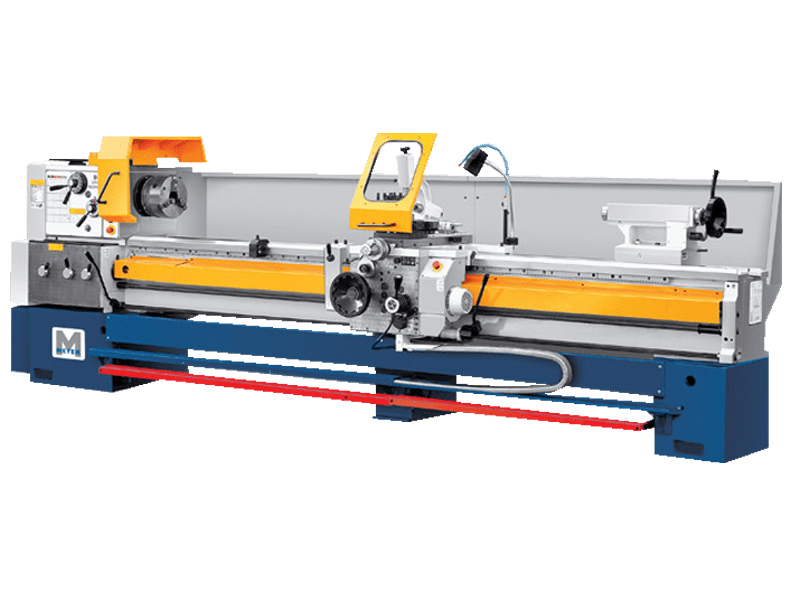

Meyer Euroline ES Precision Centre Lathes

The Meyer Euro Line range of precision centre lathes are of robust construction and are designed and manufactured in Europe using high-quality materials and with stringent quality control procedures.

The ER and ES models span a range from a small tool room lathe with a 325mm swing over bed and 500mm between centres, up to a 600mm swing over bed with 5 metres between centres.

All models come with thread cutting as standard, offering a large range of metric, imperial, module, and diametric pitches. Many models can be supplied with an optional infinitely variable speed configuration, including a number of sub-ranges.

