Morgan Rushworth XTR Tube Fibre Laser

The Morgan Rushworth XTR Tube Fibre lasers are capable of processing up to 8,000mm tubes. With a maximum part length of 4,000mm, this machine can handle large and small parts with ease.

Featuring the Precitec Light Cutter 3D, the system can handle a multitude of profiles, including Round, Rectangular, Triangular, C, U, L, Elliptical, Obround and Custom Shapes, with diameters minimum of Ø12 up to a maximum of Ø220 mm with wall thicknesses from 0.8 – 12mm.

Optional additions includes bevel cutting and automated loading and unloading systems.

| Stock Code | XTR 6160 | XTR 6220 | XTR 8220 | |

| CNC Control Unit | Beckhoff CNC (18.5″ TFT – Windows 10) | |||

| Cutting Head | Precitec LightCutter 2.0 3D | |||

| Max. Tube Length | mm | 6,100 | 8,100 | |

| Max. Part Length | mm | 2,000 – 6,000 | 4,000 – 8,000 | |

| Min. Auto Loading Length | mm | 2,000 | ||

| Acceleration of Drive Chuck | °/s2 | 7,000 | ||

| Speed of Driver Chuck | °/s | 560 | ||

| Types of Profile | Round, Rectangular, Triangular, H, C, U, L, Elliptical, Obround and Custom Shapes | |||

| Min. / Max. Round Diameter | mm | Min Ø12 / Max Ø160 | Min Ø16 / Max Ø220 | |

| Min. / Max. Square Diameter | mm | Min 12 x 12 / Max 160 x 160 | Min 16 x 16 / Max 220 x 220 | |

| Length of Last Part | mm | 60 | ||

| Max. Tube Weight | kg/m | 240 | ||

| Min. Material Thickness | mm | 0.8 | ||

| Rapid Travese | m/min | 90 | ||

| Vector Speed | m/min | 50 | ||

| Acceleration | m/s2 | 1.0G | ||

| Absolute Positioning Accuracy | mm | ± 0.01 | ||

| Repeatability (X & Y Axis) | mm/mt | ± 0.02 | ||

| Bevel Cutting (± 45º) | Optional | |||

| Automatic Loading / Unloading | Optional | |||

| Feed Rate | m/min | Programmable up to 45 m/min. Actual feed rate depends on material and thickness. | ||

Features

- High performance IPG / Max Photonics Fibre Laser Source

- Lantek Flex3d Software

- Fibre optic beam delivery system

- Ease of processing for Large and Small size tube and profiles

- Rapid processing, programmable up to 45m/min

- Precitec Lightcutter 2.0 3D Laser Cutting Head

- High strength, rigid gantry design to ensure high accuracy and allow high acceleration

- Applicable tube types : Round, Rectangular, Triangular, H, C, U, L, Elliptical, Obround and Custom Shapes

- CE compliant complete machine enclosure and light barrier system

- High automation level and shorter configuration times

- More parts produced per day

- Profile Length measuring

- Tube centring (Laser Sensors)

- Tube Transfer System

- Automatic Weld Recognition

- Simple and User-Friendly operator interface and cutting database

Options

- Bevel Cutting

- Fume extractor with filters

- Air compressor and dryer

- Automated Loading and unloading systems

The Morgan Rushworth XTR Tube Fibre lasers are capable of processing up to 8,000mm tubes. With a maximum part length of 4,000mm, this machine can handle large and small parts with ease.

Featuring the Precitec Light Cutter 3D, the system can handle a multitude of profiles, including Round, Rectangular, Triangular, C, U, L, Elliptical, Obround and Custom Shapes, with diameters minimum of Ø12 up to a maximum of Ø220 mm with wall thicknesses from 0.8 – 12mm.

Optional additions includes bevel cutting and automated loading and unloading systems.

