| MODEL | BM18 | |

| Power | kw | 2.2 |

| Spindle speed (without load) | rpm | 1800-5850 |

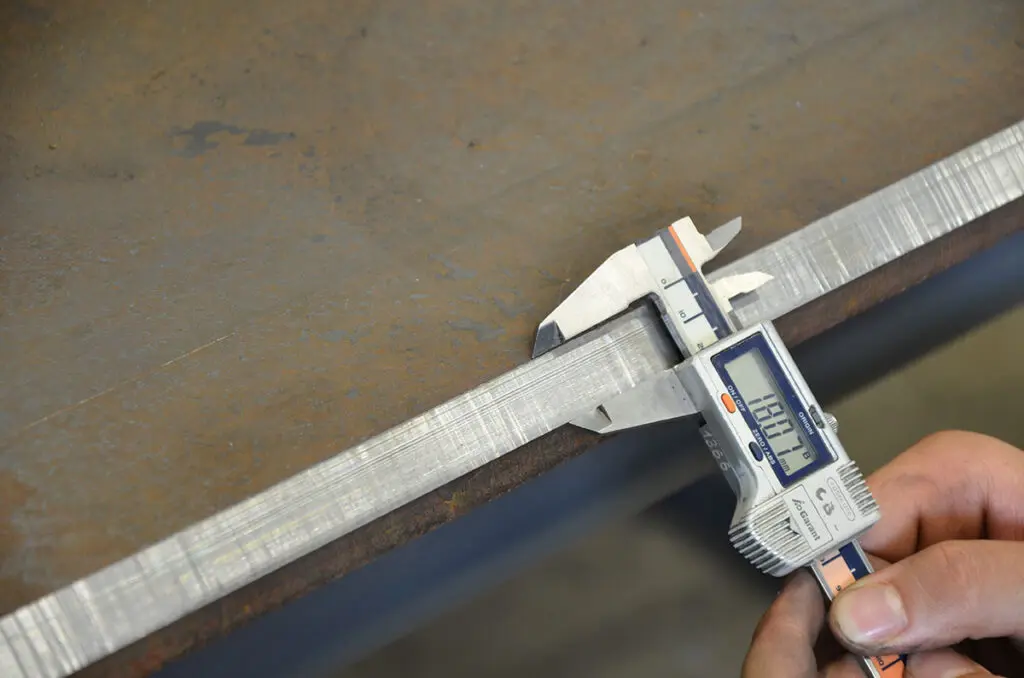

| Maximum bevel width | mm | 18 |

| Maximum bevel angle | ° | 60 |

| Minimum workpiece thickness | mm | 2 |

| Minumal diameter of countersinking | mm | 40 |

| Length | mm | 585 |

| Width | mm | 156 |

| Height | mm | 238 |

| Weight (without milling head) | kg | 12 |

Features

- increases durability more convenient assembly and disassembly of the milling head guiding roller is integrated with each milling head the clearance between milling head and guiding roller is precisely factory calibrated, thus requires no adjustment by the operator

- Powerful electric motor

- Maximum 18 mm bevel width (more than one pass could be required)

