Volumec Drilltronic Drilling & Tapping Machine

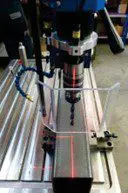

The Volumec Drilltronic is an advanced articulated arm drilling and tapping machine powered by a high-performance brushless motor. It offers versatility with the option to be supplied with a table or mounted on a floor stand. In its basic form, the machine is manually positioned, making it a practical solution for a range of tasks.

For enhanced precision, the optional Volumec Assisted Positioning System (VAPS) automatically locks the machine at programmed positions. VAPS allows simple programming of X and Y coordinates for square or rectangular parts, or diameter and angle settings for circular workpieces.

| MODEL | DT13100 | DTS161250 | DT134500 | |

| Drilling Speed Range | RPM | 100 – 1000 | 30 – 1250 | 125 – 4500 |

| Drilling Capacity with Twist Drill | mm | 3 – 13 | 3 – 16 | 3 – 10 |

| Maximum Drilling Capacity with Cutter | mm | 20 | 30 | 15 |

| Tapping Capacity | M3 – M12 | M3 – M20 | M3 – M8 | |

| Column Height | mm | 1060 | 1060 | 1060 |

| Maximum Height under Drilling Head | mm | 650 | 650 | 650 |

| Maximum Distance from Column to Spindle Centre | mm | 1300 | 1300 | 1300 |

Features

- Articulated arm drilling, tapping and countersinking

- Easy manual positioning

- High performance brushless motor

- Infinitely variable drilling speed

- Manual drilling feed

- Quick change tooling system

Options

- VAPS assisted control system

- VAPS-Z automated drilling on the Z axis

- Column for floor mounting

- Workbench with tee slots

- Spray mist coolant system

- Flood coolant system

- Laser pointer

- High precision depth sensor

- LED sensor for edge finding in stainless steel

DRILLTRONIC Drilling and Tapping Units

The DRILLTRONIC is a state-of-the-art integrated drilling and tapping unit, equipped with an innovative articulated arm system that offers maximum working flexibility. Its advanced design enables smooth and precise positioning, ensuring rigidity and precision throughout machining operations. This unique combination of flexibility and stability makes DRILLTRONIC a standout solution for modern machining needs.

Advanced Articulated Arm Technology

The articulated arm in the DRILLTRONIC provides unparalleled freedom of movement, enabling operators to position the unit quickly and effortlessly. This technology ensures accuracy and ease during operation, reducing setup time and improving overall efficiency. The sturdy structure and innovative design ensure the machine maintains its precision even during intensive use.

VAPS: Revolutionary Control System

The Volumec Assisted Positioning System (VAPS) revolutionises the drilling and tapping process. Featuring an intuitive touch-screen operator interface, VAPS allows for precise and straightforward programming of tasks without the need for manual tracking. The system provides operators with advanced functionality, enhancing both accuracy and productivity.

Key features of VAPS include:

- Quick Identification of Workpiece Solutions: Zero search for efficient setup.

- Assisted Tool Positioning: Automatic locking of the tool at the specified measurement on the work surface.

- Intuitive Programming: Easy input of multiple drilling points, including X, Y coordinates and tool diameter.

- Custom Drilling Cycles: Create and save drilling patterns for repeated use on various shapes.

- Automatic Flange Drilling: Automatically calculate drilling points based on the radius and angle between holes.

- Auto-Learning Mode: Program drilling tasks through automatic learning for enhanced efficiency.

- Automatic Threading: Set pitch and depth for threading tasks with ease.

- Manual Mode: Retain the flexibility to perform positioning and drilling manually.

- Program Import/Export: Transfer drilling programs via USB.

- LAN Connectivity: Connect to a PC using Ethernet for seamless program management.

Optional Features for Enhanced Functionality

To further extend its capabilities, the DRILLTRONIC offers a range of optional extras designed to enhance precision, usability, and efficiency:

- Automatic Lubrication System: Ensures optimal tool lubrication, improving performance and extending tool life.

- High Precision Laser Pointer System: Displays the exact drilling location before operation, reducing errors.

- Depth Sensor: Allows precise control of drilling, tapping, or countersinking depths.

- Refrigeration System: Features a powerful 22 l/min emulsion plant for effective cooling during extended operations.

- Workbenches: Designed specifically for the DRILLTRONIC, these workbenches feature a 30mm reinforced base and storage compartments. Available with rough or T-slot tops, they can also be configured for refrigeration systems.

- Ground Fixing Column: Provides a stable base for the DRILLTRONIC, allowing it to be securely fixed to the ground for maximum stability during operation.

Exceptional Flexibility and Precision

The DRILLTRONIC stands out for its ability to handle a wide range of tasks with unmatched precision. Operators can program and execute drilling, tapping, and countersinking operations with ease, thanks to the intuitive interface and advanced features. The auto-learning mode further simplifies complex tasks, making the machine suitable for both experienced and novice operators.

Applications Across Industries

The versatility of the DRILLTRONIC makes it ideal for various industrial applications, including automotive, aerospace, and general manufacturing. Its ability to perform precise drilling and tapping on multiple materials and workpieces ensures it can meet the demands of high-production environments and specialised tasks alike.

Benefits of an Integrated System

The integration of the articulated arm, VAPS, and optional features provides a comprehensive solution for modern machining requirements. By combining flexibility with precision, the DRILLTRONIC eliminates the need for multiple machines, reducing workspace requirements and operational costs. The ability to save and reuse programs enhances repeatability and efficiency, making it a valuable addition to any workshop.

Conclusion

The DRILLTRONIC drilling and tapping unit redefines what is possible in machining, offering a perfect blend of flexibility, precision, and efficiency. Its innovative articulated arm, advanced VAPS control system, and extensive optional features make it a versatile and reliable choice for workshops seeking to elevate their capabilities. Whether for routine tasks or complex operations, the DRILLTRONIC delivers consistent performance and exceptional results, solidifying its position as a leader in modern machining solutions.