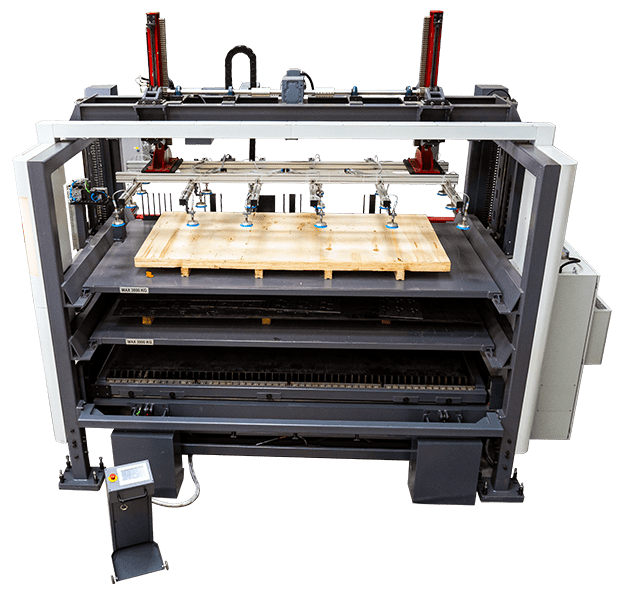

Morgan Rushworth Fibre Laser Compact Tower System

The Morgan Rushworth Compact Tower System allows you to get the maximum throughput from your Fibre Laser cutting machine. This tower stacker enables you to run machines at faster speeds, with continual loading and unloading of sheet material and cut parts, reducing the amount of time between cuts, and maximising the use of the operator’s time.

The Morgan Rushworth Compact Tower System is easily integrated into your production. Handle mirror-finish sheets with ease, as the efficient compact tower system can load and unload sheets with minimal tooling marks, grease or scratches.

Compatible with the Morgan Rushworth XR and Morgan Rushworth XS Fibre Laser Machines.

| Compact Automated Loading and Unloading Tower System | ||

| Max. Sheet Size | mm | 1,500 x 3,000 |

| Min. Sheet Size | mm | 1,000 x 1,000 |

| Max. Sheet Weight (Handling) | kg | 600 |

| Max. Material Stacking Weight (On Pallet) | kg | 3,000 |

| Max. Sheet Thickness | mm | 16 |

| Number of compartments | 2 Units (New Stock and Scrap) | |

| Max. Loading and Unloading Course | mm | 220 (Including Pallet) |

| Loading & Unloading Cycle Time* | seconds | 135 |

| Cycle Time: Starts with taking scrap sheet from transfer table to pull over on a pallet and then take a new sheet from the pallet to the transfer table | ||

Features

- Compatible with the XR & XS Fibre Laser Cutting Machines

- Automatic loading and storage of raw material

- Automatic unloading of parts and scraps

- Allows fully automatic running

- Sits in place of the standard pallet exchange, so no additional footprint taken up for the machine

- Pallet rack for raw material

Options

Morgan Rushworth Fibre Laser Compact Tower System

The Morgan Rushworth Compact Tower System is designed to revolutionise the efficiency and productivity of your fibre laser cutting operations. By enabling seamless loading and unloading of sheet material and cut parts, this innovative system ensures maximum throughput, reduced downtime, and optimised use of operator time. Compatible with the Morgan Rushworth XR and XS Fibre Laser Machines, the Compact Tower System is an essential addition for businesses aiming to enhance their production capabilities.

Maximise Throughput and Efficiency

At the heart of the Compact Tower System is its ability to significantly increase the productivity of your fibre laser cutting machine. Key benefits include:

- Continuous operation: The system allows for uninterrupted loading and unloading, reducing the time between cuts and keeping the machine running at peak efficiency.

- Optimised workflow: By automating material handling, operators can focus on other tasks, maximising their efficiency.

- High-speed processing: Paired with the rapid cutting speeds of Morgan Rushworth Fibre Laser Machines, the Compact Tower System ensures swift and seamless production.

This combination of efficiency and automation helps businesses achieve faster turnaround times and higher output, giving them a competitive edge.

Easy Integration into Existing Production Lines

The Morgan Rushworth Compact Tower System is designed for seamless integration into your existing production environment. Key features include:

- Simple setup: The system can be easily incorporated with Morgan Rushworth XR and XS Fibre Laser Machines, minimising installation time and disruption.

- Compact design: Despite its high capacity, the tower system has a space-saving design that makes it suitable for workshops of all sizes.

- Versatile compatibility: The system can handle a wide range of materials, ensuring it meets the diverse needs of modern manufacturing.

By integrating the Compact Tower System into your production line, you can streamline operations and achieve a more organised and efficient workflow.

