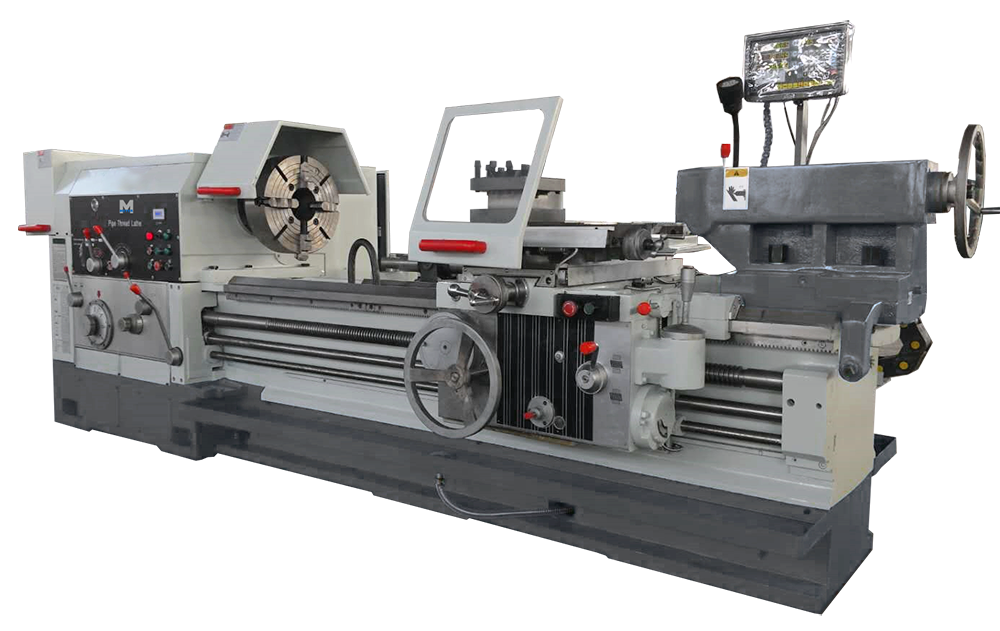

Meyer Pipe Threading Lathes

The Meyer Series Pipe Thread Lathe is specially developed for processing API Pipe Thread in the oil field industry. It features a large through hole on the main shaft and a front and rear double chuck tightening structure, making it suitable for turning various long pipe cylindrical threads, conical threads and special threads. It also performs all general lathe functions and can replace a standard lathe to process shafts, sleeves and disc parts, including turning inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooves, chamfers, and threads.

The machine is robust, with a simplified control panel, heavy-duty construction, and stable performance. It is widely used in oil, gas, chemical, hydropower and geological industries.

| Capacities | PT1080 | PT1580 | PT2080 | PT3080 | PT4080 | |

| Swing over Bed | mm | 800 | 800 | 800 | 800 | 800 |

| Tube Outside Diameter | mm | 20 – 198 | 20 – 198 | 20 – 198 | 20 – 198 | 20 – 198 |

| Swing over Gap | mm | 900 | 900 | 900 | 900 | 900 |

| Length of Gap | mm | 300 | 300 | 300 | 300 | 300 |

| Distance between Centres | mm | 1000 | 1500 | 2000 | 3000 | 4000 |

| Feed Rates | ||||||

| Longitudinal – no.of steps | – | 26 | 26 | 26 | 26 | 32 |

| Longitudinal – range | mm/rev | 0.07 – 1.33 | 0.07 – 1.33 | 0.07 – 1.33 | 0.07 – 1.33 | 0.1 – 1.5 |

| Thread Cutting | ||||||

| Metric – no. of steps | – | 23 | 23 | 23 | 23 | 23 |

| Metric – range | mm | 1 – 15 | 1 – 15 | 1 – 15 | 1 – 15 | 1 – 15 |

| Imperial – no. of steps | – | 26 | 26 | 26 | 26 | 22 |

| Imperial – range | TPI | 1 – 14 | 1 – 14 | 1 – 14 | 1 – 14 | 2 – 28 |

| Lead Screw Pitch | mm | 12 | 12 | 12 | 12 | 12 |

| Headstock | ||||||

| Spindle Bore | mm | 200 | 200 | 200 | 200 | 200 |

| Spindle Speeds – no. of steps | – | 2 | 2 | 2 | 2 | 2 |

| Spindle Speeds – range | rpm | 20 – 450 | 20 – 450 | 20 – 450 | 20 – 450 | 20 – 400 |

| Tailstock | ||||||

| Quill Diameter | mm | 100 | 100 | 100 | 100 | 100 |

| Quill Travel | mm | 250 | 250 | 250 | 250 | 230 |

| Quill Taper | MT | M5 | M5 | M5 | M5 | M5 |

| Power | ||||||

| Motor | kW | 11 | 11 | 11 | 11 | 11 |

| Dimensions | ||||||

| Length | mm | 3600 | 3900 | 4400 | 5400 | 6200 |

| Width | mm | 1620 | 1620 | 1620 | 1620 | 1550 |

| Height | mm | 1600 | 1600 | 1600 | 1600 | 1500 |

| Weight | kg | 4100 | 4850 | 5150 | 6600 | 8800 |

Features

- Heavy duty chuck guard

with interlock switch - Large Spindle Bore capacity

- Halogen lamp

- Steady rest

- Follow rest

- 4 jaw chuck

- Face plate

- Coolant system

- 2 axis DRO

Options

- Taper turning attachment

Meyer Series Pipe Thread Lathe

The Meyer Series Pipe Thread Lathe is a specialist machine, expertly engineered to meet the rigorous demands of the oil field and pipe processing industries. Designed for versatility, durability, and precision, this lathe excels in the machining of long pipes and a wide range of thread profiles, while also offering all the functions of a conventional lathe. Its heavy-duty construction and advanced features make it an invaluable addition to any workshop or industrial facility requiring high-performance pipe threading and general turning operations.

