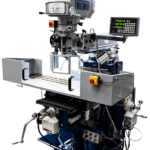

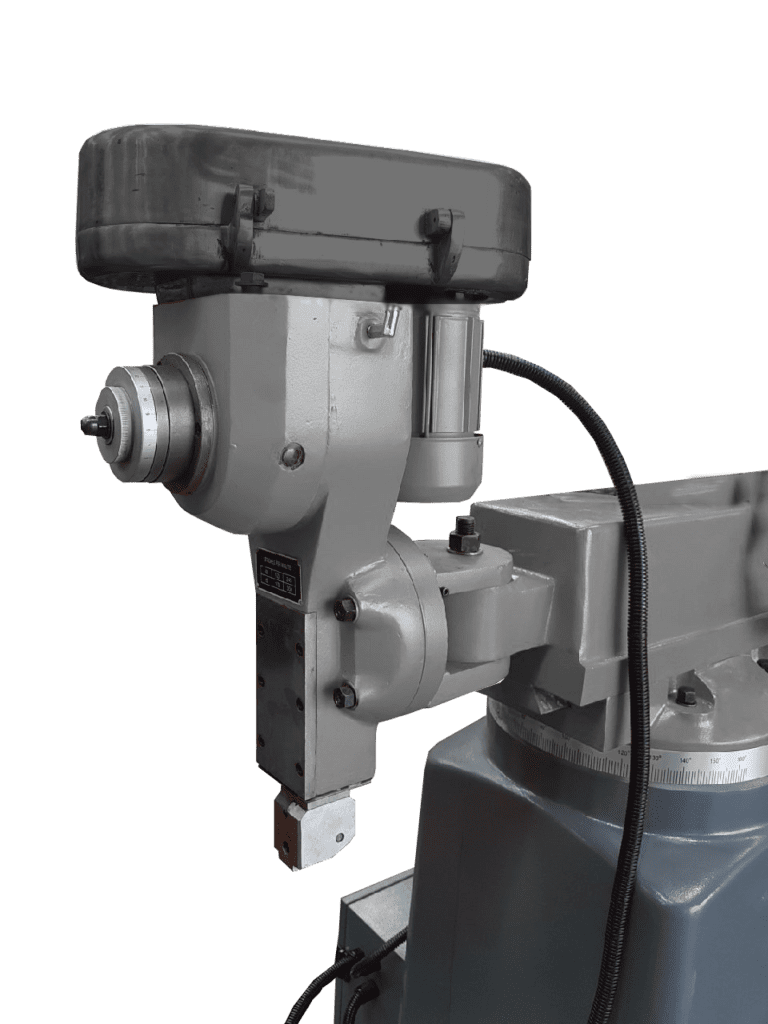

Meyer Turret Milling Machine 415V

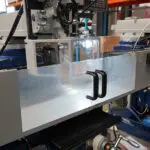

The Meyer Turret Milling Machine 415V are high precision, very accurate and extremely versatile turret milling machines. The turret head can be inclined upwards and downwards, rotated in both vertical and horizontal planes, clockwise and anticlockwise. Each angle can be finely set due to the degree scales for all three variations. X, Y and Z axis are easily and accurately controlled by both the hand wheels, with micrometer scales which can be zeroed, and the intuitive DRO system.

The 220RX model takes R8 tooling whilst the 375S and 560S models driven by powerful motors take ISO40 tooling. Belt driven variable power feed with fast override button is fitted as standard to the X axis on the 220RX models and to X, Y and Z axis on the 375S and 560S machines.

| MODEL | 220RX | 375S | 560S | |

| STOCK CODE | 24200 | 24201 | 24219 | |

| Spindle Taper | R8 | ISO40 | ISO40 | |

| Spindle Travel | 127 | 127 | 127 | |

| Number of Spindle Speeds | mm | Variable (Belt Driven) | Variable (Belt Driven) | Variable (Belt Driven) |

