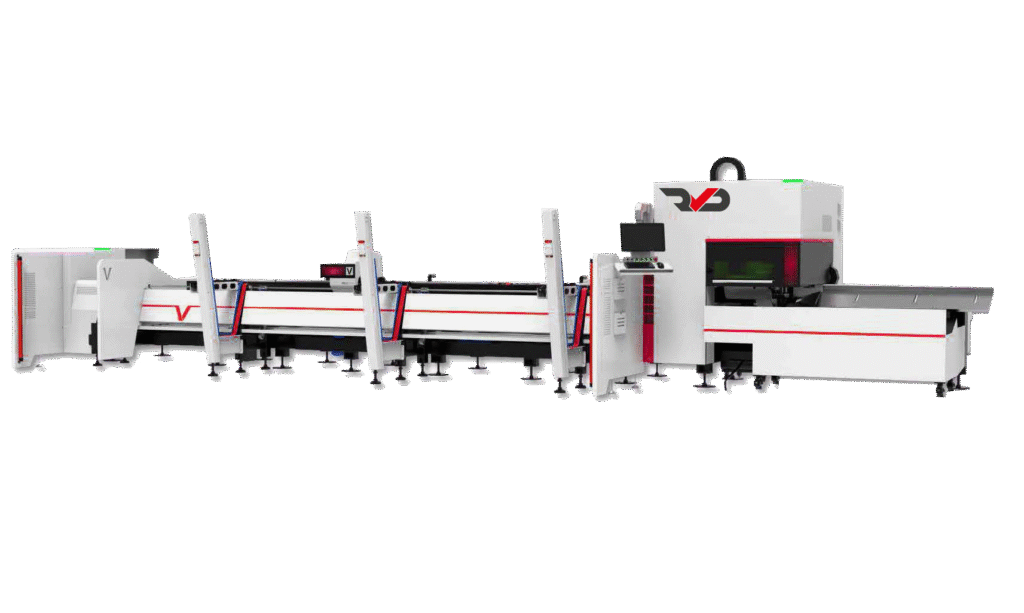

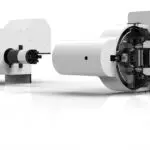

RVD Smart Fibre TFC Compact Tube Laser

The RVD TFC compact Tube Fibre laser tube cutting machine integrates intelligent, automated, and multi-functional modular designs. It supports ultra-fast automatic material feeding and offers flexible switching between fully automatic and semi-automatic modes, enabling efficient processing of tubes with diameters ranging from 8mm up to 160mm. The machine achieves three major breakthroughs: “zero scrap waste, multi-scenario compatibility, and high-precision ultra-fast production,” redefining the standards for ultra-mini-tube cutting.

It adopts a side-mounted machine bed structure, with the front chuck featuring a retractable function. When combined with a composite dual-function chuck, it enables zero scrap cutting, thereby minimising material waste. Additionally, it is equipped with a high-speed pneumatic chuck specially customised for small tubes. A full-servo floating support system is utilised at both the loading and unloading ends, working in tandem to enhance cutting accuracy and processing efficiency.

| TFC6312 | TFC6316 | ||

|---|---|---|---|

| Laser Power | kW | 1.5 – 6 | |

| Max. Tube Length | mm | 6,300 | |

| Tube Diameter | mm | Round: Ø8 – 120 Square: 8 x 8 – 120 x 120 | Round: Ø8 – 160 Square: 8 x 8 – 160 x 160 |

| Suitable for Cutting | Mild Steel, Stainless Steel, Galvanised Steel, Aluminium, Brass and Copper | ||

| Cutting Profiles | Round, Square, D-Shaped, Rectangular, Special Shaped, Angle, Triangular, Elliptical, Waisted Round, Channel, Strip and I-Beam | ||

| Weight of Single Tube | kg | 70 | |

| Positioning Speed | m/min | 120 | |

| Chuck Rotation Speed | rpm | 200 | |

| Axis Acceleration | G | 2.0 | |

| Positioning Accuracy | mm | 0.05 | |

| Repeat Positioning Accuracy | mm | 0.03 | |

| Laser Power | kW | 1.5 | 2 | 3 | 4 | 6 |

| Cutting Capacity – Mild Steel | mm | 14 | 20 | 22 | 25 | 25 |

| Cutting Capacity – Stainless Steel | mm | 6 | 10 | 12 | 12 | 20 |

| Cutting Capacity – Aluminium | mm | 5 | 8 | 10 | 12 | 16 |

| Cutting Capacity – Brass | mm | 5 | 8 | 8 | 12 | 14 |

| Cutting Capacity – Copper | mm | 4 | 6 | 6 | 6 | 10 |

| Cutting Capacity – Galvanised Mild Steel | mm | 5 | 6 | 8 | 10 | 14 |

Features

- High performance Raycus Laser Source

- Fibre optic beam delivery system

- BOCI BLT 310T Autofocus Laser Cutting Head

- High strength, rigid gantry design to ensure high accuracy and allow high acceleration

- German LEITESEN rack drive motion system

- Applicable tube types: Round tube, square tube, rectangular tube, oval tube, D-shaped steel, T-shaped steel, H-shaped steel, channel steel, angle steel, etc.

