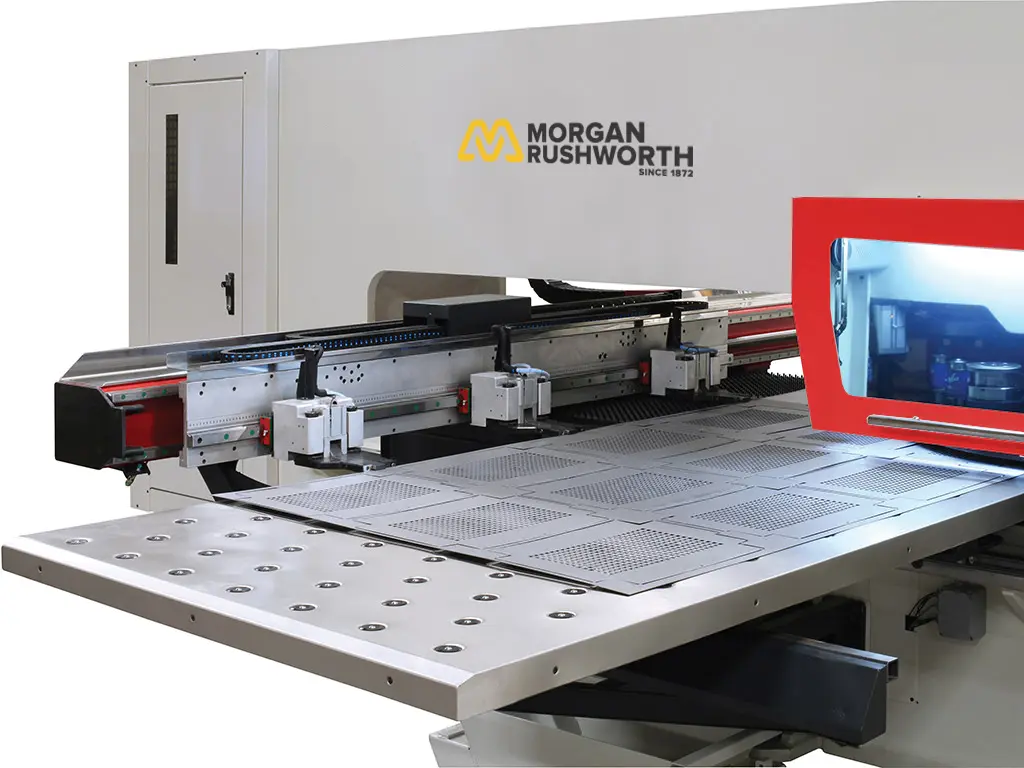

Morgan Rushworth TPM CNC Turret Punch Press

The Morgan Rushworth TPM CNC Turret Punch Press features an extremely rigid ‘O’ frame design tested by Finite Element Analysis so that there is minimum deflection in the machine body even under maximum load and ensuring high precision performance.

The machines are designed for high production with up to 1G acceleration when positioning and a maximum speed of 900 strokes per minute when nibbling at 1mm pitch. The 12 station turret features 3 indexable stations as standard which can be fitted with either 3 or 8 station multi tools.

