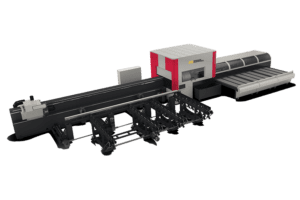

Morgan Rushworth SPM CNC Tube & Section Plasma Machine

The Morgan Rushworth SPM Tube Plasma profiling system is a highly innovative machine combining the low-cost benefits of mechanised air plasma cutting with CNC automation and nesting. With the ability to profile up to 300mm diameter round tube at 12 metres long, the SPM has the capability for most common tube working requirements. Combined with the durable and recognised Hypertherm Powermax system, the SPM automates many manual processes into one seamless CNC designed and controlled cutting operation.

| MODEL | SPM 150 | SPM 220 | SPM 300 | |

| Round Tube | mm | 150 | 220 | 300 |

| Square Tube | mm | 100 | 150 | 200 |

| Maximum Part Weight | kg | 150 | 250 | 500 |

| Maximum Feed | mm/sec | 125 | 250 | 250 |

| Part length up to | m | 3, 6 or 9 | 3, 6, 9 or 12 | 6, 9 or 12 |

| Drive | Servo stepper | Servo synchronous motor | Servo synchronous motor | |

| Gear / rack | Hardened and ground | Hardened and ground | Hardened and ground | |

| Loading | Manual | manual | manual | |

| Front gate drive | x | optional | optional | |

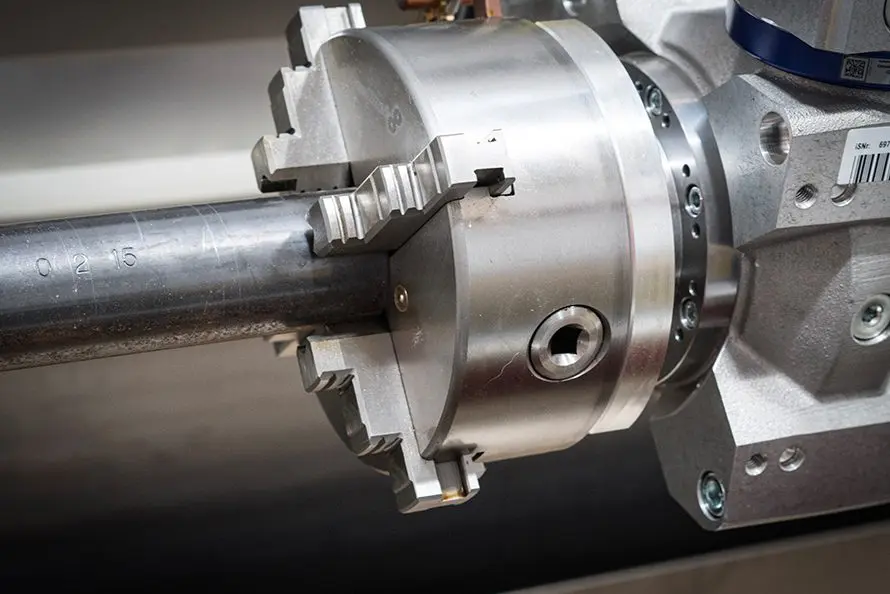

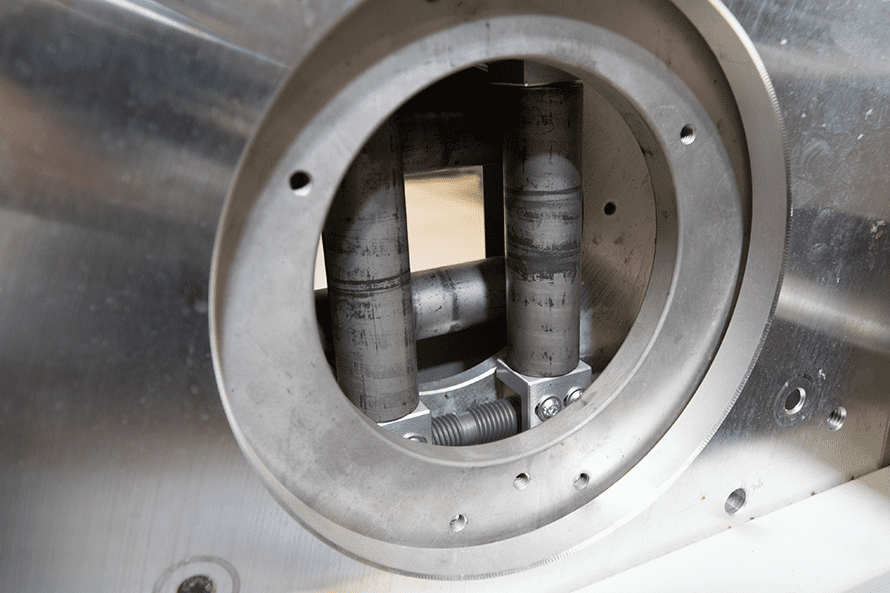

| 4 jaws Chuck | mm | 160 | 200 | 250 |

| Control System | 12″ B&R Industrial PLC | 12″ B&R Industrial PLC | 12″ B&R Industrial PLC |

