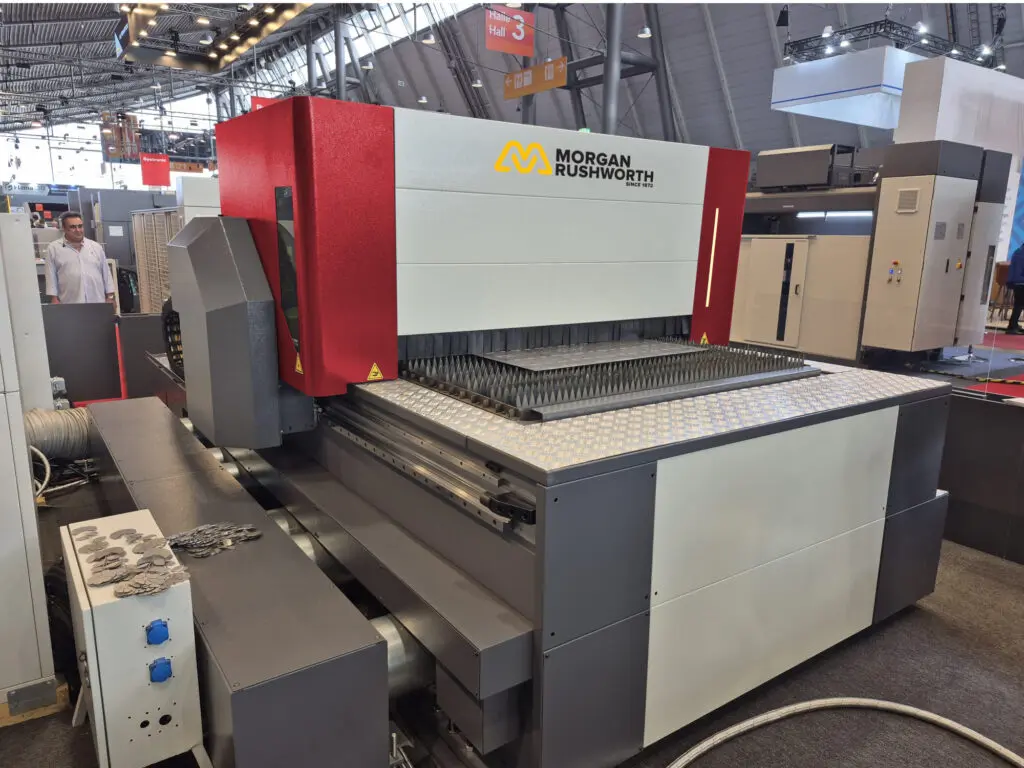

Morgan Rushworth XRM Fibre Laser Cutting Machines

Building on the impressive build quality of the XR series of Fibre Laser, the XRM is the next step in innovation for compact fibre laser. A single table with a moving cabin ensures that you take up a minimal footprint in your workshop, without sacrificing machine build quality, or cutting finish. Class leading components ensure superior cut quality, high reliability and reduced down time.

The range covers from 3kw up to 12kw which with the high performance rack and pinion system for X & Y axis and rigid gantry and frame structure, results in fast acceleration, fast positioning speeds and fast cutting times. A user friendly touch screen CNC control allows parts to be programmed on the screen or imported from an office PC, providing flexible modes of operation.

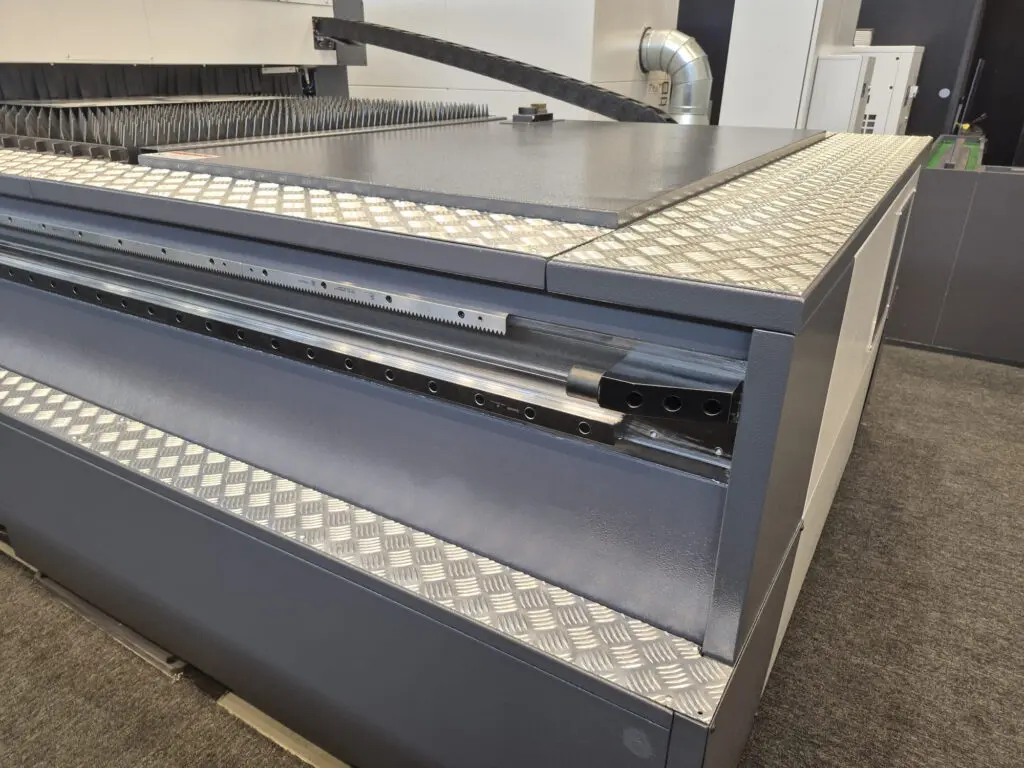

The cabin section moves along a heavy-duty rack and pinion system, and opens up after cutting for easier parts removal and material loading. The cabin provides full CE safety protection for operators while keeping down costs.