| STOCK CODE | TPM 2515 | |

|---|---|---|

| Punching Force | Tonnes | 30 |

| Total Number of Tool Stations | 12 | |

| No. of Indexable Tool Stations | 3 | |

| Tool Change Time – Multi Tools | sec | 1 |

| Tool Change Time – Turret | sec | 3 |

| CNC Controlled Axes | X, Y, Z, C1, C2, T | |

| C1 & C2 Axes Drive Type | Direct Drive | |

| Working Area (X & Y) | mm | 2,540 x 1,540 |

| Z Axis Stroke | mm | 30 |

| X Axis Repositioning | Yes | |

| X Axis Speed | m/min | 100 |

| Y Axis Speed | m/min | 80 |

| X & Y Axis Combined Speed | m/min | 128 |

| C1 & C2 Rotational Speed | RPM | 100 |

| T Rotational Speed | RPM | 30 |

| Nibbling Rate – 1mm Pitch | strokes/min | 900 |

| Nibbling Rate – 25mm Pitch | strokes/min | 580 |

| Maximum Sheet Weight | kg | 170 |

| Maximum Sheet Thickness | mm | 6.4 |

| Punching Accuracy | mm | ± 0.1 |

| Repeatability | mm | ± 0.04 |

| Maximum Punching Diameter (for 6.4mm Thickness) | mm | 25 |

| Number of Material Clamps | 3 | |

| Working Height of Table | mm | 980 |

| Oil Tank Capacity | litre | 300 |

| Motor Power | kW | 11 |

| Length | mm | 6,060 |

| Width | mm | 5,210 |

| Height | mm | 2,220 |

| Weight | kg | 14,000 |

Features

- Extremely rigid ‘O’ Frame design

- High strength, centrally driven beam fitted with three sheet clamps providing up to 1G acceleration

- Heavy duty and precise sheet clamps with sliding system to prevent sheet jamming.

- High quality ball bearings and linear guides allow extremely precise positioning as well as high speed movement

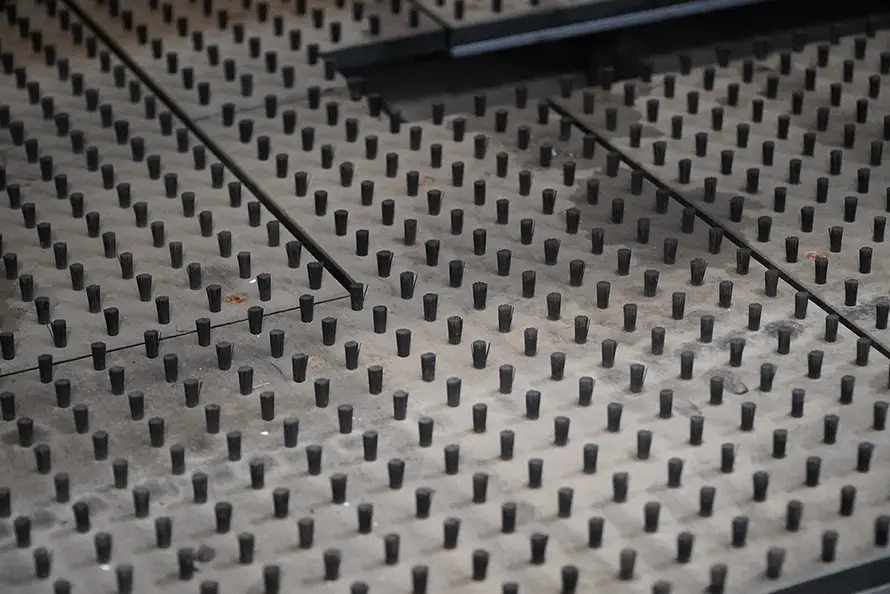

- Ball transfer and brush table combination

- Moveable table system in Y axis ensuring the material is supported at the edges and reducing vibrations

- 12 station turret including 3 indexable stations (one each of B, C and D stations)

- Capable of producing not only 2D components but when fitted with special tools can create 3D forms up to 8mm deep in 1mm material

- Patented Direct Drive index mechanism.

- Low energy hydraulic system with low and high pressure hydraulic pumps. Energy savings of up to 50% are achievable.

- CE compliant light barrier system

- Ergonomic free standing CNC control console with 15” TFT

- Bosch MTX CNC Control System

- Lantek Nesting Software

- Turret configuration module within the Lantek software allows the editing of the turret layout

Options

- Vacuum System for Scrap Removal

- Scrap Conveyor

- Indexable Multi Tools

- Additional license for Lantek CAM Software

- Single punching tools and special forming tools

- Special coated tools for stainless steel

The Morgan Rushworth TPM CNC Turret Punch Press is a high-performance sheet metal punching solution designed for precision, speed and long-term reliability in demanding fabrication environments. Built around an extremely rigid ‘O’ frame structure and optimised using Finite Element Analysis (FEA), the TPM delivers consistent punching accuracy even under maximum working load. Minimal frame deflection means tighter tolerances, longer tooling life and dependable repeatability shift after shift.