Features

- Multi part nesting on a bar for optimised material usage

- Removes many traditional manual functions – sawing, cropping, grinding, notching, punching, drilling etc

- CNC accuracy; No errors or need to rework

- Tube Plasma cutting capability up to 12m length x 300mm diameter

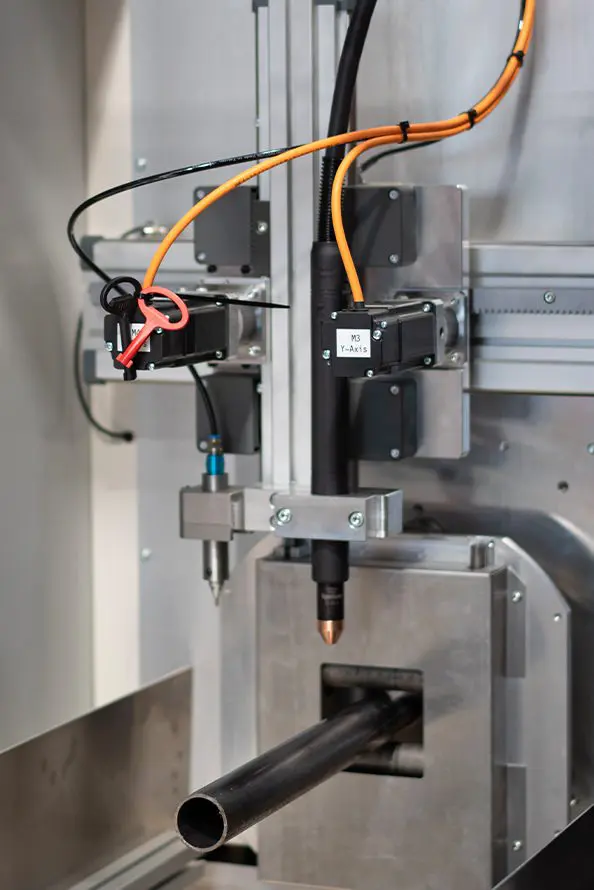

- Hypertherm Powermax Plasma Source 45a – 105a

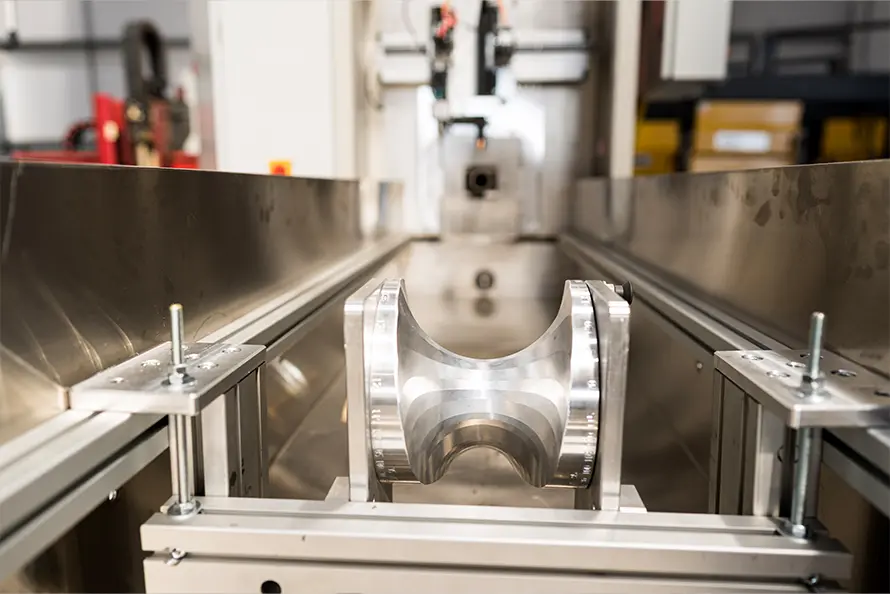

- Automated 4 Jaw Chuck Clamp & Feed carriage assembly from 3 to 12 metres

- Linear motion & rack & pinion movement

- Fully automated cutting process

- Centralising through-feed chuck at cutting station

- 12″ Touchscreen CNC Control allowing import and storage of cut files plus design of cut parts on the control

- Fully CE protected operation cabin using Light beams

- Engraving & Marking features available

- Automatic Torch height control

- Automatic Pipe Support on infeed

- Data import by USB & network

Options

- Marking

- Water Flush

- Support Roller – Outfeed

Morgan Rushworth SPM CNC Tube & Section Plasma Machine

The Morgan Rushworth SPM Tube Plasma Profiling System represents a groundbreaking advancement in tube and section profiling. This innovative machine combines the cost-effective benefits of mechanised air plasma cutting with the precision and efficiency of CNC automation and nesting. Designed to streamline operations and enhance productivity, the SPM is an ideal solution for businesses requiring high-quality tube profiling.

