Choosing the Right Machine for Your Workshop

Investing in a tube or section laser is a big decision — and the right choice depends entirely on the type of work you do, the materials you process, the volume you handle and the space you have available. At Selmach, we offer five distinct models, each designed to excel in a different kind of fabrication environment.

This guide breaks down the strengths and considerations of each machine to help you decide which one fits your workflow best.

The models we’ll cover are:

Quick Overview: What Each Machine Does Best

| Machine Model | Ideal For | Things to Consider |

|---|---|---|

| RVD SmartFibre TFC | Small–medium workshops, tight floor space, small/medium tubes & sections. | Limited heavy-section capacity; not for very long or heavy profiles. |

| RVD SmartFibre TFL | Mixed profile cutting: tube, box, angle, channel, section. | Mid-size footprint; not as fast as high-production models. |

| RVD SmartFibre TF | High-volume tube cutting, batch runs, repeat production. | Larger footprint; focused on high-volume production. |

| Morgan Rushworth XTR | Heavy-duty structural tube & section work; large or thick profiles. | Largest footprint; highest investment level. |

| RVD SmartFibre PRT | Workshops needing both sheet and tube cutting capability in one machine. | More complex workflow; may not match dedicated machines in extreme workloads. |

Detailed Comparison: Which Machine Fits Your Work?

1. RVD Smartfibre TFC – Compact Tube Laser

The TFC is designed for workshops where space is limited but precision and flexibility still matter. It’s compact, efficient and excellent for everyday tube and small-section work.

Best For:

-

Small to medium fabrication shops

-

Mixed small-batch work

-

Workshops with restricted floor space

-

Architectural metalwork, handrails, furniture frames, bespoke jobs

Pros:

-

Very compact footprint

-

Flexible loading options (semi-auto or bundle loading)

-

Ideal for small/medium tubes and sections

-

Lower installation and space costs

Cons:

-

Not intended for extremely heavy or oversized structural sections

-

Less suited to very high-volume production

2. RVD SmartFibre TFL – Tube & Section Laser

A versatile machine designed for workshops that need to cut both tube and structural sections. It’s a step up in capability from the TFC and suited to a wider range of profiles.

Best For:

-

Fabricators handling tube, box section, angle, channel and light structural sections

-

Workshops needing more versatility than a simple tube-only laser

-

Medium-volume production environments

Pros:

-

Handles both tubes and open sections

-

Strong all-rounder for varied workloads

-

Good combination of capacity and flexibility

Cons:

-

Larger footprint than the TFC

-

Not as fast as high-production models for pure tube work

3. RVD SmartFibre TF – High-Production Tube Laser

The TF is built for speed and volume. If your business revolves around producing large numbers of tube components, this machine keeps throughput high and downtime low.

Best For:

-

Large batch runs

-

Repeated tube-only production

-

Manufacturers with tight turnaround requirements

Pros:

-

High-speed processing for volume production

-

Excellent repeatability and low cycle times

-

Ideal for continuous, predictable tube workflows

Cons:

-

Larger footprint and higher investment

-

Focused on tube work rather than a wide mix of profile types

4. Morgan Rushworth XTR – Heavy-Duty Tube Laser

The XTR is the powerhouse of the range. It’s designed for large, heavy, thick-wall and long-profile work where robustness and power matter most.

Best For:

-

Structural steel fabricators

-

Heavy engineering workshops

-

Large industrial components

-

Thick-walled or oversized tubes and sections

Pros:

-

Highest capacity across the range

-

Ideal for heavy-duty and large-format fabrication

-

Very strong, rigid construction for demanding jobs

Cons:

