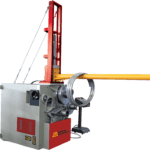

Morgan Rushworth HSR-3 Hydraulic Ring Rolling Machine 415v

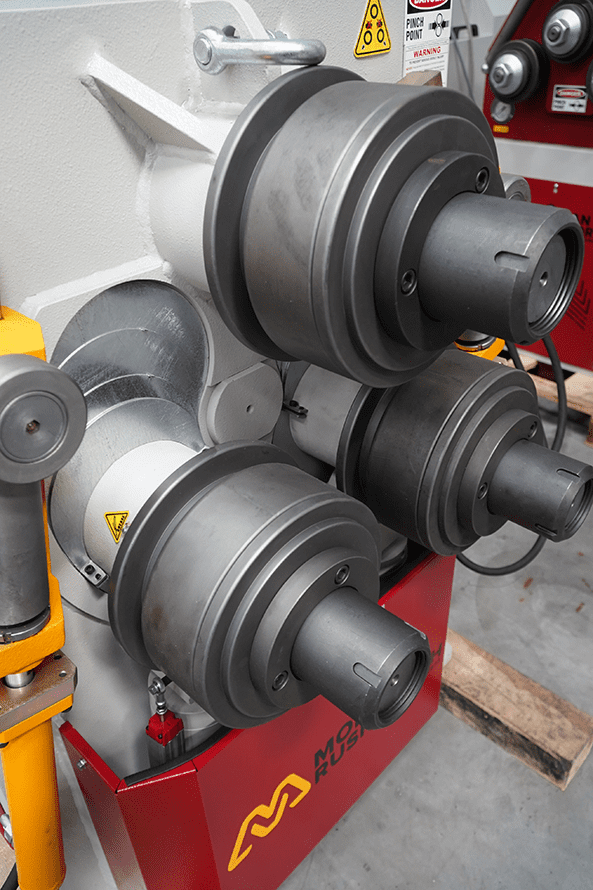

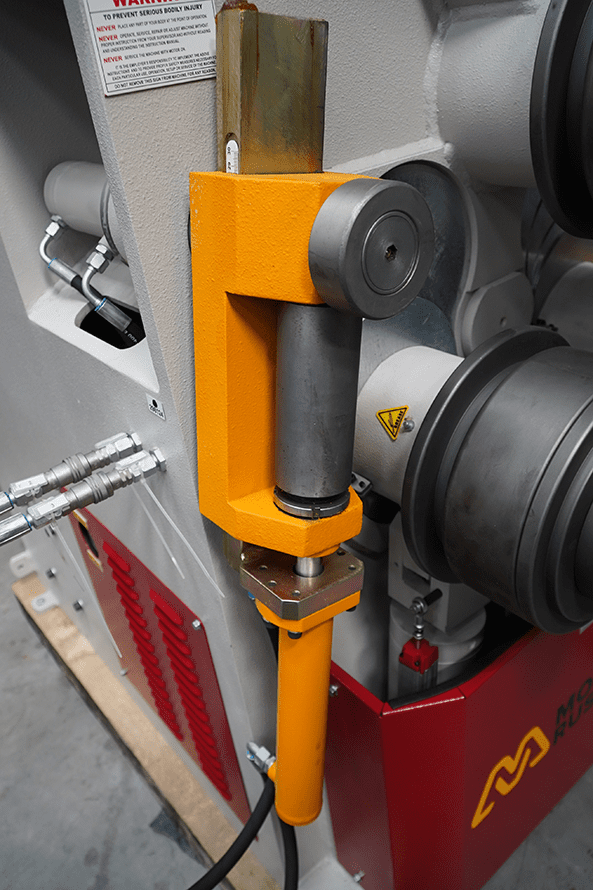

The Morgan Rushworth HSR-3 hydraulic section bending machines are designed to handle various material sections with shaft diameters from 40mm to 120mm. Twin hydraulic rams enable precise pre-bending and allow operations in the horizontal position for greater efficiency.

These versatile machines can be operated in both vertical and horizontal planes, catering to diverse bending tasks. Hardened standard rolls handle most sections, with optional tools available for round tubes. Adjustable lateral guide rolls ensure accurate bending or controlled spiraling, making the HSR-3 range an ideal choice for precision and versatility.

