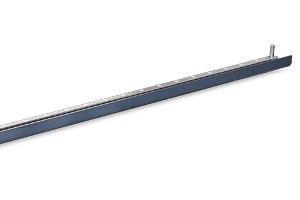

PEHU LMS 80 Automatic Measuring System with Digital Readout

The PEHU LMS80 is the most advanced and heavy-duty model in the range, built for large-scale applications requiring maximum capacity and automation. With stop positions easily programmed via the NC control, the LMS80 delivers fast, accurate measuring and feeding across a wide range of machinery, including saws, drills, punching machines, and steelworkers.

Designed for the most demanding production environments, the LMS80 offers superior strength, precision, and automation over the LMS30, LMS45, and LMS60. The full range also includes the manual LMS15, which can be upgraded with a controller – offering a practical starting point for workshops beginning their automation journey.

| MODEL | Servo Control | Measuring Operation | Flip-Up Stop Operation | Set-Up | Width | Base Length | Additional Lengths | Positioning Accuracy | Positioning Speed |

| mm | mm | m | mm | m/min | |||||

| PEHU LMS15-04 | N/A – Manual | Manual + DRO | Manual | Attaches to existing roller track system | 350 | 4,000 (3.6m working length) | +1m per length | +/- 0.2 mm | Manual |

| PEHU LMS15-04 + 112S (3.3) | 112S 3.3Nm Servo Control | Semi-Automatic (Stroke Control) | Manual | Attaches to existing roller track system | 350 | 4,000 (3.6m working length) | +1m per length | +/- 0.2 mm | Manual |

| PEHU LMS30-04 + 112S (3.3) | 112S 3.3Nm Servo Control | Semi-Automatic (Stroke Control) | Manual | Attaches to existing roller track system | 350 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS30-04 + 112 (3.3) | 112 3.3Nm Servo Control | Fully Automatic | Manual | Attaches to existing roller track system | 350 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS45-04 + 112S (3.3) | 112S 3.3Nm Servo Control | Semi-Automatic (Stroke Control) | Manual | Attaches to existing roller track system | 630 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS45-04 + 112 (3.3) | 112 3.3Nm Servo Control | Fully Automatic | Manual | Attaches to existing roller track system | 630 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS45-04 + 112 (5.0) | 112 5.0Nm Servo Control | Fully Automatic | Manual | Attaches to existing roller track system | 630 | 4,000 (3.6m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS60-06 | 112 5.0Nm Servo Control | Fully Automatic | Hydraulic / Electric | Integrated into a seperate dedicated frame | 830 | 6,000 (4.5m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

| PEHU LMS80-06 | 112 5.0Nm Servo Control | Fully Automatic | Hydraulic / Electric | Integrated into a seperate dedicated frame | 1,100 | 6,000 (4.5m working length) | +1m per length | +/- 0.1 mm | +/- 40 |

Features

- Lengths: base 6 m (4.5 m working length), can be extended per meter

- Stop: hydraulic-electric folding

- Position/repeat accuracy: ± 0.1 mm

- Position speed: ± 40 m/min (depending on gearbox)

- Mounting: free-standing frame

- Coating: textured powder coating RAL 7016 (dark grey) RAL 9006 (light grey)

Options

- Powered Flip-Up Stop: Facilitates the handling of longer materials

- Material Clamps: Available in pneumatic or hydraulic variants to secure materials during processing

- Material Stop Warning Lamp: Provides a visual indicator when material contacts the stop

- Control Display in Arm: Offers flexible positioning of the control interface for operator convenience

- Interconnection Kit: Enables integration with processing machines for enhanced automation

- Extension Kits: Allow for the extension of the PEHU rail to accommodate longer materials

- Roller Tracks: Available in gravity or powered configurations to suit specific requirements

- 1000mm Steel Finger: Extend the stop past your roller track for smaller parts cutting (can be cut down to suit)

- 1600mm Steel Finger: Extend the stop past your roller track for smaller parts cutting (can be cut down to suit)