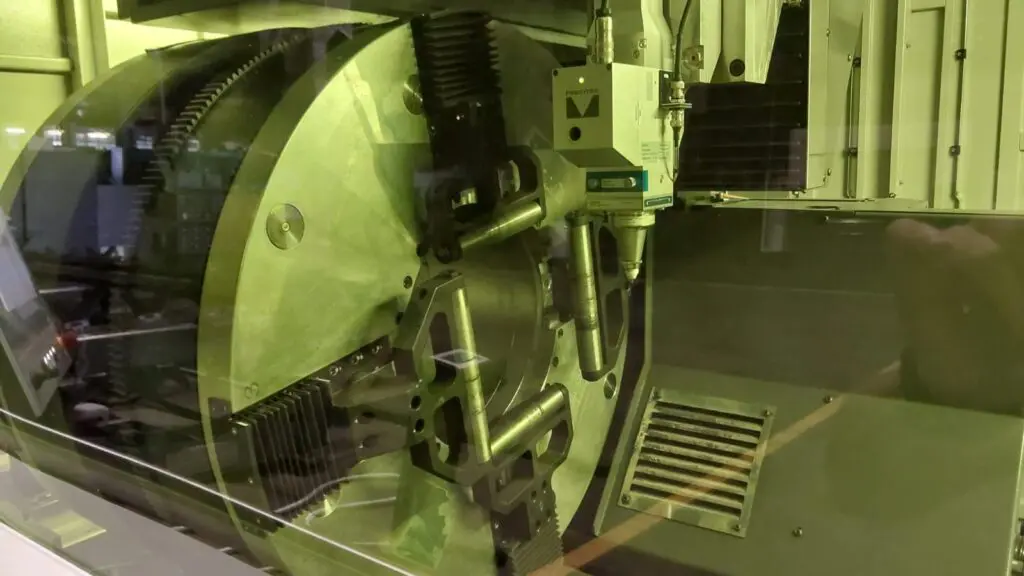

Precitec LightCutter 2.0 3D Cutting Head

The LightCutter 2.0 is designed for high laser power. It is completely dust-tight, which guarantees a continuous, clean operation. The basis for clean cut edges is provided by the ultra-stable and drift-free sensor technology for a constant distance between component and optics.

Complex cutting contours are approached quickly and precisely with the LightCutter 2.0 3D. The slim design in the front area allows contact-free immersion in areas that are very difficult to access. The narrow contour of the 3D cutting head’s lower section enables even complex cuts on tubes, profiles and free-form parts with an inclination angle of up to 45 degrees.

- Distance to the work piece remains always the same via capacitive sensor.

- The laser head is equipped with a cassette system for quick lens replacement.

- Cutting head includes lens protective mirror. This feature saves cutting lens and ensure long life usage. Easy interchangeable and low-cost protective mirror allows you to work freely without worrying about the Lens.

- The cutting head is equipped with a crash protection system – In case of collision with the work piece the head easily separates to avoid any damage.

Simple to use, advanced HMI

One of the biggest advantages of Morgan Rushworth Laser Machines is our advanced HMI; it comes as standard on all Morgan Rushworth Fibre Laser models.

Morgan Rushworth R&D engineers have been created Morgan Rushworth HMI from years of high experience on cutting machines. Morgan Rushworth HMI offers plenty of features to make machines easier to use for the operators, it’s been improved with feedbacks from customers during previous years.

Morgan Rushworth HMI is fully integrated with Industry 4.0. All cutting parameters can be monitored and intervened by operators during cutting process. Integrated with IPG-nLIGHT Monitoring software; this allows users to check the online status of resonators.

Morgan Rushworth HMI has English, German, Spanish and Polish language options are available.

- One touch menu to reach all machine HMI pages

- Graphically real-time cutting monitoring

- Multi-touch (on) part program graphic view

- Safety warnings and graphical diagnostic

- Graphical zooming on parts program

- Easy to find every counter with “Block Search”

- Extensive cutting parameters database

- Detects errors during cutting process

- Control of laser power on different materials

- Automatic profile detection

- Allows to change parameters during cutting process

- Automatic multiple parts cutting process

- Fully integrated with Industry 4.0

- Power and frequency ramping on piercing

- Power ramping depending on cutting speed.

- Burr Cleaning with cutting gas

- Lead-in start hole

3D Bevel Head (Optional)

The Optional 3D Bevel Head is is suitable for vertical and bevel cuts between 0 ° to 45 °. The 3D Bevel head is equipped with Backlash free “Harmonic Drive” motor.

| Positioning Speed in Y Axis | m/min | 100 |

| Positioning Speed in Z Axis | m/min | 30 |

| Cutting Speed | m/min | Up to 10 |

| Angled Cutting Precision | degree | +/- 3 |

| Minimum angled cutting thickness | mm | 3 |

Beckhoff Industrial PC

It’s a very important and critical part of the machine, the laser safe cabin and enclosure ensures that operators are protected from the potential dangers of a Class 4 Laser, as per CE Regulations.