| Stock Code | XRM 3015 |

|---|---|

| Fibre Laser Source | 3 – 6 kW |

| X Axis Travel | 3048 mm |

| Y Axis Travel | 1524 mm |

| Z Axis Travel | 100 mm |

| Maximum Sheet Size | 3000 × 1500 mm |

| Positioning Speed | 65 m/min |

| Acceleration | 0.6 G |

| Maximum Table Capacity | 900 kg |

| Positioning Accuracy | 0.05 mm |

| Length | 5100 mm |

| Width | 2400 mm |

| Height | 2100 mm |

| Weight | 9000 kg |

Features

- Fibre laser source available from 3Kw – 12Kw

- Raytools or Precitec Procutter cutting head with auto focus and anti-collision functionality (kW dependent)

- Servo motors and drives

- Heavy Duty rack and pinion system with automatic lubrication

- SMC automatic gas selection system

- 19” touch screen controller with part graphic view and extensive cutting parameter data base

- Beckhoff CNC controller, servo motors and drives – increases acceleration and positioning speed

- Automatic sheet edge detection with skew allowance

- Automatic nozzle cleaning and calibration

- Class leading Lantek software

- Moving Laser Cutting Cabin, with hinge mechanism

- Side Window viewing areas with laser protective material

- Light guard protection for cutting table

- Pull out Parts / Scrap Bins

- CCTV view of cutting action

Options

- Fume extractor with filters

- Air compressor and dryer

High-precision, compact footprint fibre laser cutting for heavy-duty production

Stock Code: XRM 3015 (other variants available)

Laser Source Range: 3 kW – 12 kW

Maximum Sheet Size: 3000 × 1500 mm (for the XRM 3015)

Why choose the Morgan Rushworth XRM?

When you’re investing in a fibre-laser cutting solution for precision metal fabrication, productivity, and workshop efficiency, the Morgan Rushworth XRM series delivers. Designed with a moving cabin and single-table layout, this system minimises floor space while maximising rigidity and cutting performance.

Its heavy-duty gantry and rack-and-pinion drive system ensure high acceleration and fast positioning, enabling short lead times and superior cut finish. Built by Morgan Rushworth (a trusted UK engineering brand), the XRM brings together reliability, technology and practicality.

Key Features & Benefits

-

Fibre-laser source from 3 kW up to 12 kW, allowing you to scale power according to material thickness and application demands.

-

Raytools or Precitec Procutter head (depending on power option) with autofocus and anti-collision for automated, high-quality cutting.

-

Heavy-duty rack and pinion drive system for X & Y axes – automatic lubrication for reduced maintenance.

-

High-speed servo motors & drives — enabling superior positioning speeds and acceleration (ideal for high-volume or multi-part production).

-

19-inch touch screen controller with graphic display and extensive parameter database, plus full import of CAD/Nesting data from office PC.

-

Fully enclosed moving cabin with hinged access, improving operator safety (CE-compliant) and facilitating material loading/unloading.

-

Automatic sheet-edge detection and skew allowance – maximises sheet utilisation and minimises waste.

-

Pull-out parts & scrap bins, CCTV view of cutting action, and protective side windows – all designed for operational efficiency and safety.

-

Compatible with industry-leading nesting and ERP software (e.g., Lantek) to integrate into your production workflows.

Technical Specification (XRM 3015)

| Parameter | Value |

|---|---|

| Stock Code | XRM 3015 |

| Fibre Laser Source | 3 – 6 kW |

| X Axis Travel | 3048 mm |

| Y Axis Travel | 1524 mm |

| Z Axis Travel | 100 mm |

| Maximum Sheet Size | 3000 × 1500 mm |

| Positioning Speed | 65 m/min |

| Acceleration | 0.6 G |

| Maximum Table Capacity | 900 kg |

| Positioning Accuracy | 0.05 mm |

| Length | 5100 mm |

| Width | 2400 mm |

| Height | 2100 mm |

| Weight | 9000 kg |

Applications & Industry Use

The XRM series is well suited for fabricators, sheet-metal workshops and contract manufacturers who work on structural steel, mild steel, stainless steel and aluminium. Whether you are producing architectural panels, bespoke metal components, enclosures or high-volume parts, the compact footprint and high-precision make the XRM an ideal choice for modern fabrication.

With its ability to switch between high production runs and short batch jobs (thanks to the fast drive system and intuitive control), it fits well in flexible manufacturing environments where turnaround time, quality and cost-control matter.

Machine Footprint & Workshop Integration

Thanks to the moving cabin design and single-table concept, the XRM minimises required floor space compared with older laser systems. The machine length of 5100 mm and width of 2400 mm means you can plan around it effectively. The height of 2100 mm ensures appropriate clearance and ease of access for maintenance and operations.

We recommend allowing additional clearance around the machine for material loading/unloading, part removal, and maintenance access. Also plan for appropriate fume extraction, electrical supply and service access.

Options & Upgrades

To tailor the machine to your production needs, the following options are available:

-

Fume extractor with high-efficiency filters

-

Air compressor & dryer package

Why Buy from Selmach Machinery Ltd?

As the UK’s leading specialist supplier of metalworking machinery, we at Selmach Machinery Ltd bring deep industry experience, service, and parts support. Our focus on service, efficiency and quality means we don’t just sell machines — we help you integrate them into your workflow, reduce downtime, and worry less about after-sales.

We know how critical it is that machinery performs day-in, day-out, and we stand behind the Morgan Rushworth brand with UK-wide support.