| MODEL | HSR-3 40/140 | HSR-3 60/180 | HSR-3 80/245 | HSR-3 100/315 | HSR-3 120/390 | HSR-3 160/480 | HSR-3 180/550 | HS-3 200/580 | HSR-3 240/620 | HSR-3 300/760 | HSR-3 360/800 | |

| Shaft diameter | mm | 35 | 60 | 80 | 100 | 120 | 160 | 180 | 200 | 240 | 300 | 360 |

| Roll diameter | mm | 137 | 180 | 245 | 315 | 390 | 480 | 550 | 580 | 620 | 760 | 800 |

| Rolling speed | m/min | 7 | 5 | 6 | 7 | 2 – 7.5 | 3 – 6 | 3 – 6 | 2 – 5 | 2 – 4 | 2 – 4 | 2 – 4 |

| Power | kW | 1.1 | 3 | 4 | 7.5 | 15 | 22 | 30 | 30 | 47 | 73 | 77 |

| Length | mm | 1,050 | 1,200 | 1,450 | 2,000 | 2,000 | 2,500 | 2,760 | 3,000 | 3,100 | 5,000 | 5,000 |

| Width | mm | 500 | 850 | 1,000 | 1,450 | 1,650 | 2,200 | 2,310 | 2,310 | 2,400 | 4,250 | 4,250 |

| Height | mm | 1,250 | 1,200 | 1,400 | 1,700 | 1,900 | 2,300 | 2,680 | 3,100 | 3,200 | 3,750 | 3,750 |

| Weight | kg | 350 | 1,000 | 1,700 | 3,650 | 4,450 | 9,300 | 14,400 | 16,500 | 19,800 | 38,500 | 55,100 |

For bending capacities, see our capacities chart

Features

- All three rolls driven for excellent traction

- Smooth rolls ensure minimum material marking

- Hardened rolls

- Movable control panel

- Digital read out indicating both lower roll position

- Overload protection device

- Hydraulically adjusted lateral guide rolls in 2 axis

- Hydraulically powered rotation

Options

- Tube rolls

- Variable speed of rotation

- Spiral bending device

- NC control system

- CNC control system

Morgan Rushworth HSR-3 Hydraulic Section Bending Machines: Precision and Versatility

The Morgan Rushworth HSR-3 range of hydraulic section bending machines is a testament to advanced engineering and adaptability, providing high-performance solutions for bending a wide variety of material sections. Designed with flexibility and precision in mind, these machines are available with shaft diameters ranging from 40mm to 120mm, ensuring compatibility with a diverse range of applications. Equipped with twin hydraulic rams to position the lower rolls, the HSR-3 series offers pre-bending capabilities, delivering clean and high-quality bends with minimal flat sections. Additionally, these machines allow operators to perform bending operations in the horizontal position, making them an efficient and practical choice for various workshop layouts.

A key feature of the HSR-3 series is its ability to operate in both vertical and horizontal planes. This dual capability provides unmatched versatility, making the machines suitable for a wide range of bending tasks and material profiles. Whether working with structural components or custom designs, the HSR-3 machines deliver consistent and reliable results, meeting the demands of industries such as construction, manufacturing, and metal fabrication.

Advanced Roll Design for Superior Performance

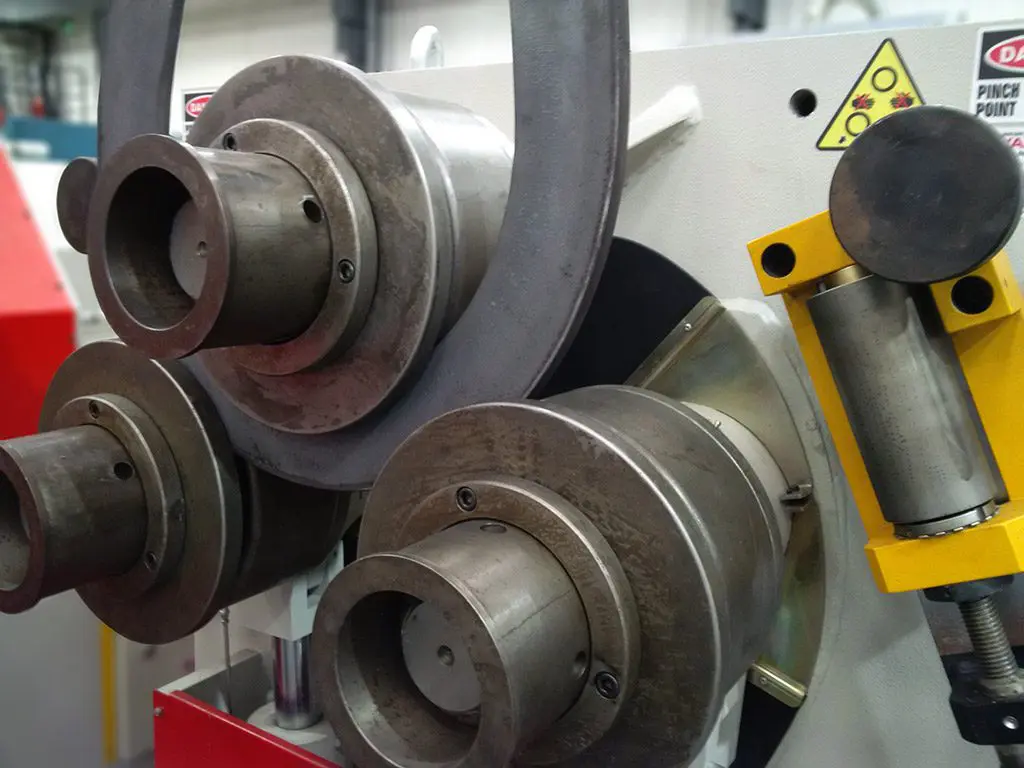

The Morgan Rushworth HSR-3 machines are equipped with hardened standard rolls, specifically designed to handle most section types with precision and durability. These rolls ensure smooth and accurate bending across a variety of profiles, including flat bars, angles, and box sections. For round tubes, optional tools are available to provide the same level of precision and performance, catering to applications that require specialised bending capabilities.