| Spindle Speed | rpm | 60 – 4200 | 60 – 3600 | 60 – 3600 |

| Quill Power Feed | mm/rev | 0.04/0.08/0.15 | 0.04/0.08/0.15 | 0.04/0.08/0.15 |

| Motor | KW | 2.2 | 3.75 | 5.63 |

| Longitudinal Travel – Long | mm | 950 | 950 | 1000 |

| Saddle Travel – Cross | mm | 380 | 400 | 360 |

| Knee Travel – Vertical | mm | 400 | 400 | 400 |

| Max Distance Spindle To Table | mm | 400 | 400 | 450 |

| Table Size | mm | 254 x 1370 | 254 x 1370 | 330 x 1500 |

| Head Movement Left/Right | 90°/90° | 90°/90° | 90°/90° | |

| Head Movement Up/Down | 45°/45° | 45°/45° | 45°/45° | |

| Length | mm | 1670 | 1670 | 2180 |

| Width | mm | 1700 | 1700 | 2050 |

| Height | mm | 2235 | 2235 | 2300 |

| Weight | Kg | 1280 | 1320 | 2300 |

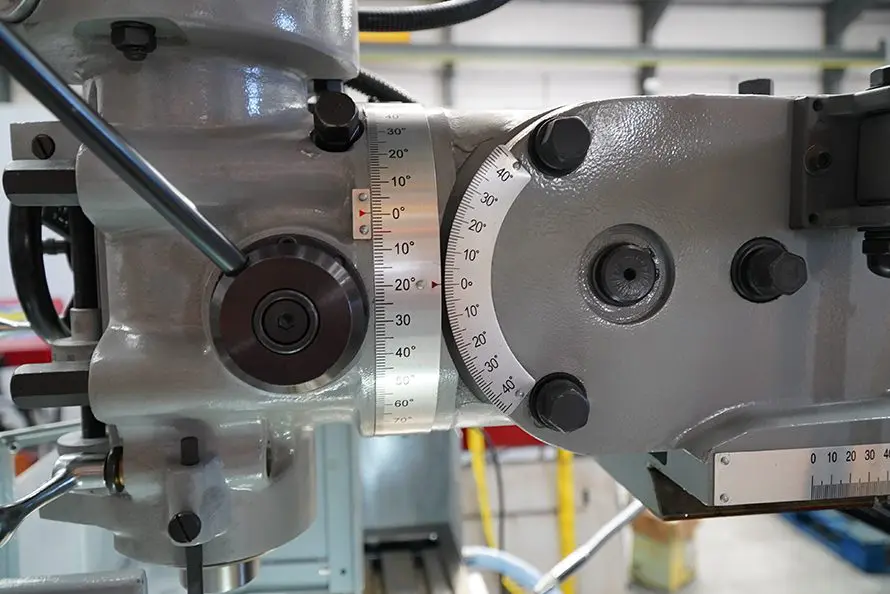

Slotting Head Attachment

| MODEL | SH-100 | SH-125 | |

| Max. Slotting Travel | mm | 100 | 125 |

| Min. number of strokes | RPM | 60 | 60 |

| Max. number of strokes | RPM | 350 | 350 |

| Main Spindle Speed Change | Stepped | 6 steps | 6 steps |

| Tool holder rotation angle | ° | 360 | 360 |

| Motor Power | W | 250 | 370 |

| Weight | Kg | 75 | 87 |

| Machine Dimension | mm | 450 x 300 x 700 | 450 x 300 800 |

Installation information

| MODEL | SH-100 | SH-125 |

| Fitted with T-Plug Indexation Circle | 150 mm | 150 mm |

| Tool holder rotation angle | 360° | 360° |

| Installation Mode | Vertical | Vertical |

| Fitted with T bolts | M12 x 80 | M12 x 80 |

Features

- High accuracy.

- Heavy duty.

- Hardened slideways.

- Centralised lubrication.

- DRO for X, Y and Z axis.