| ES 440/1000

ES 440/1500 ES 440/2000 ES 440/3000 ES 440/4000 ES 440/5000 |

ES 500/1000

ES 500/1500 ES 500/2000 ES 500/3000 ES 500/4000 ES 500/5000 |

ES 580/1000

ES 580/1500 ES 580/2000 ES 580/3000 ES 580/4000 ES 580/5000 |

ES 600/1000

ES 600/1500 ES 600/2000 ES 600/3000 ES 600/4000 ES 600/5000 |

||

| Capacities | |||||

| Height of centers | mm | 220 | 250 | 290 | 300 |

| Swing over Bed | mm | 440 | 500 | 580 | 600 |

| Swing over cross slide | mm | 240 | 300 | 380 | 400 |

| Swing in gap* | mm | 640 | 700 | 780 | 800 |

| Width of bed | mm | 400 | |||

| Distance between Centres | mm | 1000 – 1500 – 2000 – 3000 – 4000 – 5000 | |||

| Spindle | |||||

| Spindle nose DIN 55027 | No | 8 | |||

| Spindle bore | mm | 80 | |||

| Spindle taper | Metric | 80 | |||

| Headstock | |||||

| Number of spindle speeds | – | 21 | |||

| Spindle speed ranges | rpm | 20 – 2000 | |||

| Main motor power | kW | 7.5 (11) | |||

| Feeds | |||||

| Number of feeds | – | 120 | |||

| Longitudinal feed range | mm/rev | 0.04 – 12 | |||

| Cross feed range | mm/rev | 0.02 – 6 | |||

| Threads | |||||

| Number of threads | – | 64 of each kind | |||

| Metric thread range | mm | 0.5 – 120 | |||

| Inch thread range | Tpi | 60 – 1/4 | |||

| Module thread range | Module | 0.125 – 30 | |||

| DP thread range | DP | 240 – 1 | |||

| Carriage | |||||

| Cross slide travel | mm | 315 | |||

| Top slide travel | mm | 130 | |||

| Tailstock | |||||

| Quill diameter | mm | 90 | |||

| Quill taper | Morse | No.5 | |||

| Quill travel | mm | 230 | |||

| Dimensions | |||||

| Length | mm | 2900 – 6900 | 2900 – 6900 | 2900 – 6900 | 2900 – 6900 |

| Width | mm | 1100 | 1100 | 1100 | 1100 |

| Height | mm | 1700 | 1700 | 1800 | 1800 |

| Weight | kg | 2900 – 4120 | 2950 – 4200 | 3010 – 4270 | 3110 – 4320 |

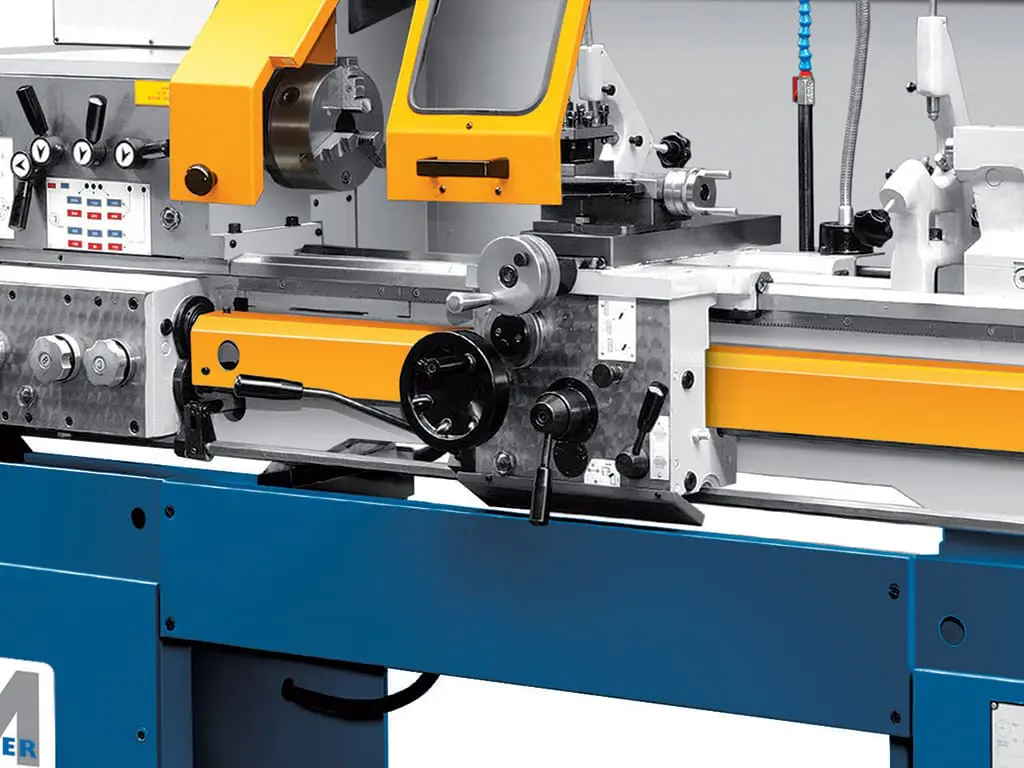

Features

- High quality European built machines

- Rigid build ensures high chip removal rate during the rough turning operation

- Highly resistant steel with high loading capacity used for all gear and spindle parts

- Cast bed with hardened and ground bed ways

- Four position square toolpost

- Chuck guard with interlock switch

- Lead screw guard

- Low voltage halogen work light

- Centralised lubrication

- Chip collection tray

- Coolant system

- Full length rear splash guard

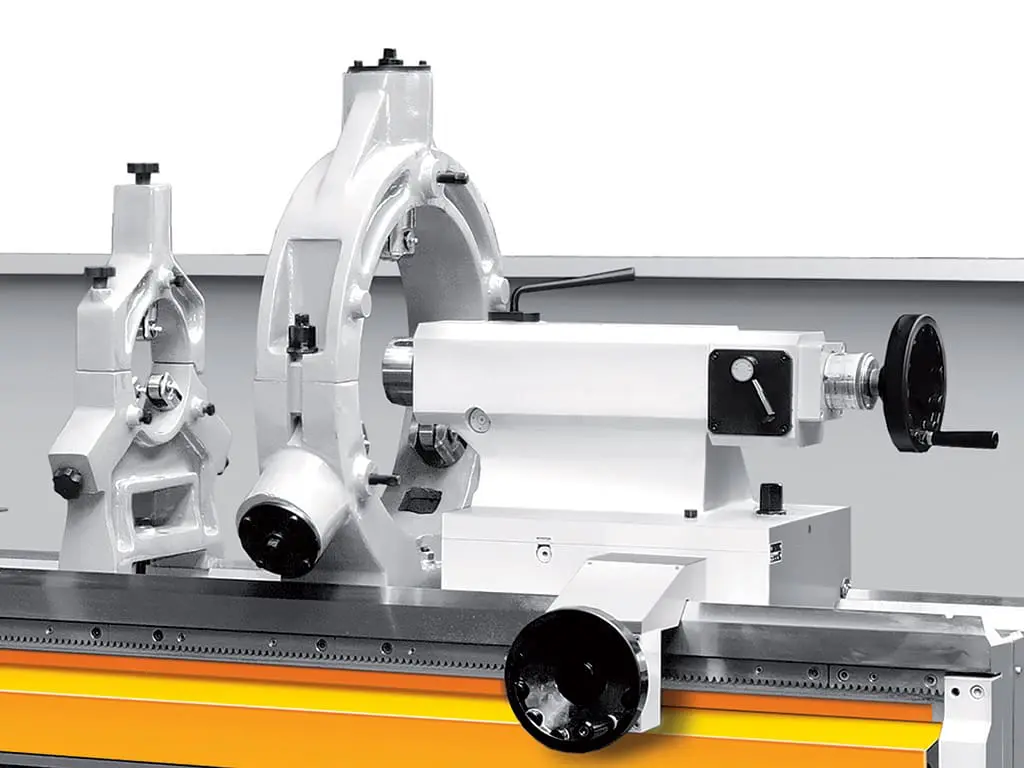

Options

- Variable spindle speed

- 2 or 3 axis digital read out

- Thread dial indicator

- Quick change tool post

- 3 and 4 jaw chucks

- Face plate

- Fixed steady

- Follow rest

Meyer Euroline ES Precision Centre Lathes: Robust, Versatile, and Built for Excellence

