Automation in fabrication is no longer limited to complex robotic systems or fully unmanned factories. For many manufacturers, automation starts with simple, intelligent features that reduce manual effort, speed up everyday processes, and improve consistency across the workshop by removing human error.

This page explores automation as a progression — from basic time-saving machine functions, through semi-automatic and CNC-controlled equipment, to fully integrated loading systems and continuous production lines. Each step is designed to increase productivity, reduce handling, and make better use of both machinery and skilled operators.

Whether the goal is to free up operator time, improve repeatability, increase throughput, or move towards lights-out manufacturing, automation can be introduced in stages that suit your production demands, floor space, and budget.

Explore automation solutions by level of complexity and investment

For reducing manual handling and speeding up everyday workshop tasks.

For increasing throughput with controlled, repeatable machine movements.

For programmed accuracy, flexibility and repeatable production.

For continuous operation, lights-out manufacturing and maximum utilisation.

Simple Automation for Faster, Smoother Workflows

Automation doesn’t always mean complex systems or fully robotic lines. Often, the biggest gains come from small, clever features built into everyday workshop machinery. These tools free operators from repetitive tasks, improve consistency, and keep production moving with less manual intervention.

Across our range, several machines already deliver this kind of “hands-light” automation:

Gravity Down-Feed Bandsaws

Our Bianco and Sterling manual bandsaws use a controlled gravity down-feed system, allowing you to start the cut and step away to tackle the next task. The saw maintains a steady, consistent feed rate on its own, saving operator time while ensuring a clean, predictable finish.

Automatic Feed on Pillar Drills

Selected Meyer pillar drills incorporate an automatic feed for drilling and tapping. Once the operation begins, the machine drives the tool through the material at a precise rate, achieving repeatable accuracy with minimal operator input. It’s an easy way to boost throughput and reduce fatigue on long drilling runs.

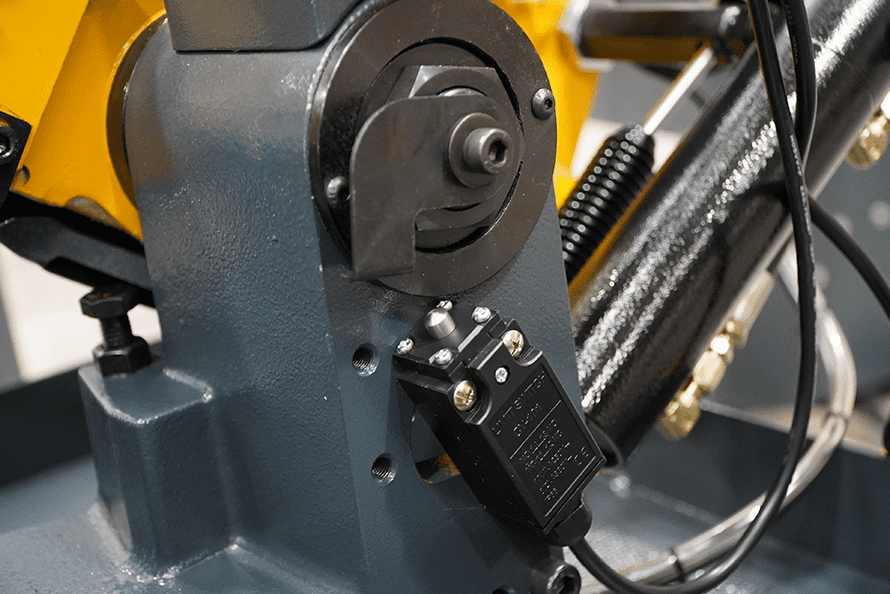

Touch-and-Cut Steelworker Shearing

Among their numerous capabilities, Morgan Rushworth Steelworkers feature a touch-and-cut system on the shear station. When the material reaches the pre-set length, the sensor triggers the cut automatically. It removes the need for manual measurement and timing, giving faster, more consistent shearing across batches.

PEHU Measuring Systems

The manual PEHU stop and measuring systems replace tape measures and manual marking with a fast, reliable length-setting solution for bandsaws and circular saws. Operators simply position the material against the stop and cut — reducing errors, setup time, and wasted material.

Semi-Automatic Automation for Higher Throughput

Semi-Automatic Bandsaws

Semi-automatic bandsaws amongst, other features, automate the return of the saw bow once a cut is completed. The operator initiates the cut, and the machine handles the return stroke automatically, reducing idle time between cuts. This is particularly effective when cutting multiple lengths from bar, tube or section, allowing faster repetition without compromising cut quality.