- Continuous bevel width adjustment

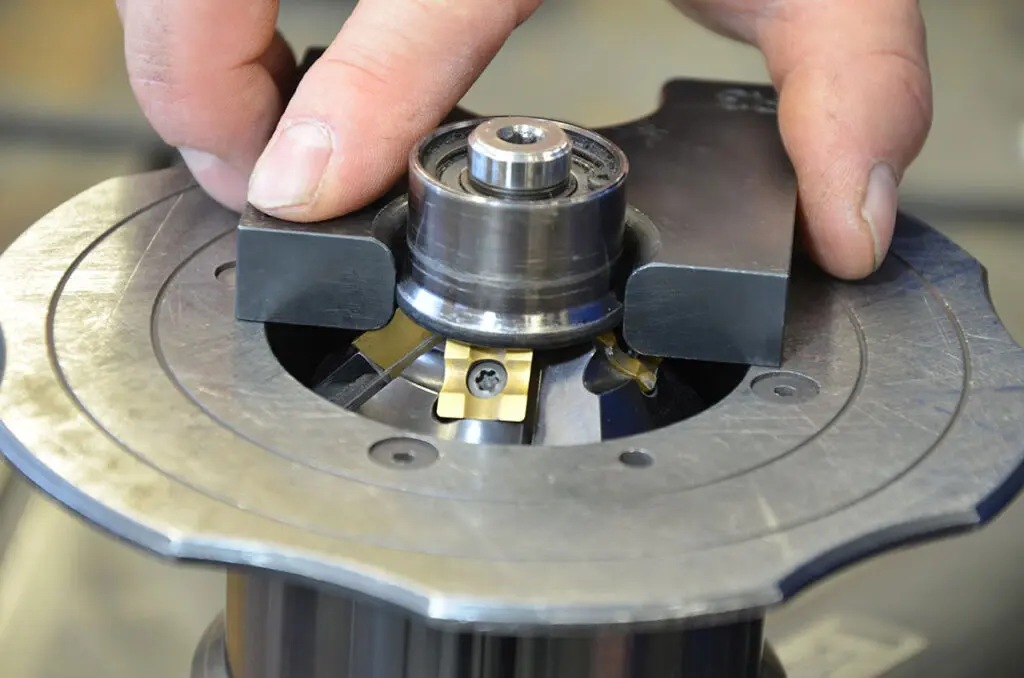

- New more durable milling heads with hexagonal fixing for easy replacement

- Electronic speed control between 1800–5850 rpm for use on a variety of materials

- Overload protection

- Bevelling milling head is equipped with 5 pcs of 2-sided indexable cutting inserts

- Milling head for rounding is equipped with 4 pcs of 4-sided indexable inserts up to R5

Options

- Milling head 20°

- Milling head 22.5°

- Milling head 27.5°

- Milling head 30°

- Milling head 37.5°

- Milling head 40°

- Milling head 45°

- Milling head 50°

- Milling head 55°

- Milling head 60°

- Milling head 65°

- Bevelling insert for steel (5 required)

- Bevelling insert for aluminium (5 required)

- Fixing screw for bevelling insert

- Radius milling head

- Radius insert R2 (4 required)

- Radius insert R3 (4 required)

- Radius insert R4 (4 required)

- Radius insert R5 (4 required)

- Fixing screw for radius insert

- Sticker against scratches, dedicated for aluminum bevelling. If the sticker is removed, clean excess glue from the guide using petroleum ether.

Introduction to the BM-18 Milling Machine

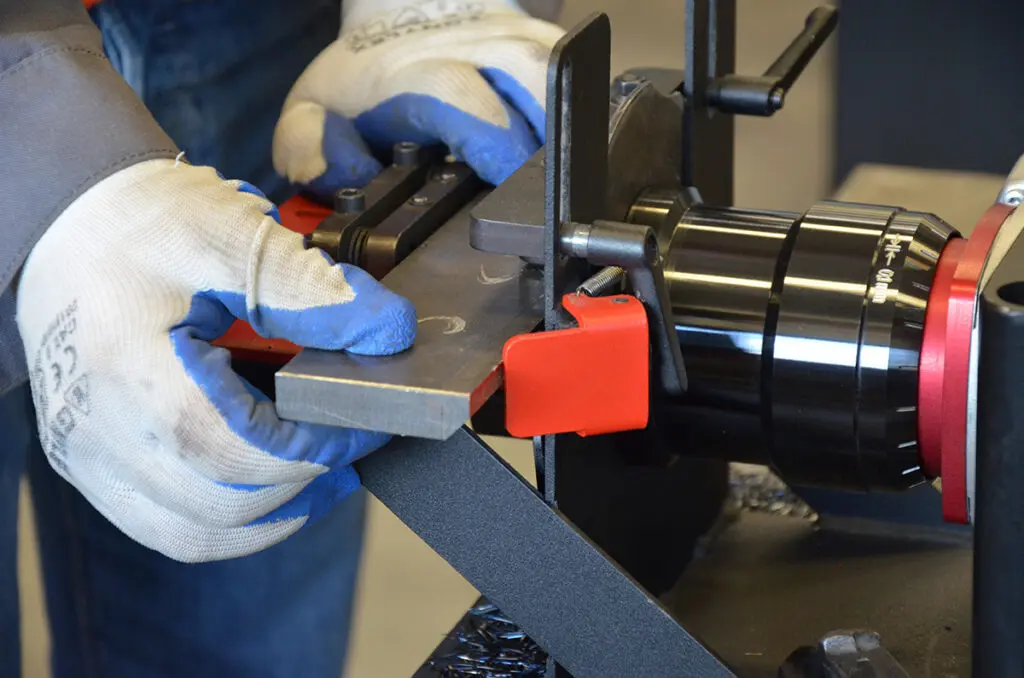

The BM-18 is a versatile and precise milling machine, designed to handle a wide range of bevelling and milling tasks. It is capable of milling straight edges up to an impressive 18 mm bevel width, while also excelling in contour milling and creating holes starting from 40 mm in diameter. This adaptability makes the BM-18 an essential tool for industries requiring reliable edge finishing and preparation for further processes such as painting or coating.

