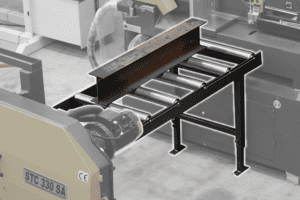

Narrow Gauge Roller Track System

Typically supplied with Sterling Aluminium Circular Saws, the powered heavy-duty roller track system is ideal for handling aluminium profiles and extrusions. Designed for efficiency, these robust tracks streamline material handling and ensure precise positioning during cutting operations.

Available in 2m lengths, they are perfectly suited for pairing with the SAR420 SA Aluminium Circular Saw. Their sturdy construction and seamless compatibility enhance workflow efficiency, making them an essential addition to workshops processing aluminium materials.

Typically supplied as a 300mm wide, 2m length.

Features

- Closed Rollers for small piece cutting

- Adjustable Height (mm – mm)

Options

Powered Heavy-Duty Roller Track System: Optimised Material Handling for Aluminium Profiles and Extrusions

The powered heavy-duty roller track system is a versatile and robust solution for efficient handling of aluminium profiles and extrusions. Specifically designed to pair with Sterling Aluminium Circular Saws, such as the SAR420 SA, these roller tracks streamline material handling, improve accuracy, and enhance overall workflow efficiency. With a 2m length as standard, they provide reliable support and are built to handle the demands of modern workshops processing aluminium materials.

Ideal for Aluminium Profiles and Extrusions

When working with aluminium profiles and extrusions, precise handling is crucial for achieving clean, accurate cuts. The powered heavy-duty roller track system is engineered to meet these needs, ensuring smooth and stable material movement. By reducing manual intervention, these tracks make it easier to process lightweight but often awkwardly shaped materials, improving both safety and productivity.

Seamless Integration with Sterling Aluminium Circular Saws

One of the standout features of this roller track system is its seamless compatibility with Sterling Aluminium Circular Saws, such as the SAR420 SA. Designed to integrate effortlessly, these tracks align perfectly with the saw, ensuring smooth material feeding and efficient outfeed. The system enhances the cutting process, allowing operators to focus on achieving precise results while the track handles the heavy lifting.

Modular and Customisable Design

The powered heavy-duty roller track system is supplied in 2m lengths, making it suitable for a range of workshop layouts. Its modular design allows multiple sections to be connected, enabling the creation of customised infeed and outfeed solutions tailored to your operational requirements. Additionally, the track can be adjusted to match the specific dimensions of your saw, ensuring optimal performance and ease of use.

Built for Durability and Performance

Constructed with high-quality materials, the roller track system is designed to withstand the rigours of daily workshop use. The durable rollers provide smooth material movement while reducing wear and tear, ensuring long-term reliability. This robust construction makes the system capable of handling a variety of aluminium profiles and extrusions without compromising performance.

Enhancing Workflow Efficiency

Automation is key to improving efficiency in modern workshops, and the powered heavy-duty roller track system delivers just that. By automating the movement of materials, the system reduces manual handling and minimises downtime, allowing operators to process more in less time. Whether used for feeding materials into the saw or transporting them to the next stage of production, this roller track system optimises workflow and ensures a steady pace of operations.

Applications Across Industries

The versatility of the powered heavy-duty roller track system makes it suitable for a wide range of industries. From manufacturing and construction to metal fabrication, this system is ideal for businesses that work with aluminium profiles, extrusions, and similar materials. Its ability to handle diverse shapes and sizes ensures that it meets the needs of various applications, from producing architectural components to cutting materials for industrial use.

Improving Workshop Safety

Manual handling of aluminium profiles and extrusions can be both time-consuming and risky, particularly in high-volume operations. The powered roller track system reduces the need for manual effort, minimising the risk of workplace injuries. By automating material movement, the system ensures controlled and precise handling, enhancing safety for operators and creating a more efficient working environment.

Low Maintenance and Cost-Effective

Designed for long-term use, the powered heavy-duty roller track system requires minimal maintenance. Its durable construction and reliable components reduce the need for frequent repairs, ensuring consistent performance over time. This low-maintenance design makes it a cost-effective investment for workshops looking to enhance their material handling capabilities without incurring significant upkeep costs.

Bespoke Options for Specialised Needs

While the standard 2m roller track system is suitable for most workshops, Selmach Machinery also offers bespoke options to meet specialised requirements. Whether you need longer tracks, custom widths, or additional features to handle unique materials, our team can design and deliver a tailored solution that maximises your operational efficiency.

Backed by Selmach Machinery Expertise

When you invest in the powered heavy-duty roller track system, you gain more than just a high-quality product – you benefit from Selmach Machinery’s extensive experience and commitment to customer satisfaction. Our team works closely with you to understand your needs, providing expert advice, customisation options, and ongoing support to ensure that your investment delivers long-term value.

Conclusion: A Reliable Solution for Aluminium Handling

The powered heavy-duty roller track system is an indispensable tool for workshops processing aluminium profiles and extrusions. With its robust construction, seamless integration with Sterling Aluminium Circular Saws, and ability to optimise workflows, it enhances productivity, safety, and efficiency. Whether used as a standalone system or part of a customised setup, this roller track delivers consistent performance and reliability.

For tailored solutions or more information on how the powered heavy-duty roller track system can transform your workshop operations, contact Selmach Machinery today. Let us help you optimise your material handling processes and achieve greater success in your production tasks.