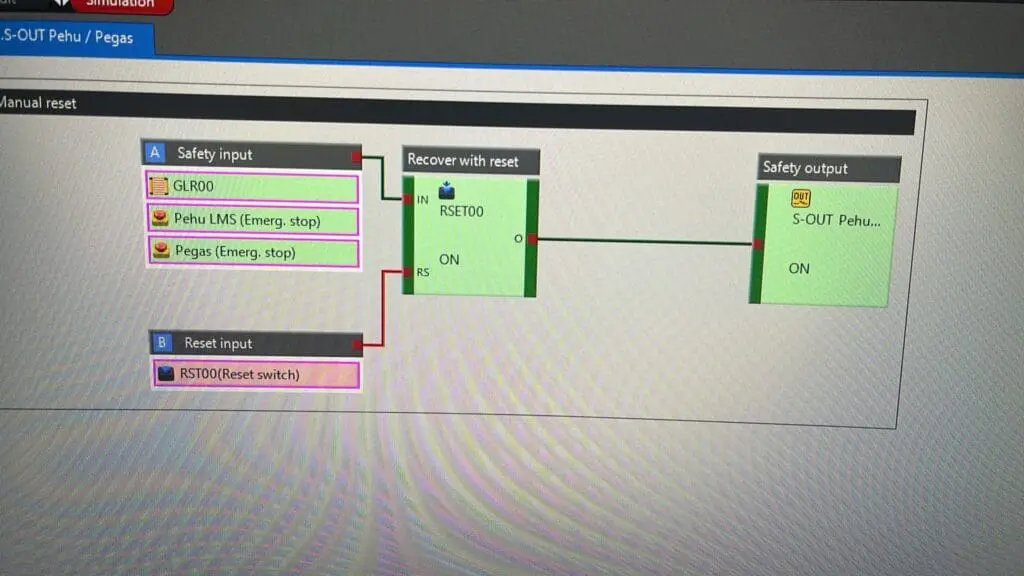

- Hold-to-run Safety System: For ultimate user safety, a hold-to-run safety system ensures your hands / operator are always out of the way.

- Light Guard Safety System: Enhances operator safety during machine operation

PEHU LMS30 to LMS80 Length Measuring Systems

The PEHU LMS30 to LMS80 range comprises advanced powered measuring systems, configurable as either auto-measuring or auto-feeding systems. These solutions enhance productivity by automating material positioning tasks. Operators simply enter the required stop positions via the NC control, and the system will automatically execute the program sequence until completion.

These systems can be configured for use with saws, drills, steelworkers, or punching machines, and offer varying levels of capacity, automation, and control depending on the chosen model.

PEHU LMS30 – For Light to Medium-Duty Workflows

- Ideal for sawing, drilling, punching, and shearing machines

- Can be positioned to the left or right of the machine

- Standard: 4m angle line with 30mm linear guide, extendable

- Stop carriage with backlash-free linear guides and manual folding stop

- Compatible with existing roller conveyors

Controls:

- Standard: PEHU 112S – 3.3 Nm semi-automatic servo control

- Optional: PEHU 112 – 3.3 Nm fully automatic push-up control

PEHU LMS45 – Step Up to Medium & Heavy-Duty Material Handling

- Suitable for use with sawing, drilling, punching, and shearing machines

- Mountable on either side of the machine

- Standard: 4m angle line with 45mm linear guide, extendable

- Stop carriage with two linear guides and manual folding stop

- Easy mounting to existing roller conveyors

Controls:

- Standard: PEHU 112S – 3.3 Nm semi-automatic control

- Optional: PEHU 112 – 3.3 Nm or 5.0 Nm fully automatic control

PEHU LMS60 – Heavy-Duty Accuracy for Demanding Environments

- Designed for high-accuracy positioning in heavy-duty industries

- Works on both sides of sawing machines

- Built on a robust UNP frame

- Supplied with hydraulic or electric folding stop

- Includes sensors to slow roller conveyors and confirm stop engagement

Controls:

