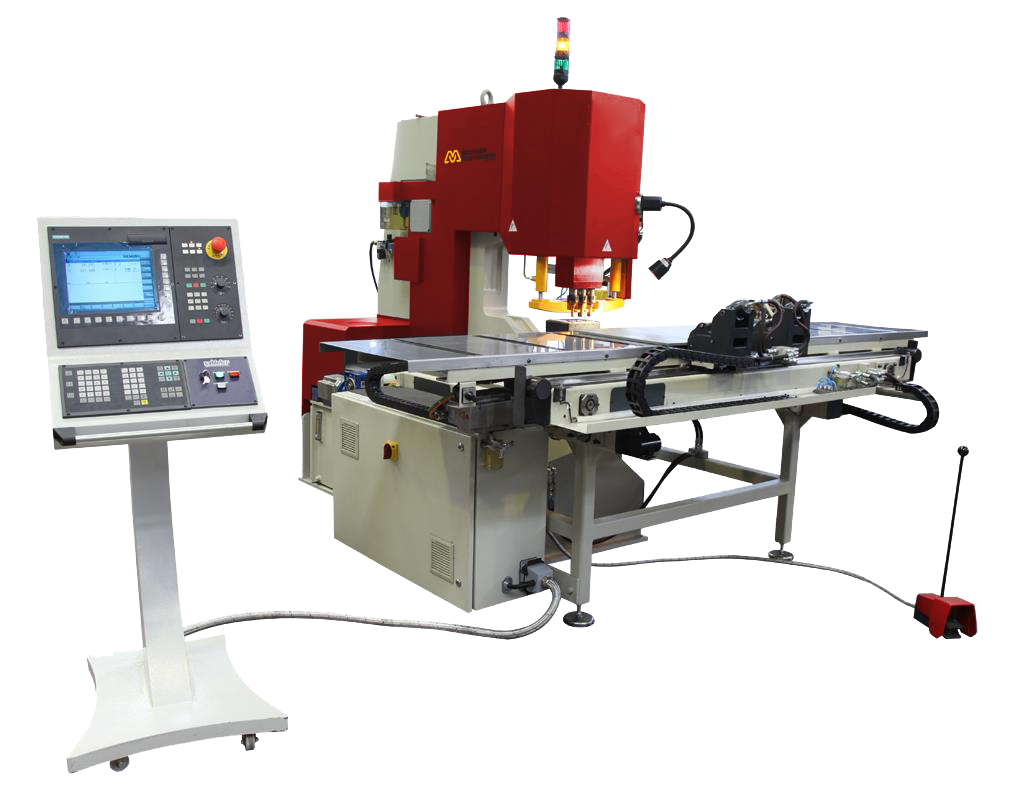

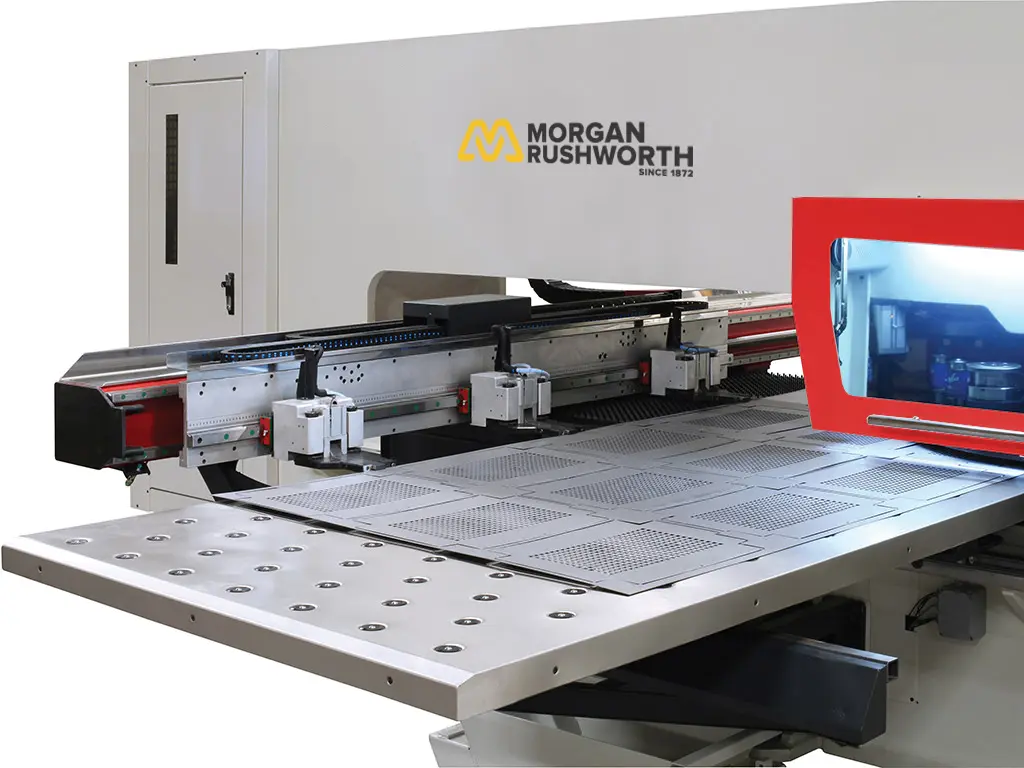

CNC Turret Punch Press Machines UK

At Morgan Rushworth, turret punch presses are supplied as production machines rather than entry equipment. Rigid frames, precision indexing systems and modern CNC control platforms allow consistent accuracy at high stroke rates, making them suited to both batch manufacturing and repeat production. Components can be produced complete with countersinks, louvres, extrusions