Whether used for rounding steel constructions to a radius of R2, R3, R4, or R5, or for other custom milling requirements, the BM-18 ensures exceptional performance and precision. Its innovative design and robust features cater to a variety of applications, from manufacturing plants to workshops focused on steel construction, aluminium fabrication, and plastic machining.

Key Features of the BM-18

Precise Milling Capabilities

The BM-18 is designed for high precision, making it suitable for detailed milling tasks. Its ability to handle bevel widths of up to 18 mm, as well as create smooth contours and accurately sized holes, provides a versatile solution for a variety of industries. The machine’s accuracy ensures optimal results in critical projects, where flawless edge preparation is crucial for subsequent steps such as welding, coating, or assembly.

Radius Rounding for Painting and Coating

A standout feature of the BM-18 is its capability to round off steel constructions to specific radii, including R2, R3, R4, and R5. This functionality is particularly beneficial in preparing materials for painting or coating, as rounded edges ensure better adhesion and a more uniform finish. By eliminating sharp corners and uneven surfaces, the BM-18 enhances the durability and aesthetic quality of coated materials.

Innovative Design and Enhanced Durability

Hexagonal Fixing for Milling Heads

The BM-18 incorporates a new hexagonal fixing system for its milling heads, a feature that significantly improves the machine’s durability and ease of use. This design not only enhances the overall strength and stability of the machine but also simplifies the process of replacing milling heads. Operators can now change heads quickly and efficiently, minimising downtime and improving productivity.

Built to Last

Constructed with durability in mind, the BM-18 is built to withstand the demands of intensive industrial use. Its robust design ensures consistent performance over time, reducing the need for frequent maintenance and repairs. This reliability makes it a cost-effective investment for businesses seeking long-term efficiency and performance.

Customisable Cutting for Various Materials

Variable Spindle Speed

The BM-18 is equipped with variable spindle speed, enabling users to tailor cutting conditions to the specific material being processed. This flexibility allows the machine to handle a wide range of materials, including stainless steel, aluminium, brass, and various alloys. By optimising the cutting speed, operators can achieve cleaner cuts, reduced wear on tooling, and improved overall efficiency.

Versatility in Material Processing

In addition to metals, the BM-18 is capable of working with non-metallic materials such as plastics. This versatility makes it a valuable tool for industries that deal with diverse material requirements, from heavy-duty steel construction to lightweight plastic components. Whether for industrial manufacturing, repair work, or prototype development, the BM-18 offers dependable performance across multiple material types.

Efficiency and Productivity

User-Friendly Operation

The BM-18 is designed with user convenience in mind. Its intuitive controls and ergonomic features make it accessible to operators of varying skill levels. By simplifying operation and setup, the machine reduces the learning curve, enabling businesses to maximise productivity without extensive training requirements.

Reduced Downtime

Thanks to its innovative features, such as the hexagonal fixing system and variable spindle speed, the BM-18 minimises downtime and ensures seamless operation. Quick head replacements and precise cutting adjustments contribute to a more streamlined workflow, allowing businesses to meet tight deadlines and maintain high standards of quality.

Applications of the BM-18

Steel Fabrication

The BM-18 is an invaluable tool for steel fabricators, enabling precise edge preparation and bevelling for welding, coating, and assembly tasks. Its ability to handle straight edges, contours, and holes ensures compatibility with a wide range of steel components, from structural beams to custom-fabricated parts.

Aluminium and Alloy Processing

For industries working with aluminium and other alloys, the BM-18 offers the precision and adaptability needed to meet exacting standards. Its variable spindle speed and radius rounding capabilities make it an excellent choice for preparing materials for automotive, aerospace, and architectural applications.

Plastic Manufacturing

The BM-18’s versatility extends to plastic manufacturing, where its precise milling and cutting capabilities ensure clean and accurate results. Whether working with lightweight components or intricate plastic parts, the machine delivers reliable performance.

Conclusion

The BM-18 milling machine is a powerful and versatile solution for industries requiring precision edge preparation and bevelling. Its innovative design, including a hexagonal fixing system for enhanced durability, variable spindle speed for customisable cutting, and capability to handle a wide range of materials, sets it apart from competitors.

Whether you are working with steel, alloys, aluminium, or plastic, the BM-18 delivers exceptional results with efficiency and ease of use. By investing in this advanced milling machine, businesses can streamline their workflows, improve productivity, and ensure high-quality outcomes for every project.