- Standard: PEHU 112 – 5.0 Nm servo control

- Used as a 1-axis point-to-point stop system

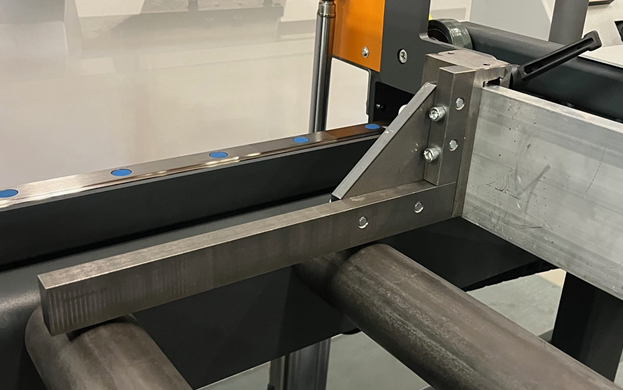

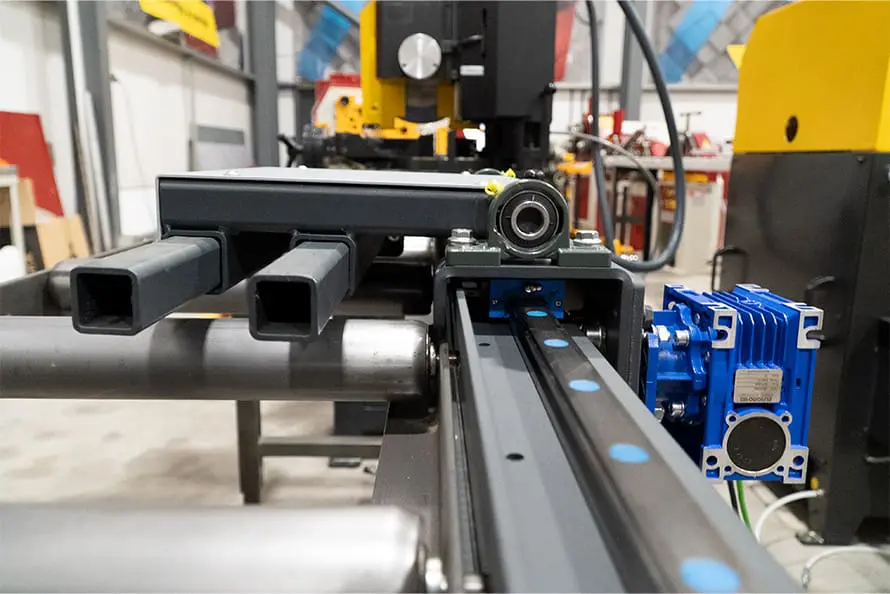

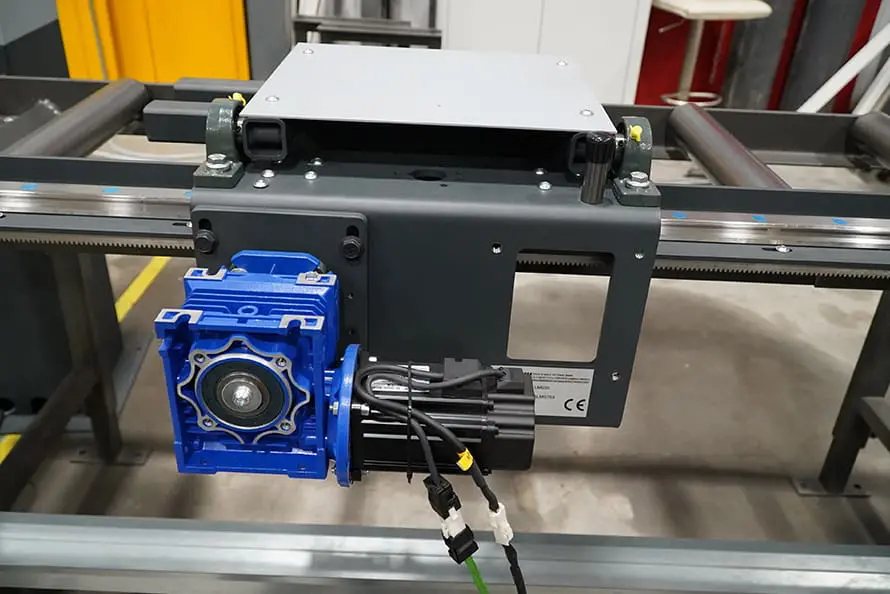

PEHU LMS80 – Unmatched Strength for Industrial Giants

- Ideal for extremely heavy materials requiring precise positioning

- Works on either side of the sawing machine

- Includes heavy-duty UNP frame and servo-controlled folding stop

- Equipped with sensors for conveyor control and visual confirmation

Controls:

- Standard: PEHU 112 – 5.0 Nm servo control

- 1-axis NC point-to-point operation for optimal accuracy

Optional Extras

PEHU Extension:

All systems are extendable by the metre. Each extension includes:

- Special powder-coated angle line (Ral 7016)

- Linear rail, rack, cable duct and carrier

PEHU Automatic Folding Stop:

- Standard manual folding stop (LMS15/30/45)

- Gas spring assist available for LMS15/30/45

- Electric folding stop available for LMS45

- Hydraulic/electric folding stop standard on LMS60/80

PEHU Material Stop Light:

- Lights up when material contacts the stop – helpful for long lengths

PEHU Material Clamp:

- Prevents rolling during pushing

- Adjustable width with manual, pneumatic, or hydraulic options

PEHU Control Display in Arm:

- Adjustable-angle display on hinged mount

- Max 8m cable length from control cabinet

PEHU Interconnection Kit:

- Enables communication between the PEHU system and processing machine

- Converts semi-automatic to fully automatic operation or automates manual machines