Beckhoff Industrial PC

The multi-touch panel series from Beckhoff offers the greatest possible flexibility. The Beckhoff multi-touch panels with projective capacitive touch screen (PCT) technology feature a high touch-point density, which enables accurate, safe and jerk-free operation even in minute steps.

Zooming, scrolling, object turning, flicks etc. are now also usable for industrial applications with the multi-touch devices.

Beckhoff servo motors and drivers

Morgan Rushworth Laser Systems are using advanced and latest Beckhoff high quality servo motors and drivers, which represents robust, durable and high-performance synchronous servomotors “Made in Germany”.

The servomotor range AM8000 stands for durable and powerful synchronous servomotors. High-performance AM8000 Synchronous Servomotors are characterised by high dynamics, energy efficiency and reduced lifecycle costs.

Beckhoff Servo Drive product line sets new standards in drive performance, AX5000 drives support fast and highly dynamic positioning tasks. The drives utilize EtherCAT as a high-performance communication system, providing an ideal interface with PC-based control technology while supporting coupling with other fieldbus systems.

Twincat CNC by Beckhoff

TwinCAT CNC offers complete CNC functionality as a pure PC-based software solution. TwinCAT CNC covers the complete range of classic CNC path control, including high-end systems for complex motion and kinematics requirements.

Lantek Flex3D Tubes

Lantek Flex3d Tubes integrates with various kinds of tubular geometry importers such as SAT and IGES. This software allows 3D design to be simple and intuitive. It gives a true vision of the resulting design profile that will eventually be cut on a machine.

This system is a parametric system which allows the user to change the values of any operations previously made, including changes to the initial parameters of each tube (lengthening, shortening, change of diameter).

Once the design stage is complete, the user can simulate optimisation of the tube (nesting) and the path followed by the cutting head. The software will directly generate the NC program in order to send this optimisation to the machine.

- Provides a real vision of the expected result on the screen.

- Displays the exact tube and simulates 3D and each process, thus reducing errors.

- Allows for easy manipulation and editing of the design with zoom, view, and rotation controls.

- Offers the user the ability to create standard tubes based on requirements.

- Allows the user to design tube types adapted to their needs from 2D outlines, in addition to cylindrical, rectangular, and triangular tubes.

- Allows for the design or import of desired geometry to create any type of cut-out or trim with 2D design options.

- Lantek Flex3d Tubes is totally integrated with Lantek’s management systems.

nLight Alta™ Compact Fibre Laser

nLIGHT alta™ compact fibre lasers are the next generation of high power fibre lasers. Designed to meet the performance and reliability requirements for industrial applications, nLIGHT alta™ compact is the highest power, smallest footprint fibre laser.

Improved Cutting and Welding Performance: nLIGHT alta™ is capable of delivering a modulation rate up to 100 kHz and rise and fall time of less than 5 µs. Enabled by next generation electronics, these capabilities

allow faster piercing, faster processing of fine features, and smaller heat affected zones.

Back Reflection Isolation: nLIGHT’s novel back reflection isolation technology allows uninterrupted full power processing of highly

reflective materials.

The nLIGHT alta™ fibre laser platform is designed and manufactured in the U.S., leveraging nLIGHT’s vertically integrated high brightness laser diode and fiber technology, and is supported through a global network of sales and service staff.

Fume Filtration System (Optional)

Filter Type: Panel Pleated Surface Filtration Dust Class M and H14 ePTFE membrane Polyester Non-woven, HEPA14 filtration quality.

- Average life – time of panel filters is apprx. 20.000 hours.

- Filter Efficiency Over 99,997% of 0,12 micron particles.

- W3/IFA certified according to EN ISO 15012 standard.

- Low operating cost thanks to superior long filter life time.

- Integrated pre-separator minimize the fire risks.

- Operator-friendly dust bin design: No contact with contamination during handling.

3D Bevel Head (Optional)

The Optional 3D Bevel Head is is suitable for vertical and bevel cuts between 0 ° to 45 °. The 3D Bevel head is equipped with Backlash free “Harmonic Drive” motor.

| Positioning Speed in Y Axis | m/min | 100 |

| Positioning Speed in Z Axis | m/min | 30 |

| Cutting Speed | m/min | Up to 10 |

| Angled Cutting Precision | degree | +/- 3 |

| Minimum angled cutting thickness | mm | 3 |