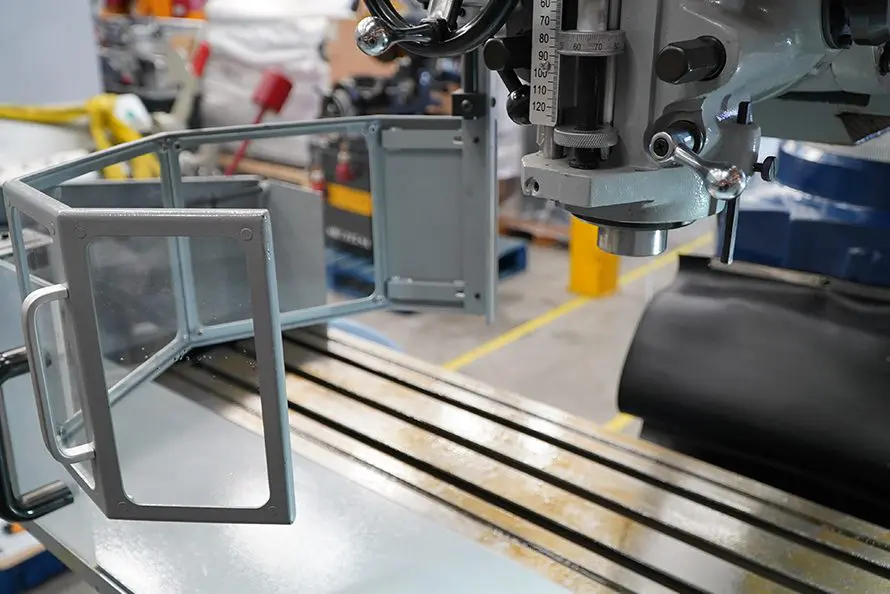

- Large table with T slots.

- Tapping facility.

- Motor brake lever.

- Coolant system.

- 220R/220RX – R8 tooling with power X axis.

- 375S/560S – ISO40 tooling with power X, Y and Z axis.

- Halogen lamp.

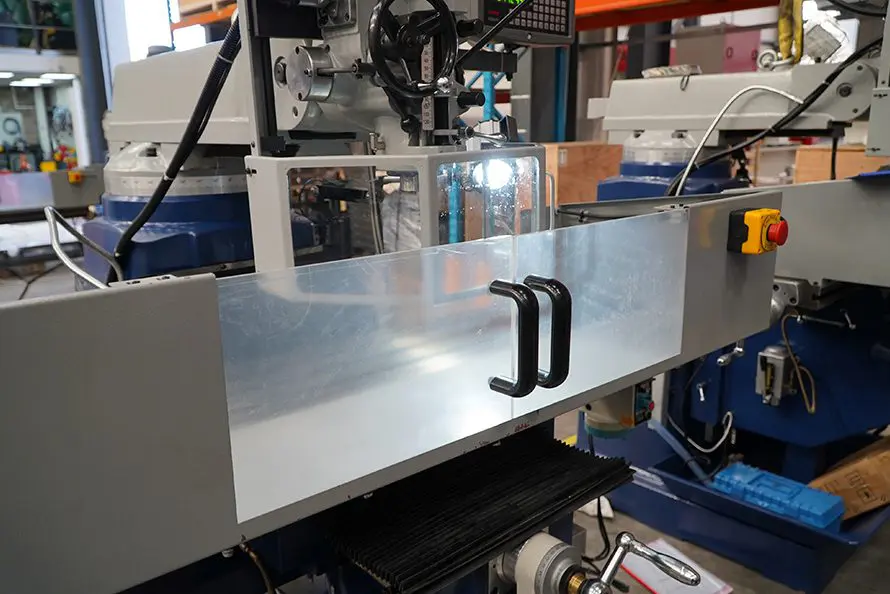

- Safety guard with interlock.

- Swarf Tray.

Options

- Powered X, Y and Z Axis (220RX)

- Inverter driven variable speed

- Slotting Head Attachment

Meyer Turret Milling Machine 415V

The Meyer Turret Milling Machine 415V is a high-precision, versatile, and accurate machine designed to meet the demands of modern machining tasks. Renowned for its flexibility and precision, the turret head can be adjusted in multiple planes: inclined upwards and downwards, rotated vertically and horizontally, and moved clockwise and anticlockwise. The degree scales for all three variations allow for fine adjustments, ensuring precise and repeatable settings. These capabilities make the Meyer Turret Milling Machine an indispensable tool for workshops requiring precision and adaptability.