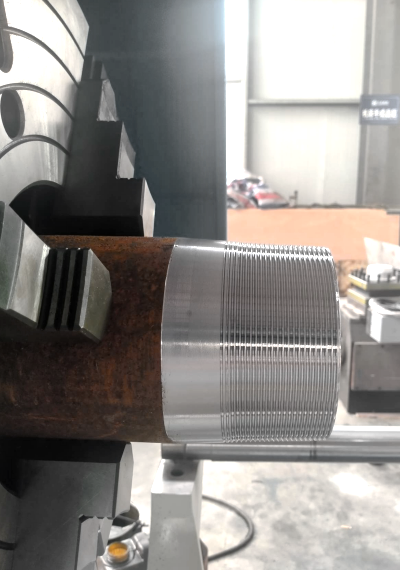

Purpose-Built for Pipe Threading

At the heart of the Meyer Series design is its ability to efficiently process API pipe threads, which are commonly used in the oil and gas sector. These threads require precise machining to ensure secure connections in pipelines, drilling equipment, and high-pressure systems. The lathe’s large through-hole spindle allows for the accommodation of long and wide pipes, eliminating many of the handling challenges found in smaller conventional lathes.

The Meyer Pipe Thread Lathe is equipped with a front and rear double chuck tightening structure. This system secures the workpiece firmly in place, significantly reducing vibration during cutting operations. The added stability allows for greater accuracy in thread cutting, whether producing cylindrical, conical or specialised thread forms. Operators can machine internal and external threads to exacting standards, ensuring each component meets industry specifications for fit, strength, and durability.

Full General Lathe Capabilities

In addition to its exceptional threading performance, the Meyer Pipe Thread Lathe offers full general-purpose turning functionality. This dual capability allows workshops to maximise productivity, using the same machine for both specialised pipe work and general component machining.

Operators can perform a wide range of machining tasks, including turning of inner and outer cylindrical surfaces, conical surfaces, arc surfaces, end faces, grooves, chamfers, and thread cutting. Whether producing shafts, sleeves, or disc parts, the Meyer Lathe maintains accuracy and surface finish across a variety of materials and component geometries.

Heavy-Duty Construction and Stability

One of the defining features of the Meyer Series Pipe Thread Lathe is its robust construction. Designed for heavy-duty industrial use, the lathe’s rigid frame and high-quality materials ensure long-term durability and consistent performance, even under continuous operation. The solid bed design reduces flexing and deformation during cutting, while the heavy base enhances stability, minimising any risk of workpiece deflection.

The use of precision-ground beds and carefully engineered saddle assemblies ensures smooth movement of the carriage, contributing to excellent machining accuracy. All components are designed to withstand the forces generated during high-torque threading and turning operations, extending the life of both the machine and cutting tools.

Simplified Control for Operator Efficiency

Despite its advanced capabilities, the Meyer Pipe Thread Lathe is designed with the operator in mind. The control panel is simple and intuitive, allowing even less-experienced machinists to operate the machine with confidence. Clear displays and logical control layouts reduce setup time, improve safety, and minimise the potential for operator error.

The ease of operation is further enhanced by the machine’s power-assisted functions, including rapid traverse for longitudinal and cross movements, automatic thread cutting cycles, and adjustable spindle speeds. These features combine to optimise productivity while maintaining high standards of precision.

Applications Across Multiple Industries

While originally developed for the oil field sector, the versatility of the Meyer Pipe Thread Lathe makes it suitable for a wide range of industries. It is commonly employed in:

-

Oil and Gas Industry: For producing casing, tubing, drill pipes, and threaded connectors.

-

Natural Gas Industry: For processing pipelines, compressors, and fitting assemblies.

-

Chemical Industry: For machining large pipework, pressure vessels, and specialised fittings.

-

Hydropower Sector: For manufacturing water pipelines, turbines, and associated fittings.

-

Geological Exploration: For creating drill rods, sample collection tubes, and drilling equipment components.

Its ability to handle large workpieces and cut various thread types makes it an excellent investment for companies involved in pipe production, repair, and custom machining.

Precision Engineering and Reliability

The Meyer Series Pipe Thread Lathe reflects a commitment to precision engineering and build quality. Every machine undergoes stringent quality control inspections to ensure reliability from the moment it enters service. Critical components are manufactured to tight tolerances, and the machine’s drive system is optimised for smooth, stable power delivery across its full speed range.

With routine maintenance, the Meyer Lathe provides years of dependable service, maintaining its precision and cutting performance even in demanding production environments. Its straightforward design also ensures that servicing and part replacement can be carried out quickly, minimising downtime and protecting productivity.

A Complete Pipe Threading Solution

In today’s demanding industrial landscape, the need for reliable, flexible and efficient machinery is greater than ever. The Meyer Series Pipe Thread Lathe offers an ideal solution for businesses involved in pipe manufacturing, maintenance, and custom thread cutting. Its combination of specialist threading capabilities with full general-purpose turning functions makes it a versatile workhorse for a wide range of machining tasks.

Whether deployed in a dedicated pipe processing facility or as part of a general machine shop, the Meyer Lathe delivers the accuracy, power and flexibility needed to meet the highest standards of modern engineering.