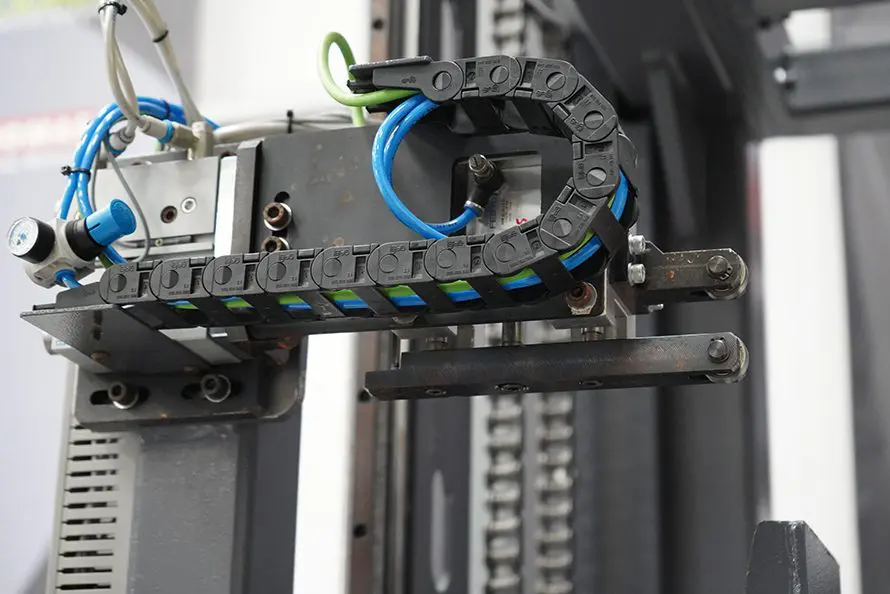

Gentle Material Handling

The Compact Tower System is equipped with advanced material handling capabilities to ensure the integrity of your materials. Key highlights include:

- Scratch-free operation: Specialised handling mechanisms minimise tooling marks, grease, and scratches, making it ideal for mirror-finish sheets and delicate materials.

- Precision alignment: Materials are loaded and unloaded with exceptional accuracy, ensuring consistent performance and quality.

- Reduced manual intervention: By automating the handling process, the system reduces the risk of human error, improving overall reliability.

These features ensure that your materials maintain their quality throughout the production process, reducing waste and enhancing customer satisfaction.

Enhanced Productivity with Automation

Automation is at the core of the Morgan Rushworth Compact Tower System. By automating repetitive tasks, the system offers significant productivity benefits:

- Labour savings: Automation reduces the reliance on manual labour, allowing operators to focus on higher-value tasks.

- Increased machine utilisation: Continuous loading and unloading ensure that the fibre laser machine operates at maximum capacity.

- Efficient batch processing: The system supports large-scale production runs, making it ideal for high-volume manufacturing environments.

These automation features not only boost productivity but also contribute to a safer and more ergonomic workplace.

Applications Across Industries

The Morgan Rushworth Compact Tower System is versatile and adaptable, making it suitable for a wide range of industries, including:

- Automotive: Processing components for vehicles and prototypes.

- Fabrication: Producing custom parts for construction and manufacturing.

- Signage and graphics: Cutting intricate designs and lettering.

- Aerospace: Creating high-precision parts for critical applications.

- Energy sector: Manufacturing components for renewable energy systems and industrial equipment.

Its adaptability ensures that businesses in diverse sectors can benefit from its advanced capabilities.

Cost Efficiency and Long-Term Value

Investing in the Morgan Rushworth Compact Tower System delivers long-term cost-saving benefits, including:

- Reduced material waste: Precision handling minimises material damage, saving costs on replacements.

- Lower labour costs: Automation reduces the need for manual material handling.

- Improved energy efficiency: The system’s streamlined operations contribute to overall energy savings.

These cost efficiencies make the Compact Tower System a smart investment for businesses looking to improve their bottom line.

Seamless Compatibility with XR and XS Fibre Laser Machines

The Compact Tower System is fully compatible with the Morgan Rushworth XR and XS Fibre Laser Machines, enhancing their already impressive capabilities. When combined with the high-speed, high-precision cutting of these machines, the tower system creates a production powerhouse that meets the demands of modern manufacturing.

Conclusion

The Morgan Rushworth Compact Tower System is a game-changer for businesses seeking to optimise their fibre laser cutting operations. With its ability to automate material handling, maximise throughput, and protect material quality, this system delivers unparalleled efficiency and reliability. Its compatibility with Morgan Rushworth XR and XS Fibre Laser Machines makes it a perfect addition to any production line, ensuring seamless integration and enhanced productivity.

Invest in the Morgan Rushworth Compact Tower System today and experience the next level of automation and efficiency. From reducing downtime to improving material handling, this system is the ultimate solution for businesses aiming to stay competitive in the ever-evolving world of manufacturing.