Morgan Rushworth HFPV Hydraulic H Frame Press 415V

The HFPV H-Frame presses are designed for a variety of bending, forming, pressing, and straightening operations. These models include all the features of the popular HFP series, with the added functionality of side-to-side ram movement across the width of the machine. This feature provides greater versatility for handling more complex tasks with precision and ease.

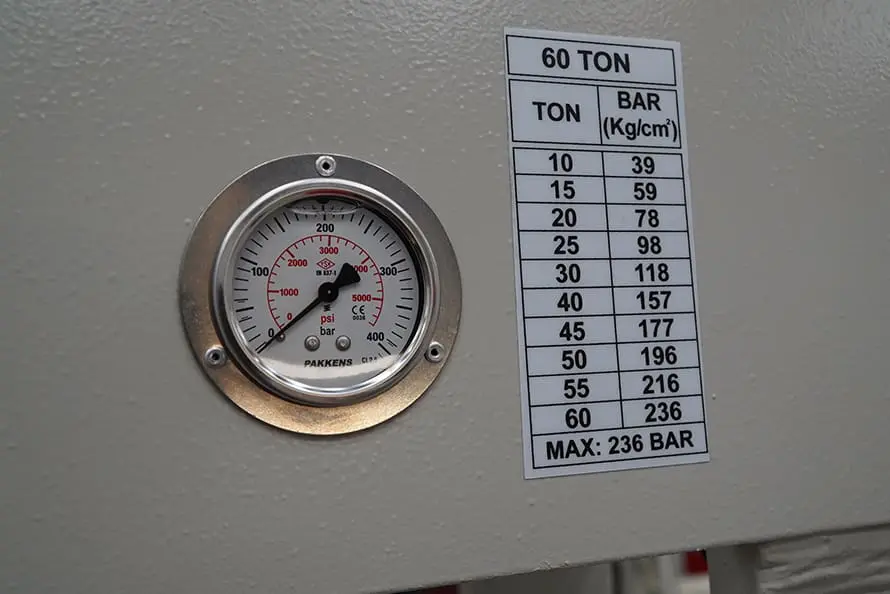

Equipped with a hydraulic system that includes a manometer for pressure monitoring and a joystick lever for intuitive control, the HFPV ensures accurate and reliable operation. Supplied with a pair of V blocks as standard, these presses are ready for immediate use, making them a practical and efficient choice for industrial applications.