and forming features; often ready for bending straight off the machine.

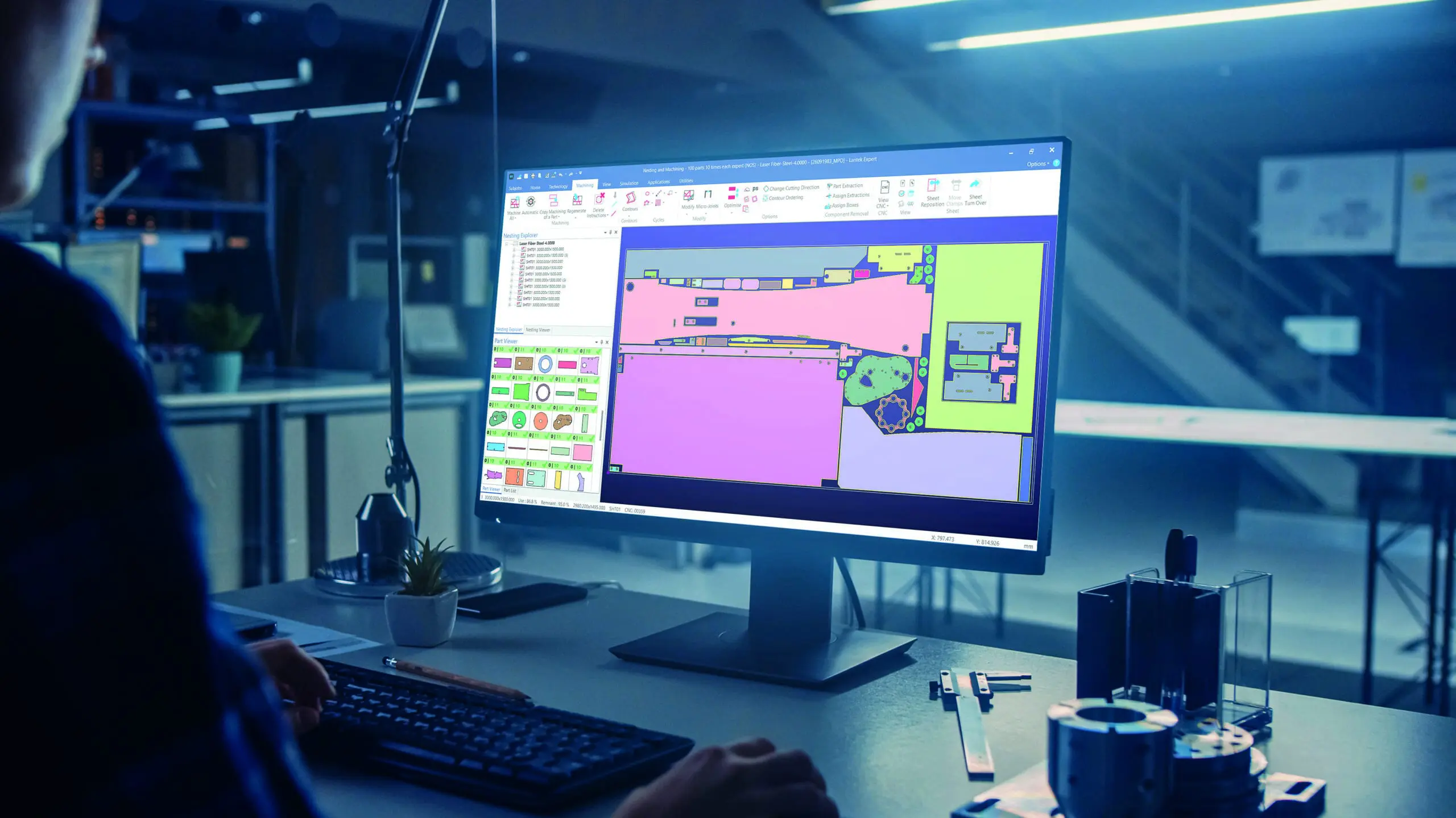

When paired with modern nesting software, material utilisation improves dramatically. Parts are arranged automatically across the sheet, scrap is reduced and repeat jobs become essentially a load-and-run operation. For many manufacturers this becomes the bridge between manual fabrication and full automation, increasing output without immediately requiring robotic handling.