Designed for serious production output, the TPM achieves positioning acceleration of up to 1G and nibbling speeds of up to 900 strokes per minute at 1mm pitch, making it suitable for both high-volume component manufacture and flexible batch production.

High Rigidity Frame – Built for Precision

The heart of the machine is its heavy duty O-frame construction. Unlike lighter C-frame machines, this design distributes punching forces evenly through the structure, reducing vibration and maintaining alignment between punch and die.

A centrally driven high-strength beam combined with three precision sheet clamps ensures stable sheet movement at speed. The sliding clamp system prevents material snagging during repositioning while maintaining consistent sheet control across the working area.

High-quality ball bearings and linear guideways allow smooth high-speed motion while maintaining positioning accuracy of ±0.1mm and repeatability of ±0.04mm.

The moveable Y-axis table supports material close to the working edge, reducing flex and vibration during punching and forming operations — particularly important when processing larger sheets or thin materials.

Fast Production Performance

The TPM is engineered for throughput. Rapid axis speeds and a direct drive indexing system allow the machine to maintain accuracy even during complex tool rotations and high speed repositioning.

With a combined X-Y speed of 128m/min, and fast tool change times, the machine minimises idle time between operations.

The 12-station turret includes three indexable stations (B, C and D) as standard. These can be fitted with multi-tools, allowing several punch geometries to be available without turret rotation — dramatically reducing cycle time.

Key production capabilities include:

-

Up to 900 strokes/min nibbling at 1mm pitch

-

Direct drive indexable tool rotation

-

Multi-tool compatibility (3 or 8 station)

-

Automatic repositioning in X axis

-

Fast turret indexing and 1 second multi-tool change

The machine is also capable of producing 3D forms up to 8mm deep in 1mm material using special forming tools, enabling louvres, embossing and forming features without secondary operations.

Advanced CNC Control & Software Integration

The TPM is equipped with a Bosch MTX CNC Control System mounted on an ergonomic free-standing console with a 15” TFT display, providing intuitive machine operation and clear program monitoring.

For programming and nesting, the machine is supplied with Lantek CAM software, allowing efficient sheet utilisation and fast program generation. The turret configuration module allows operators to edit turret layouts digitally, simplifying tool management and setup.

Benefits include:

-

Reduced material waste through optimised nesting

-

Faster program creation

-

Simple tool configuration editing

-

Seamless CAD/CAM workflow integration

Energy Efficient Hydraulic System

The hydraulic punching system uses dual pressure pumps, automatically switching between high and low pressure depending on punching demand. This intelligent energy management system can deliver up to 50% energy savings compared to conventional hydraulic turret punch presses.

The result is lower running costs, reduced heat generation and improved oil life.

Material Handling & Sheet Stability

The machine features a ball transfer and brush table combination to support sheets while preventing scratching of finished surfaces. Three heavy duty clamps securely hold material up to 170kg sheet weight while maintaining precise positioning during high speed movement.

Optional automation features such as scrap conveyors and vacuum removal systems allow continuous production with minimal operator intervention.

Safety & Operator Environment

Operator safety is ensured through a CE compliant light barrier system protecting the working area while allowing fast material handling. The working table height of 980mm provides comfortable loading and unloading.

The separate control console improves visibility and ergonomics, reducing operator fatigue during long production runs.

Optional Equipment

The TPM can be configured to suit different production requirements with options including:

-

Vacuum scrap removal system

-

Scrap conveyor

-

Indexable multi-tools

-

Additional Lantek CAM licenses

-

Special forming tools

-

Stainless steel coated tooling

Built for Modern Fabrication

The Morgan Rushworth TPM is suited to subcontractors, OEM manufacturers and fabrication workshops requiring consistent precision across high production volumes. By combining rigid mechanics, intelligent hydraulics and advanced CAM integration, the machine reduces setup time, lowers operating costs and improves throughput.

In practical workshop terms: fewer secondary operations, less manual handling and more finished parts per shift.

A turret punch press is often the quiet productivity engine of a fabrication shop; not flashy like a laser, but terrifyingly efficient once properly fed with work. The TPM leans fully into that philosophy: repeatable, predictable and optimised for output rather than drama.