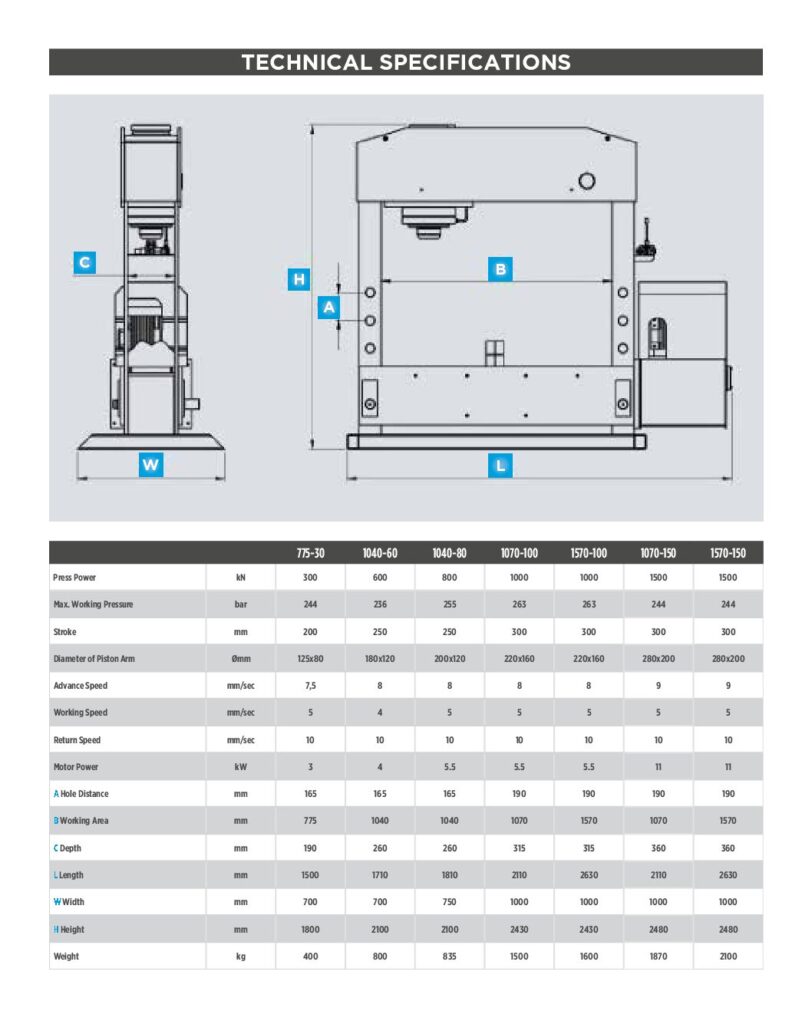

| MODEL | Power | Distance between Frames | Stroke | Advance speed | Working speed | Return speed | Motor power | Length | Width | Height | Weight | Ram Movement |

| Tonnes | mm | mm | mm/sec | mm/sec | mm/sec | kW | mm | mm | mm | Kg | Geared / Bearings | |

| HFPV-G 1570/100 | 100 | 1570 | 300 | 8 | 5 | 10 | 5.5 | 2560 | 1000 | 2480 | 1755 | Geared Handwheel |

| HFPV-G 1570/150 | 150 | 1570 | 300 | 9 | 5 | 10 | 11 | 2560 | 1000 | 2480 | 2350 | Geared Handwheel |

| HFPV-G 1900/200 | 200 | 1900 | 300 | 10 | 6.5 | 20 | 15 | 2650 | 1600 | 2700 | 4800 | Geared Handwheel |

| HFPV-B 775/30 | 30 | 775 | 200 | 7.5 | 5 | 10 | 3 | 1500 | 700 | 1800 | 400 | Bearings with Handle |

| HFPV-B 1040/60 | 60 | 1040 | 250 | 8 | 4 | 10 | 4 | 1710 | 700 | 2100 | 800 | Bearings with Handle |

| HFPV-B 1040/80 | 80 | 1040 | 250 | 8 | 5 | 10 | 5.5 | 1810 | 750 | 2100 | 835 | Bearings with Handle |

| HFPV-B 1070/100 | 100 | 1070 | 300 | 8 | 5 | 10 | 5.5 | 2110 | 1000 | 2430 | 1500 | Bearings with Handle |

| HFPV-B 1570/100 | 100 | 1570 | 300 | 8 | 5 | 10 | 5.5 | 2630 | 1000 | 2430 | 1600 | Bearings with Handle |

| HFPV-B 1070/150 | 150 | 1070 | 300 | 9 | 5 | 10 | 11 | 2110 | 1000 | 2480 | 1870 | Bearings with Handle |

| HFPV-B 1570/150 | 150 | 1570 | 300 | 9 | 5 | 10 | 11 | 2630 | 1000 | 2480 | 2100 | Bearings with Handle |

Features

- Geared Handwheel Piston Adjustment / Ball Bearing with Handle Adjustment

- Easily adjusted bed height with two hardened pins

- Bed designed to accept a variety of supports and jigs according to customer requirements

- Quiet hydraulic system

- Hydraulic cylinder mounted above providing vertical pressure

- Side to side ram movement across the width of the machine

- Ideal for low or high volume operation.

Options

- Adjustable Pressure Valve

- Digital Read Out

- Hand Pump

- Foot Pedal Control (instead of joystick)

- Foot Pedal Control with Limit Switch (instead of joystick)

Morgan Rushworth HFPV H-Frame Presses: Versatility and Innovation

Morgan Rushworth has long been synonymous with quality and innovation in industrial machinery, and the HFPV H-Frame presses continue this tradition. Designed to meet the diverse needs of modern workshops, these presses are ideal for bending, forming, pressing, and straightening operations. Building on the proven features of the popular HFP series, the HFPV models introduce side-to-side ram movement across the machine’s width, offering enhanced versatility and precision for more complex applications.

The HFPV series combines robust construction, advanced hydraulic systems, and practical design to provide a reliable and flexible solution for a variety of industries, including metal fabrication, automotive manufacturing, and general engineering. Whether for standard tasks or bespoke projects, Morgan Rushworth HFPV H-Frame presses deliver the performance, precision, and durability that workshops depend on.

Key Benefits of the Morgan Rushworth HFPV H-Frame Presses

1. Enhanced Flexibility with Side-to-Side Ram Movement

One of the standout features of the HFPV series is its side-to-side ram movement, which allows operators to position the ram precisely where needed across the machine’s width. This feature is invaluable for handling larger or irregularly shaped components, eliminating the need to reposition materials manually. It enhances workflow efficiency and provides greater flexibility for tackling complex and customised operations.