The Meyer Euroline ES Precision Centre Lathes represent the pinnacle of European engineering, combining robust construction with meticulous craftsmanship. Designed and manufactured in Europe using high-quality materials and rigorous quality control processes, these lathes deliver exceptional performance and durability. Whether you’re working on small, intricate parts or large, demanding projects, the Meyer Euroline ES series offers the precision, versatility, and reliability that modern workshops and production facilities require.

Comprehensive Range for Diverse Applications

The Meyer Euroline ER and ES models are available in a wide range of sizes to accommodate diverse industrial needs. The lineup begins with a compact toolroom lathe, featuring a 325mm swing over bed and 500mm between centres, ideal for smaller, precision-focused tasks. At the larger end of the spectrum, the range includes models with a 600mm swing over bed and 5 metres between centres, capable of handling substantial components for heavy-duty applications. This versatility ensures the Meyer Euroline ES series can meet the needs of a variety of industries, from general engineering to specialised manufacturing.

Thread Cutting Capabilities

A standout feature of the Meyer Euroline ES lathes is their comprehensive thread cutting functionality, which comes as standard across all models. These machines offer a wide range of threading options, including:

- Metric threads for European standards.

- Imperial threads for compatibility with legacy systems.

- Module threads commonly used in gear manufacturing.

- Diametric threads for specialised applications.

This extensive threading capability makes the Meyer Euroline ES series an excellent choice for workshops that require flexibility and precision when working with different standards and specifications.

Infinitely Variable Speed for Enhanced Control

Many models in the Meyer Euroline ES range can be equipped with an optional infinitely variable speed configuration. This advanced feature allows operators to make precise adjustments to the spindle speed, enabling optimal performance for various materials and cutting conditions. The variable speed system also includes multiple sub-ranges, giving users greater control over the lathe’s performance. This level of customisation ensures that the machine can adapt seamlessly to the demands of both intricate precision work and high-torque heavy-duty operations.

Built for Durability and Stability

The robust construction of the Meyer Euroline ES lathes ensures long-term reliability and stability, even under demanding conditions. The rigid bed design minimises vibration during operation, which not only enhances the quality of the finished workpiece but also reduces wear on the cutting tools. The use of high-quality European materials further reinforces the machine’s durability, ensuring consistent performance over years of heavy use. For workshops that prioritise dependability and low maintenance, the Meyer Euroline ES lathes are a sound investment.

User-Friendly Features for Improved Productivity

The Meyer Euroline ES series is designed with operator convenience in mind. Key features include:

- Ergonomic controls: Positioned for ease of use and quick adjustments.

- Clear displays: Provide accurate information for precise operations.

- Smooth operation: Advanced mechanisms reduce noise and friction for a more comfortable working environment.

These user-friendly features reduce the learning curve for new operators and improve productivity by enabling experienced machinists to work more efficiently.

Versatility Across Industries

The flexibility and precision of the Meyer Euroline ES lathes make them suitable for a wide range of applications across various industries, including:

- General engineering: Producing components for machinery and equipment.

- Aerospace: Machining high-precision parts for aircraft.

- Automotive: Creating engine components and specialised parts.

- Toolmaking: Crafting custom tools and dies.

This versatility ensures that the Meyer Euroline ES series can meet the needs of both small workshops and large manufacturing facilities, making it a valuable addition to any machining operation.

Optional Upgrades and Accessories

To further enhance their functionality, the Meyer Euroline ES lathes can be customised with a range of optional upgrades and accessories. These include:

- Digital readouts (DRO) for precise measurement and ease of operation.

- Steady rests and follow rests for added support when machining long or thin workpieces.

- Quick-change tool posts for efficient tool setup and switching.

- Coolant systems to improve cutting performance and prolong tool life.

These optional features allow businesses to tailor their lathes to specific requirements, ensuring maximum productivity and versatility.

Precision Meets Performance

The Meyer Euroline ES Precision Centre Lathes are engineered to deliver exceptional performance and consistent results. With their advanced features, robust construction, and wide range of capabilities, these lathes provide a reliable solution for precision machining. The inclusion of thread cutting as standard, along with optional variable speed configurations, ensures that these machines can handle a diverse array of tasks with ease and efficiency.

Conclusion: A Trusted Choice for Modern Workshops

In summary, the Meyer Euroline ES Precision Centre Lathes are a testament to European engineering excellence. Offering a combination of precision, durability, and user-friendly features, they are designed to meet the demands of modern workshops and production facilities. Whether your focus is on small, intricate parts or large, heavy-duty projects, the Meyer Euroline ES series provides the tools needed to achieve superior results. With a range of sizes, advanced options, and a reputation for quality, these lathes are an investment in performance and reliability that will serve businesses well for years to come.