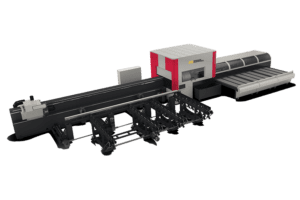

RVD Smart Fibre TFL Tube and Section Laser Cutting Machine

The RVD SmartFibre TFL range of tube laser cutting machines are especially applicable for round, square, rectangular, oval, waist round tubes and even beams.

Manufactured with the world’s leading fibre laser resonator and electronic components to ensure superior stability. The high clamping bed feature provides outstanding rigidity whilst performing at high speed and acceleration, taking your tube laser cutting to the next level.

| Stock Code | Unit | TFL |

|---|---|---|

| Laser Power | kW | 1.5 / 2 / 3 / 4 / 6 |

| Tube Loading / Unloading Length | mm | 12,000 |

| Tube Diameter | mm | Round Ø : 20 – 270 Square : 20 x 20 – 270 x 270 Beam: ≤ 270 x 270 |

| Cutting Profiles (Standard) | Round, Square, Rectangular | |

| Cutting Profiles (Optional) | Angle, Channel, H-Shape, L-Shape, Steel Band, etc | |

| Weight of Single Tube | kg | 300 |

| Positioning Speed | m/min | 90 |

| Chuck Rotation Speed | rpm | 100 |

| Axis Acceleration | G | 1 |

| Positioning Accuracy | mm | ±0.08 |

| Repeat Positioning Accuracy | mm | ±0.1 |

| Bevel | Deg | ±45° |

| Laser Power | kW | 1.5 | 2 | 3 | 4 | 6 |

| Cutting Capacity – Mild Steel | mm | 14 | 20 | 22 | 25 | 25 |

| Cutting Capacity – Stainless Steel | mm | 6 | 10 | 12 | 12 | 20 |

| Cutting Capacity – Aluminium | mm | 5 | 8 | 10 | 12 | 16 |

| Cutting Capacity – Brass | mm | 5 | 8 | 8 | 12 | 14 |

| Cutting Capacity – Copper | mm | 4 | 6 | 6 | 6 | 10 |

| Cutting Capacity – Galvanised Mild Steel | mm | 5 | 6 | 8 | 10 | 14 |

Features

- High performance Laser Source

- Fibre optic beam delivery system

- RayTools Autofocus Laser Cutting Head

- High strength, rigid gantry design to ensure high accuracy and allow high acceleration

- High precision class alpha rack and pinion drive motion system

- Applicable tube types : Round tube, square tube, rectangular tube, oval tube, D-shaped steel, T-shaped steel, H-shaped steel, channel steel, angle steel, etc.

- CE compliant complete machine enclosure and light barrier system

- Lantek Flex3d CNC Laser Control and Software

Options

- Outfeed Support – 12m

- Precitec ProCutter Head

- 3D Bevel Cutting Torch

- Optional Magazine Loading system

- Conveyor outfeed

- Weld Seam Detection

- UPS: Uninterruptible Power Supply

- Filtration & Extraction

RVD Smart Fibre TFL Tube & Section Laser Cutting Machine

Precision, Flexibility and Productivity for Modern Fabrication

The RVD Smart Fibre TFL is a next-generation CNC laser cutting system designed for high-performance tube, section and profile processing. Created for workshops that need speed, accuracy and versatility, the TFL series handles round tube, box section, angle, channel, beams and custom profiles with ease. Whether cutting mild steel, stainless, aluminium or non-ferrous materials, it delivers clean, consistent results with exceptional efficiency.

Key Features & Capabilities

Universal Profile Compatibility

The TFL is engineered for true multi-profile cutting. It processes round, square, rectangular, oval and flat-sided tubes as standard, with optional capability for open profiles including angle, channel, H-section, I-beam and custom extrusions. This makes it ideal for fabricators who handle a broad mix of structural components and need a single system to manage them all.

High-Performance Fibre Laser Technology

Available with fibre laser sources from 1.5 kW up to 6 kW, the machine delivers fast cutting speeds, smooth edges and tight tolerances across a broad range of materials. Higher-power configurations support thicker wall sections and increase productivity for demanding fabrication environments. The enclosed cutting area ensures a clean, safe and controlled process.

Robust Mechanical Design & Precision Motion

A rigid chassis, advanced motion control and precision rack-and-pinion or linear-guide systems ensure smooth, accurate positioning throughout the cut. Self-centring pneumatic chucks keep the workpiece stable, maintaining perfect alignment even on long profiles or heavy structural material. The result is reliable, repeatable accuracy for every part.

Automation & Smart Handling Options

Automation options such as bundle loading, magazine feeding, extended support rails and automatic unloading systems help maximise throughput while reducing manual handling. For advanced applications, optional 3D bevel-cutting allows chamfers, weld-prep edges and angled features to be cut in one process, reducing downstream finishing time.

Advanced CAD/CAM & Nesting Workflow

Supplied with professional tube-nesting and CAD/CAM software, the TFL system provides intuitive programming, accurate feature placement and efficient material utilisation. Multi-part nesting minimises waste and improves productivity, while seamless integration with the machine controller simplifies setup and accelerates production.

Safety, Compliance & UK-Ready Support

The fully enclosed cutting area, fume-extraction compatibility and CE-compliant safety systems make the TFL suitable for modern UK fabrication environments. Supported by Selmach’s installation, training and aftercare services, the machine is ready for immediate integration into your workflow.

Typical Applications

-

Structural steel fabrication

-

Box section, RHS/SHS and hollow-section production

-

Automotive, agricultural and industrial components

-

Staircases, balustrades, handrails and architectural metalwork

-

Chassis and tubular frameworks

-

High-volume manufacturing and batch production

-

Bespoke or precision metalwork requiring tight tolerances

Technical Summary

| Feature | Specification |

|---|---|

| Laser Power Options | 1.5 kW, 2 kW, 3 kW, 4 kW, 6 kW |

| Profile Capacity | Round tube 20–270 mm; Square/rectangular up to 270 × 270 mm |

| Standard Profiles | Round, square, rectangular, oval and flat-sided tubes |

| Optional Profiles | Angle, channel, H-section, I-beam, steel band and custom profiles |

| Maximum Tube Length | Up to 12,000 mm (loading/unloading) |

| Cutting Thickness (Material Dependent) | Thin- to thick-wall steels and alloys, depending on laser power |

| Positioning Accuracy | ±0.08 mm |

| Repeatability | ±0.1 mm |

| Optional Enhancements | 3D bevel cutting, bundle loading, magazine loader, outfeed conveyor, weld-seam detection, extraction, UPS and extended supports |

Why Choose the RVD Smart Fibre TFL?

The RVD Smart Fibre TFL isn’t just a tube laser — it’s a powerful, adaptable profiling system built to replace multiple machines and streamline your entire workflow. With its combination of cutting performance, automation, intelligent software and robust build quality, it enables fabricators to reduce labour, increase throughput and maintain exceptional accuracy across all profile types.

Supported by Selmach’s UK-wide engineering, installation and service network, the TFL series offers long-term reliability and a clear return on investment for fabrication shops of all sizes.