-

Requires the most space

-

Higher investment and running requirements

-

Overkill for smaller or lightweight work

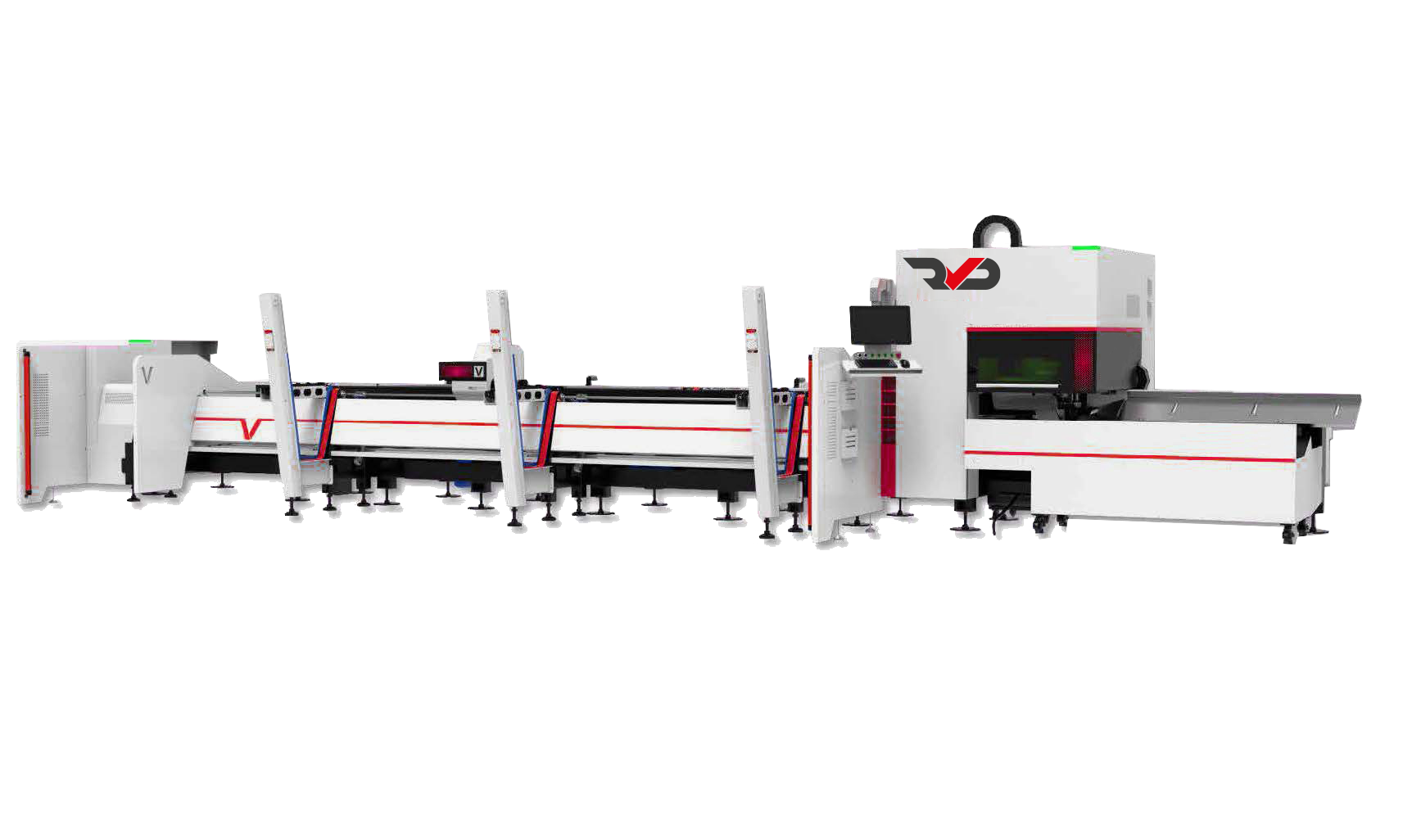

5. RVD SmartFibre PRT – Combination Sheet / Tube Laser

The PRT is a hybrid solution for workshops that need to cut both sheet metal and tube/section profiles. If your work is varied, this machine offers an efficient multi-purpose approach.

Best For:

-

General fabrication shops

-

Businesses doing both sheet and tube work

-

Custom metalwork, prototypes, mixed-batch environments

Pros:

-

Cuts both sheet and tube in one machine

-

Saves space compared with owning two separate systems

-

Excellent flexibility for changing workloads

Cons:

-

Not as specialised as dedicated tube-only or sheet-only machines

-

More setup changes for mixed workflows

How to Choose the Right Machine

Ask yourself the following:

1. What do you cut most often?

-

Small/medium tubes → TFC

-

Mixed tubes and sections → TFL

-

High-volume tube production → TF

-

Large structural profiles → XTR

-

Sheet + tube work together → PRT

2. How much space do you have?

-

Tight floor space → TFC or PRT

-

Mid-size shop → TFL or TF

-

Large open floor area → XTR

3. What’s your expected production volume?

-

Small batches / custom work → TFC or PRT

-

Mixed but steady workloads → TFL

-

High volume → TF

-

Industrial heavy fabrication → XTR

Final Thoughts

Each machine in our range is designed with a specific type of fabricator in mind. Whether you need compact precision, versatile profile cutting, high-speed production, heavy-duty capability or a flexible combination machine, there is a model that aligns with your workflow.

Choosing the right system means understanding your typical work, your available space, and how your production might change in the future. If you’d like help matching your requirements to the right machine, our team can guide you through the options.

Explore the full range of Tube & Section Fibre Laser Cutter machinery.

Published 5th December 2025

![Morgan Rushworth BLT Tube Laser [Web]](https://selmach.com/wp-content/smush-webp/2022/12/Morgan-Rushworth-BLT-Tube-Laser-Web.png.webp)