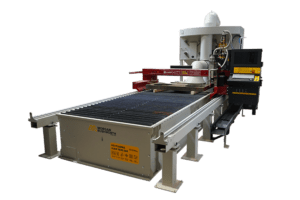

Morgan Rushworth ACP CNC HPR High Definition Plasma Cutting Machine

The Morgan Rushworth ACP CNC Compact Plasma Cutting Machines are designed for precise, efficient cutting of sheet and plate materials. With an intuitive Windows-based CNC controller, they offer exceptional accuracy and ease of use.

Powered by the Hypertherm Powermax 105 with single-gas plasma technology, they can be upgraded to the MAXPRO200 or HPR130XD with XD Truehole technology for enhanced performance. These machines maximise productivity, minimise costs, and deliver superior cut quality and reliability, making them a cost-effective solution for metal fabrication.

| MODEL | ACP 1530/105 | ACP 15 60/105 | ACP 2040/105 | ACP 2060/105 | ||

| Plasma Output | Amps | 105 | 105 | 105 | 105 | |

| Capacity from Pierce | Mild Steel | mm | 20 | 20 | 20 | 20 |

| Stainless Steel | mm | 20 | 20 | 20 | 20 | |

| Aluminium | mm | 20 | 20 | 20 | 20 | |

| Capacity from Edge Start | Mild Steel | mm | 40 | 40 | 40 | 40 |

| Stainless Steel | mm | 32 | 32 | 32 | 32 | |

| Aluminium | mm | 32 | 32 | 32 | 32 | |

| Table Width | mm | 1600 | 1600 | 2075 | 2075 | |

| Table Length | mm | 3100 | 6100 | 4285 | 6285 | |

| X Axis Stroke | mm | 1550 | 1550 | 2050 | 2050 | |

| Y Axis Stroke | mm | 3050 | 6050 | 4050 | 6050 | |

| Z Axis Stroke | mm | 150 | 150 | 150 | 150 | |

| Table Height | mm | 800 | 800 | 925 | 925 | |

| Length | mm | 4420 | 7420 | 6084 | 8084 | |

| Width | mm | 2350 | 2350 | 2720 | 2720 | |

| Height | mm | 1710 | 1710 | 1723 | 1723 | |

| Weight | kg | 2550 | 4950 | 3950 | 5600 | |

Features

- Hypertherm Powermax 105 high definition multi gas plasma source

- Windows based Hypertherm MicroEDGE Pro CNC controller

- Hypertherm Nesting Software options

- Automatic torch height control

- Torch collision protection system

- Automatic ventilation and smoke extraction system ready to be connected to a filtration system

- Positioning speed 30 m/min maximum

- Positioning accuracy +/- 0.02mm

- LMT 25 mm high accuracy linear rail

- High quality Eisele gearbox

- Mitsubishi servo motor

- Atlanta rack and pinion system

- Moveable Control Panel with gantry control joystick

Options

- NestMaster automatic nesting software

- TurboNest nesting software and additional productivity modules

- ProNest nesting software and additional productivity modules

- Extraction/filtration system

- Automatic gas console

Morgan Rushworth ACP CNC HPR High Definition Plasma Cutting Machine

The Morgan Rushworth ACP CNC Compact Plasma Cutting Machines are the epitome of precision and efficiency in metal fabrication. Engineered for the cutting of sheet and plate materials, these machines combine advanced technology with user-friendly features, ensuring exceptional performance and reliability. Their compact design makes them a versatile solution for workshops of all sizes, catering to a wide range of cutting applications.

Advanced CNC Controller for Precision Cutting

At the heart of the Morgan Rushworth ACP CNC Plasma Cutting Machine is an intuitive Windows-based CNC controller. This advanced system simplifies operation while maintaining high precision, making it accessible to both experienced operators and novices. The user-friendly interface allows for seamless programming and execution of cutting tasks, ensuring consistent and accurate results every time. This intuitive control system reduces the learning curve and maximises productivity, even in high-demand environments.

Power and Versatility with Hypertherm Technology

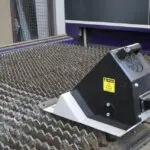

The ACP CNC Plasma Cutting Machines come equipped with the powerful Hypertherm Powermax 105, a single-gas plasma cutting system renowned for its performance and reliability. For those seeking enhanced capabilities, the machine can be upgraded to:

- MAXPRO200: A high-performance plasma system for demanding industrial applications.

- HPR130XD with XD Truehole Technology: Delivers superior hole quality, improved cut accuracy, and reduced edge taper, setting a new standard in plasma cutting precision.

These upgrade options ensure that the ACP series can be tailored to meet specific cutting requirements, from general fabrication to high-precision industrial tasks.

Cost-Effective Metal Fabrication Solution

The Morgan Rushworth ACP CNC Plasma Cutting Machines are designed to maximise productivity while minimising operational costs. Their efficient cutting technology reduces material waste and energy consumption, delivering significant cost savings over time. Additionally, the durability and reliability of the components ensure minimal maintenance requirements, further enhancing the machine’s cost-effectiveness.

Superior Cut Quality and Accuracy

The integration of advanced plasma technology allows the ACP series to deliver exceptional cut quality across a variety of materials. Whether cutting mild steel, stainless steel, or aluminium, these machines produce clean edges with minimal post-processing required. The inclusion of XD Truehole Technology on the HPR130XD upgrade ensures unmatched precision in hole cutting, making it ideal for applications requiring tight tolerances and high-quality finishes.

Key Features of the Morgan Rushworth ACP CNC Plasma Cutting Machines

- Windows-Based CNC Controller: Intuitive and user-friendly interface for seamless operation.

- Standard Hypertherm Powermax 105: Reliable and efficient plasma cutting system.

- Upgrade Options: MAXPRO200 and HPR130XD with XD Truehole Technology for enhanced performance.

- Compact Design: Space-saving footprint suitable for workshops of all sizes.

- Superior Cut Quality: Clean edges and accurate cuts across a variety of materials.

- Cost Efficiency: Reduced material waste, energy consumption, and maintenance costs.

- Durable Construction: Built to withstand demanding industrial environments.

Applications Across Industries

The Morgan Rushworth ACP CNC Plasma Cutting Machines are versatile enough to meet the demands of various industries, including:

- Metal Fabrication: Ideal for cutting structural steel, sheet metal, and plates for construction and manufacturing.

- Automotive: Precision cutting of components and parts for vehicles and machinery.

- Aerospace: High-quality cutting of aluminium and stainless steel for aircraft components.

- General Engineering: Versatile solution for creating bespoke parts and components.

This adaptability ensures that the ACP series is a valuable addition to any workshop, regardless of the industry or application.

Why Choose Morgan Rushworth ACP CNC Plasma Cutting Machines?

Investing in the Morgan Rushworth ACP series means choosing a machine that combines advanced technology with cost-effective operation. The flexibility of upgrade options allows businesses to tailor the machine to their specific needs, ensuring long-term value. Additionally, the intuitive CNC controller and exceptional cut quality make these machines a reliable choice for improving productivity and achieving consistent results.

Conclusion

The Morgan Rushworth ACP CNC HPR High Definition Plasma Cutting Machines deliver precision, efficiency, and reliability in metal fabrication. With their advanced CNC controller, powerful Hypertherm technology, and upgrade options, these machines are designed to meet the diverse needs of modern workshops. Whether you’re cutting mild steel, stainless steel, or aluminium, the ACP series offers unmatched performance and cost efficiency. Elevate your metal fabrication capabilities with the Morgan Rushworth ACP CNC Plasma Cutting Machines and experience the benefits of superior cut quality and reliability.