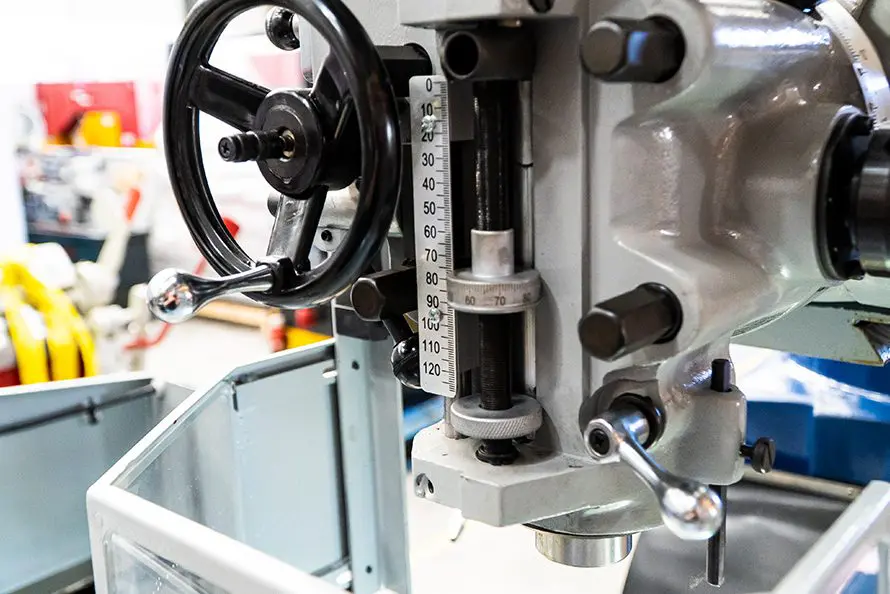

Precision and Control

The Meyer Turret Milling Machine features advanced control systems for the X, Y, and Z axes. Operators can use handwheels with micrometer scales that can be zeroed for manual adjustments. These scales ensure precise control, while the intuitive DRO (Digital Readout) system further enhances accuracy and ease of operation. This combination of manual and digital controls allows for a seamless machining experience, catering to both traditional and modern preferences.

Model Variants and Tooling Compatibility

The Meyer Turret Milling Machine is available in three distinct models to cater to varying operational needs:

- 220RX Model: Designed for precision tasks, this model is compatible with R8 tooling and features a belt-driven variable power feed on the X-axis. It is ideal for smaller workshops or tasks requiring high accuracy.

- 375S and 560S Models: Powered by robust motors, these models use ISO40 tooling, enabling them to handle more demanding machining tasks. Both models are equipped with belt-driven variable power feeds on the X, Y, and Z axes, providing greater versatility and efficiency.

Belt-Driven Variable Power Feed

One of the standout features of the Meyer Turret Milling Machine is its belt-driven variable power feed system. This system is standard across all models, with the 220RX offering it on the X-axis and the 375S and 560S extending it to all three axes. The power feed system enhances productivity by allowing smooth and consistent movement during machining operations. Additionally, a fast override button provides operators with immediate manual control when needed, ensuring precision and adaptability during critical tasks.

Versatility in Machining Applications

The Meyer Turret Milling Machine’s ability to adjust the turret head in multiple planes makes it suitable for a wide range of applications. From angled cuts and drilling to intricate milling tasks, the machine’s flexibility ensures it can handle complex geometries with ease. The combination of manual handwheels and DRO systems allows for detailed adjustments, making it ideal for industries such as automotive, aerospace, and general engineering.

Durable Construction and Reliable Performance

Built to last, the Meyer Turret Milling Machine features a sturdy and robust construction. This durability ensures consistent performance even in demanding industrial environments. The powerful motors on the 375S and 560S models provide the torque and reliability needed for heavy-duty tasks, while the precision-engineered components minimise maintenance requirements, making the machine a cost-effective investment for workshops.

Key Features of the Meyer Turret Milling Machine

- Adjustable Turret Head: Inclines and rotates in multiple planes for maximum flexibility.

- Micrometer Scales and DRO System: Ensures precise control of the X, Y, and Z axes.

- Tooling Compatibility: Supports R8 tooling (220RX) and ISO40 tooling (375S and 560S).

- Belt-Driven Variable Power Feed: Enhances productivity with smooth axis movement and manual override.

- Sturdy Construction: Designed for long-term reliability and performance.

- Powerful Motors: Robust performance on the 375S and 560S models for heavy-duty machining.

Applications Across Industries

The Meyer Turret Milling Machine is an invaluable asset across various industries. In automotive workshops, it excels at creating precision parts and components. Aerospace engineers benefit from its ability to handle intricate geometries and demanding materials. For general engineering applications, the machine’s versatility and reliability ensure consistent results for a wide range of tasks. Its adaptability and precision make it a preferred choice for professionals seeking high-quality machining solutions.

Conclusion

The Meyer Turret Milling Machine 415V combines precision, versatility, and reliability in a single package. With its adjustable turret head, advanced control systems, and powerful motors, it meets the needs of both small workshops and large industrial facilities. Whether you choose the 220RX, 375S, or 560S model, the Meyer Turret Milling Machine offers exceptional performance and value for a variety of machining applications. Invest in a Meyer Turret Milling Machine to enhance your workshop’s capabilities and achieve unparalleled results.