Exceptional Profiling Capabilities

The Morgan Rushworth SPM is engineered to handle a wide range of tube and section profiling tasks with ease. With the ability to profile round tubes up to 300mm in diameter and lengths of up to 12 metres, the machine is versatile enough to meet most common tube working requirements. Key profiling capabilities include:

- Cutting precision: Achieve clean, accurate profiles with minimal waste.

- Material versatility: Handles a variety of tube materials, including mild steel, stainless steel, and aluminium.

- Complex shapes: Capable of cutting intricate profiles, openings, and end preparations for weld-ready components.

Hypertherm Powermax Technology

At the core of the SPM’s cutting performance is the Hypertherm Powermax system, a highly durable and reliable plasma power source. Renowned for its performance and longevity, the Powermax system offers:

- High-quality cuts: Ensures smooth, dross-free edges, reducing the need for post-processing.

- Efficient operation: Minimises consumable usage and gas costs, resulting in lower operating expenses.

- Consistent reliability: With a robust design, the Powermax system provides dependable performance even under demanding conditions.

This integration of Hypertherm technology ensures that the SPM delivers industry-leading results, making it a valuable asset for any tube profiling operation.

CNC Automation and Nesting

The SPM is equipped with a CNC automation system that simplifies tube profiling and optimises material usage. Key features include:

- Automated processes: Reduces manual intervention, saving time and labour costs.

- Nesting capabilities: Optimises material layout to minimise waste and maximise productivity.

- User-friendly interface: Simplifies operation, reducing training requirements and increasing efficiency.

With these advanced features, the SPM transforms tube profiling into a seamless and efficient operation, enabling businesses to increase throughput and reduce costs.

Durable and Reliable Design

The Morgan Rushworth SPM is built to withstand the rigours of demanding workshop environments. Its robust construction ensures long-term reliability and consistent performance. Key design elements include:

- Heavy-duty frame: Provides stability and precision during operation.

- High-quality components: Reduces maintenance requirements and prolongs the machine’s lifespan.

- Compact footprint: Maximises workshop space while offering a large working capacity.

This durable design ensures that the SPM is a dependable solution for businesses of all sizes, from small workshops to large manufacturing facilities.

Applications Across Industries

The versatility of the SPM makes it suitable for a wide range of industries, including:

- Fabrication and manufacturing: For producing custom components and assemblies.

- Construction: Cutting structural tubes and sections for building frameworks.

- Automotive: Profiling tubes for exhaust systems, chassis components, and more.

- Marine: Creating profiles for shipbuilding and offshore applications.

By catering to diverse industry needs, the SPM offers unparalleled flexibility and adaptability.

Cost Efficiency and Productivity

The SPM’s combination of CNC automation, nesting, and Hypertherm technology results in significant cost savings and productivity gains. Benefits include:

- Reduced labour costs: Automation eliminates many manual processes, freeing up operators for other tasks.

- Material savings: Optimised nesting reduces waste, maximising material usage.

- Increased throughput: Faster cutting speeds and efficient operation boost productivity.

These advantages ensure a strong return on investment, making the SPM a cost-effective choice for businesses aiming to improve their tube profiling capabilities.

Optional Features and Upgrades

To meet specific operational needs, the SPM offers a range of optional features and upgrades, including:

- Integrated dust extraction systems: Maintain a clean and safe working environment.

- Bevel cutting attachments: Enable the creation of angled edges for specialised applications.

- Customised configurations: Tailor the machine to suit unique production requirements.

These options allow businesses to customise the SPM to meet their precise needs, enhancing its functionality and value.

Conclusion

The Morgan Rushworth SPM CNC Tube & Section Plasma Machine is a state-of-the-art solution for businesses seeking to enhance their tube profiling operations. With its innovative combination of mechanised air plasma cutting, CNC automation, and advanced nesting capabilities, the SPM delivers precision, efficiency, and cost savings. Its robust design and versatile applications make it a valuable investment for a wide range of industries.

By choosing the Morgan Rushworth SPM, businesses can streamline their operations, improve productivity, and achieve superior results. Invest in the SPM today to experience the future of tube profiling technology.