PEHU Automatic Measuring & Feeding Systems

PEHU measuring systems with integrated material feed, such as the LMS 30, take accuracy and speed a step further. Once the required length is set, the system automatically positions the material ready for cutting. This removes manual pushing, measuring and repositioning, delivering consistent lengths across batches while significantly improving cutting efficiency.

Precision Drilling & Tapping Machines

Drilling and tapping machines provide controlled, repeatable tapping depth and alignment. By guiding the tool squarely into the workpiece and maintaining consistent pressure, these machines reduce broken taps, improve thread quality, and speed up repetitive tapping operations — particularly valuable in fabrication and maintenance environments.

NC-Controlled Horizontal Bending

Horizontal bending machines fitted with an NC control and backgauge system allows for precise, repeatable bends with minimal setup time. Once programmed, the machine positions the material accurately for each bend, ensuring consistency across single parts or full production runs. This level of control reduces rework, speeds up bending operations, and supports more complex component production.

Fully Automated CNC-Controlled Machinery

At this stage, automation moves beyond individual assisted actions and into fully programmed processes. CNC and PLC-controlled machines allow complex operations to be repeated with speed, accuracy and consistency, reducing set-up time while increasing output across batch and multi-part production.

Automatic Bandsaws with PLC or CNC Control

Automatic bandsaws equipped with PLC or CNC controllers handle the entire cutting cycle without manual intervention. PLC-controlled saws excel at high-volume production of identical lengths, making them ideal for stock preparation and batch cutting. CNC-controlled bandsaws go further, allowing multiple lengths, angles and cutting sequences to be programmed into a single job — perfect for complex profiles and mixed production runs.

CNC Box & Pan Folders

CNC box and pan folders automate the folding process with programmable bending sequences and precise control of blade movement. Once the programme is set, the machine repeats folds accurately across enclosures, panels and box sections, delivering consistent results while dramatically reducing setup and handling time.

CNC Press Brakes

CNC Press Brakes bring precision, flexibility and repeatability to bending operations. With programmable backgauges, bend sequences and tooling configurations, operators can move quickly between jobs while maintaining tight tolerances. This level of control supports everything from single-part prototypes to high-volume production runs.

CNC Profiling Machines

CNC profiling machines, including laser, plasma and waterjet cutting systems, deliver high-speed, high-accuracy cutting across a wide range of materials and thicknesses. Once programmed, they handle complex shapes and nested parts with minimal operator input, improving material utilisation and ensuring consistent quality from the first cut to the last.

Automated Loading Systems & Integrated Production Lines

Automated Loading for Tube & Section Lasers

Tube and section laser systems can be fitted with automated loading solutions such as bundle loading or magazine loading. These systems feed tubes and sections into the machine automatically, maintaining a steady flow of material without manual lifting or repositioning. The result is higher productivity, improved safety, and consistent cutting performance across long production runs.

Sheet Metal Laser Tower Systems

Automated tower systems for fibre laser cutting machines take productivity to another level. Multiple material pallets are stored, loaded and unloaded automatically, allowing the laser to run continuously. These systems are ideal for lights-out manufacturing, where material is loaded before the end of the shift and the machine continues cutting unattended overnight, maximising machine utilisation and return on investment.

Cut-to-Length (CTL) Production Lines

Cut-to-length lines (or Coil Processing & Shearing Systems) integrate multiple machines — such as presses, guillotines, punches and straighteners — into a single, continuous production system. Starting from coil stock, material is processed, cut and finished automatically into ready-to-use components. Each line can be configured to suit your specific production requirements, delivering a fully automated workflow from raw material to finished product.

Why Choose Selmach for Automation Solutions?

Automation is most effective when it’s applied with a clear understanding of real-world manufacturing. Selmach focuses on practical, proven automation that delivers measurable improvements in productivity, accuracy and workflow, without unnecessary complexity.

We offer automation at every level, from simple time-saving machine features through to fully integrated, lights-out production systems. This allows automation to be introduced in stages, aligned to your production demands, floor space and budget, rather than forcing a one-size-fits-all solution.

Our approach is built around understanding your process first. By assessing how material moves through your workshop, we can recommend machinery and automation that genuinely removes bottlenecks, reduces handling and improves throughput.

With a broad portfolio of machinery, in-house technical expertise and ongoing support, Selmach provides automation solutions that are engineered to work reliably in demanding production environments; today and as your business grows.

Speak to a Specialist

Tell us about the processes you’re looking to improve — we’ll recommend the machinery combination that best supports your workload and growth plans.

Looking for something bespoke? We can work with you to deliver an entirely bespoke solution, no matter what machinery or processes you need to consider.