulatory compliance but enhances productivity and workplace cleanliness.

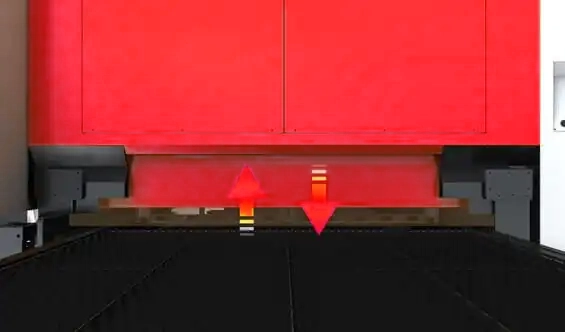

Automatic Lift Door with Safety Benefits

The machine is equipped with an automatic lift door that further enhances safety and usability. This feature minimises laser radiation leakage and creates a secure cutting chamber, ideal for working with highly reflective materials such as aluminium and copper. The enclosed environment simplifies the extraction of smoke and particulates, helping maintain a clean workshop and prolonging the life of internal components.

One Gantry, Two Processes – Maximising Efficiency

A key feature of the RVD PRT is its single gantry system, which supports both flatbed and tube cutting functions using the same laser torch. This shared infrastructure significantly reduces the machine’s overall footprint, saving valuable workshop space while eliminating the need for two separate machines. The design also improves production speed by reducing setup times and allows for more seamless transitions between processes.

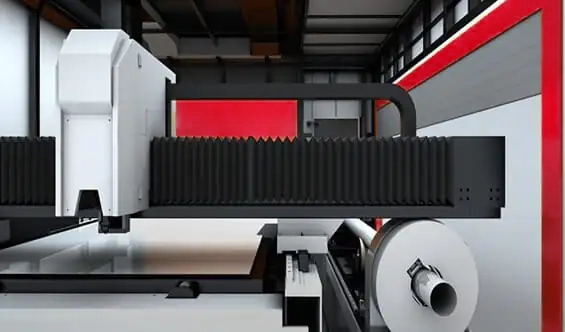

Heavy-Duty Plate-Welded Frame

The RVD PRT is built on a thick steel plate-welded base, with a structure up to 18mm thick, offering unmatched rigidity and durability. This robust base reduces vibrations during high-speed cutting operations, ensuring long-term accuracy and repeatability. The added weight of the machine also contributes to its stability, increasing overall service life and performance under continuous operation.

Premium Components and High-Speed Cutting Performance

Every component of the RVD PRT Combination Laser is selected for its performance and reliability. At its core is a high-performance Max Photonics fibre laser source, delivering powerful, stable output via a fibre optic beam delivery system. The machine is fitted with a BOCI autofocus laser cutting head, ensuring precise focus adjustments in real-time for varying material thicknesses and surface conditions.

Motion is handled by a high-strength, rigid gantry and Class Alpha precision rack and pinion drive system, providing excellent positioning accuracy and allowing for high-speed acceleration during cutting cycles. The integrated FSCUT 3000 CNC control system delivers intuitive, real-time control over all machine operations, supported by advanced CupCut and TubePro CAD/CAM software for fast nesting, toolpath generation and job setup.

Built-In Shuttle Table and Tube Cutting Capability

The exchange shuttle table enables simultaneous loading and unloading while cutting is in progress, significantly reducing downtime and improving throughput. The tube cutting attachment is compatible with a wide range of profiles including round, square, rectangular, oval, D-shaped, T-section, H-section, angle and channel steel. This makes the machine ideal for applications in general metal fabrication, construction, agriculture, automotive and structural engineering sectors.

CE Compliant Safety Systems

In addition to its full enclosure, the RVD PRT is equipped with a CE-compliant light barrier system, which adds an extra layer of protection around the working area. These features ensure that the machine meets the highest standards for occupational health and safety, without compromising productivity.

Optional Add-Ons and Customisation

To meet different production requirements, the RVD PRT can be configured with either a 3-metre or 6-metre tube cutting capacity, allowing users to tailor the machine to the size and type of work undertaken. An optional filtration and extraction system is also available to enhance fume control and air quality, especially in enclosed workshops or high-volume environments.

The Ideal Choice for Multi-Format Laser Cutting

In summary, the RVD PRT Combination Fibre Laser Cutting Machine offers a robust, compact and cost-effective solution for businesses seeking to cut both sheet and tube materials with high precision. Its combination of advanced technology, safety features, intelligent design, and premium components makes it a standout choice for modern metalworking operations aiming to streamline their workflow and expand their capabilities.