2. Advanced Hydraulic System for Precise Control

Morgan Rushworth has equipped the HFPV presses with a high-quality hydraulic system that combines power with precision. Featuring a manometer for monitoring pressure levels and a joystick lever for intuitive control, the hydraulic system ensures accurate and smooth operation. This advanced system allows operators to fine-tune the machine’s performance for specific tasks, enhancing accuracy and reducing the risk of errors.

3. Durability and Stability for Heavy-Duty Applications

Built with a robust H-frame construction, the HFPV presses are designed to withstand the rigours of daily industrial use. The heavy-duty frame minimises vibrations during operation, ensuring stability and consistent results. This durability makes the HFPV series ideal for high-pressure tasks, delivering reliable performance even in demanding environments.

4. Ready-to-Use with Standard Accessories

Morgan Rushworth includes a pair of V blocks as standard equipment with the HFPV presses, ensuring they are ready for immediate use. These accessories provide a stable and secure surface for bending and forming tasks, enhancing the machine’s versatility. The inclusion of practical tools reflects Morgan Rushworth’s commitment to providing complete solutions that meet the needs of industrial users.

5. Customisation with Tee-Slotted Ram Plates

The tee-slotted ram plates featured in the HFPV presses allow for easy fixture of customised tools, further expanding the machine’s capabilities. This feature is especially valuable for workshops that frequently work on specialised or bespoke projects. The ability to adapt the press to different applications ensures that it remains a versatile and cost-effective asset for any business.

Practical Design for Modern Workshops

Morgan Rushworth has designed the HFPV H-Frame presses with practicality in mind, ensuring that they are both easy to use and highly adaptable. The intuitive controls and clear layout make the presses accessible to operators of varying skill levels, reducing training time and enhancing productivity. The addition of side-to-side ram movement adds a new dimension of flexibility, making the HFPV series an excellent choice for workshops that handle a variety of tasks.

The compact design of the HFPV presses allows them to be integrated into a wide range of workspaces without occupying excessive floor space. This makes them suitable for businesses of all sizes, from smaller workshops to large industrial facilities. By combining compactness with functionality, Morgan Rushworth has created a machine that meets the demands of modern manufacturing.

Long-Term Reliability and Efficiency

Durability and efficiency are hallmarks of the Morgan Rushworth brand, and the HFPV H-Frame presses are no exception. The robust construction and high-quality hydraulic components ensure that the presses perform consistently over time, reducing the need for maintenance and minimising downtime. This long-term reliability makes the HFPV series a smart investment for businesses looking to enhance their capabilities while maintaining operational efficiency.

Additionally, the advanced hydraulic system and precise controls enable operators to complete tasks quickly and accurately, improving workflow efficiency. By reducing material handling time and ensuring consistent results, the HFPV presses help businesses achieve higher productivity and better outcomes for their projects.

Conclusion

The Morgan Rushworth HFPV H-Frame presses are a testament to the company’s commitment to quality, innovation, and practicality. Designed to handle a wide range of industrial applications with precision and reliability, these presses offer a versatile and efficient solution for bending, forming, pressing, and straightening operations. The introduction of side-to-side ram movement sets the HFPV series apart, providing enhanced flexibility for more complex tasks.

With features such as an advanced hydraulic system, robust construction, tee-slotted ram plates, and practical accessories like V blocks, the HFPV presses combine strength, precision, and ease of use. Their durable design ensures long-lasting performance, while their adaptability makes them suitable for various industries. For workshops seeking a dependable and versatile press that can meet the challenges of modern manufacturing, the Morgan Rushworth HFPV H-Frame presses represent an excellent investment. By delivering consistent results and exceptional reliability, these presses uphold the high standards associated with the Morgan Rushworth name.

Related Case Studies

Mogul Mechanical Engineering – One-Stop Shop

11th June 2025 by Dave Hargest

Mogul Mechanical Engineering Ltd is a fabrication business, based in Cwmbran. They prove a variety of steel erection services, fabricating guarding, platforms, ladders etc, as well as more complicated fabrications... More

MMK Engineering – Bringing Profiling In-House

13th October 2023 by Dave Hargest

MMK Engineering Ltd, based in Devon, work across the full spectrum of engineering, from designing small components to assembling entire end-use products and machinery. We spoke to Rob Jeffrey, Design.. More