- Material Receiving and Collecting System

- CE compliant complete machine enclosure and light barrier system

- FSCUT3000DE Control System

- BOCHU TubePro Tube Cutting Software

- TubesT – Tube Nesting Software

- Semi-Automatic Loading System

- Zero scrap cutting with pneumatic clamping system to avoid final parts being stuck in the chuck

- Scrap collection drawer

Options

- 1.5 – 6 kW Laser Source

- Optional infeed lengths up to 8m

- Optional outfeed lengths up to 4m

- Optional bevel cutting head

RVD TFC Compact Tube Fibre Laser Cutting Machine

Intelligent, High-Speed, Zero-Scrap Tube Processing

Discover a new standard in precision tube cutting with the RVD TFC Compact Tube Fibre Laser Cutting Machine — engineered for efficiency, flexibility, and zero material waste. With advanced automation, high-speed performance, and intelligent control systems, the TFC redefines what’s possible in small tube processing.

Precision Tube Cutting with Zero Scrap Waste

The RVD TFC sets a new benchmark with its innovative zero-scrap design, made possible by a side-mounted machine bed and a retractable front chuck. Combined with a composite dual-function clamping system, this allows complete cutting of each tube — eliminating up to 220mm of typical scrap waste.

Its automatic avoidance program ensures seamless head movement between chucks, completing final cuts without interference. The result? Zero offcuts, higher material yield, and precise cutting right to the tube’s end.

Full Automation Meets Intelligent Flexibility

With support for fully automatic and semi-automatic modes, the TFC enables high-speed processing for a wide range of materials and profiles:

-

Tube diameters from Ø8mm to 120mm

-

Materials: Mild Steel, Stainless Steel, Aluminium, Brass, Copper, Galvanised Steel

-

Shapes: Round, Square, Rectangular, Oval, D-Shape, T-Shape, Channel, I-Beam, and more

The full-servo floating support system ensures smooth material handling and cutting precision at both the loading and unloading ends — ideal for delicate, thin-walled tubes.

High-Speed Performance That Delivers

Engineered for efficiency, the RVD TFC offers unmatched speed and control:

-

2.0G Maximum Acceleration

-

120m/min Positioning Speed

-

200rpm Chuck Rotation Speed

-

0.03mm Repeat Positioning Accuracy

These capabilities significantly reduce non-cutting time and improve productivity in demanding production environments.

Advanced Laser Cutting Technology

Featuring industry-leading components for reliability and performance:

-

Raycus Fibre Laser Source (1.5 – 6kW options)

-

BOCI BLT 310T Autofocus Cutting Head

-

BOCHU FSCUT3000DE Controller with TubePro Software

-

LEITESEN Rack & Pinion Drive

-

High-rigidity gantry structure for smooth, stable operation

The system is fully CE compliant, with a complete enclosure and safety light barriers for operator protection.

Dual Loading System for Seamless Tube Handling

Handle various batch sizes with the dual-mode loading system, combining:

-

Fully Automatic Bundle Loading

-

Semi-Automatic Single Tube Loading

This smart hybrid design allows continuous, unattended processing or operator-assisted control as needed — ideal for varying production volumes.

Intelligent Material Receiving and Discharge

Maximise throughput with a fully integrated discharging system:

-

Adaptive supports for variable-length tubes

-

Smooth, inclined slide for gentle unloading

-

Efficient storage and batch collection area

-

Reduced manual handling and increased automation

Every detail is designed to streamline your workflow and minimise downtime.

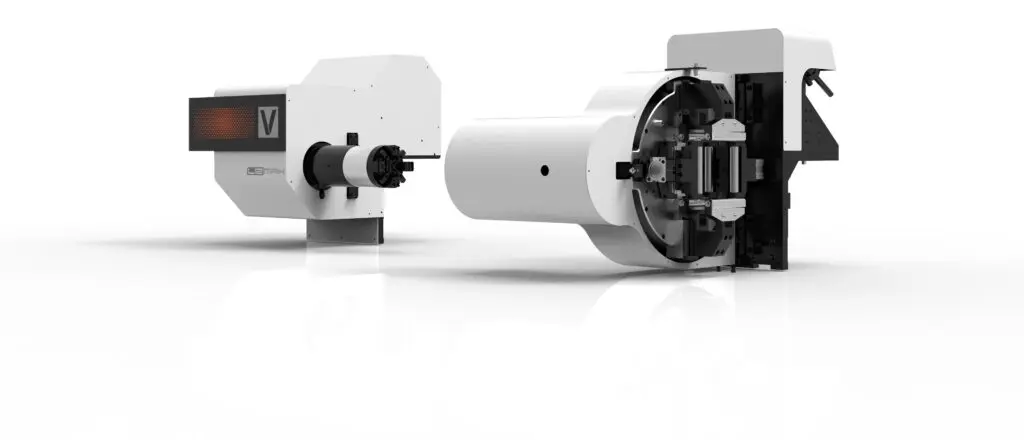

Built to Last – Durable, Dust-Sealed Chuck System

The TFC’s fully enclosed pneumatic chuck system offers:

-

High clamping force with visual adjustment

-

Anti-dust design to prevent jamming and wear

-

Wear-resistant components for extended life

This ensures optimal clamping stability and minimal maintenance — even in high-volume production environments.

Optional Upgrades

Enhance your system to meet specific application needs:

-

Up to 6kW laser source

-

Infeed lengths up to 8m

-

Outfeed lengths up to 4m

-

Optional bevel cutting head