The inclusion of lateral guide rolls adds another layer of precision to the HSR-3 range. These guide rolls ensure straight and true bending, eliminating distortions and maintaining the integrity of the material. Additionally, the guide rolls can be adjusted to allow for controlled spiraling of the material, offering more creative and functional bending options. This level of control makes the HSR-3 series an ideal choice for workshops looking to expand their bending capabilities while maintaining consistent quality.

Pre-Bending Capabilities for Cleaner Results

One of the standout features of the HSR-3 range is its twin hydraulic rams, which provide pre-bending capabilities to reduce flat sections at the ends of the profile. Pre-bending ensures that the material achieves a uniform curve throughout, eliminating the need for additional finishing processes. This not only enhances the quality of the final product but also improves overall efficiency, saving time and resources during production.

The ability to perform pre-bending in the horizontal position further streamlines the bending process. Operators can position and handle materials more easily, particularly when working with larger or heavier profiles. This ergonomic design improves workflow and reduces operator fatigue, contributing to a more productive and efficient workshop environment.

Dual-Plane Operation for Enhanced Versatility

The flexibility to operate in both vertical and horizontal planes is a defining characteristic of the HSR-3 series. Vertical operation is ideal for certain tasks that require gravity-assisted bending, while horizontal operation is better suited for handling larger or more awkwardly shaped materials. This dual-plane functionality allows operators to adapt the machine to different projects and workshop layouts, ensuring optimal performance in every scenario.

By combining vertical and horizontal operation with advanced roll and guide designs, the HSR-3 machines deliver unparalleled versatility. This makes them suitable for a wide range of industries and applications, from creating architectural components and structural supports to manufacturing custom parts for specialised projects.

Built for Durability and Long-Term Reliability

As with all Morgan Rushworth machines, the HSR-3 range is built to last. The robust construction of these machines ensures reliable performance even under heavy use, making them a dependable choice for demanding industrial environments. The hardened rolls and high-quality components minimise wear and tear, ensuring consistent results over time.

Maintenance is simplified by the machine’s thoughtful design, with easy access to key components for servicing and adjustments. This reduces downtime and ensures that the machines remain operational, even during intensive production cycles. For businesses prioritising durability and efficiency, the HSR-3 series represents a cost-effective investment in long-term productivity.

Applications Across Industries

The Morgan Rushworth HSR-3 machines are designed to meet the needs of a wide range of industries. In construction, they provide the precision required to bend structural components with tight tolerances. For architectural projects, the machines enable the creation of curved designs that add aesthetic appeal to buildings and structures. In manufacturing, their ability to handle various profiles and materials ensures they can adapt to diverse production requirements.

The versatility of the HSR-3 range is further enhanced by its optional tooling and adjustable guide rolls, making it suitable for both standard applications and more complex, custom projects. This adaptability ensures that the machines remain a valuable asset for workshops looking to expand their capabilities and take on new challenges.

Why Choose Morgan Rushworth HSR-3 Machines?

The Morgan Rushworth HSR-3 hydraulic section bending machines offer a unique combination of precision, versatility, and reliability. With features like pre-bending capabilities, dual-plane operation, and hardened rolls, these machines deliver exceptional performance across a variety of applications. Optional tools and adjustable lateral guides further enhance their functionality, allowing businesses to customise the machines to meet their specific needs.

Built for durability and long-term reliability, the HSR-3 series ensures consistent results and reduced maintenance requirements, making it a cost-effective solution for workshops of all sizes. Whether you’re working on structural components, architectural designs, or custom projects, the HSR-3 machines provide the tools and technology needed to achieve outstanding results.

Conclusion

The Morgan Rushworth HSR-3 Hydraulic Section Bending Machines are a versatile and high-performance solution for modern workshops and industries. With advanced features like pre-bending capabilities, dual-plane operation, and precision-engineered rolls, these machines deliver reliable, high-quality results for a wide range of applications.

Designed for durability and efficiency, the HSR-3 range is a smart investment for businesses seeking to enhance their bending capabilities and take on more complex projects. With the ability to handle diverse materials and profiles, these machines set a new standard in section bending, offering unmatched versatility and performance.

Product Specific Case Studies

Mogul Mechanical Engineering – One-Stop Shop

11th June 2025 by Dave Hargest

Mogul Mechanical Engineering Ltd is a fabrication business, based in Cwmbran. They prove a variety of steel erection services, fabricating.. More

MMK Engineering – Bringing Profiling In-House

13th October 2023 by Dave Hargest

MMK Engineering Ltd, based in Devon, work across the full spectrum of engineering, from designing small components to assembling entire.. More