Morgan Rushworth HFA (250 x 6) Hydraulic Corner Notching Machine

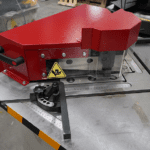

The Morgan Rushworth HFA (250 x 6) Hydraulic Corner Notching Machine is engineered for precise and reliable corner notching, offering a cutting capacity of 250mm x 6mm at a fixed 90° angle. Its robust design, featuring a rigid head and GS500 cast iron workbench, ensures exceptional stability and accuracy during operation.

Built for durability and longevity, the HFA corner notcher is ideal for demanding fabrication tasks. Its high-quality construction provides consistent performance, making it a reliable and cost-effective choice for workshops and industrial applications.

| MODEL | STOCKCODE | BLADE ANGLE | CUTTING LENGTH | CUTTING CAPACITY | CUTTING CAPACITY | MOTOR | STROKES PER MINUTE | WORK TABLE | LENGTH | WIDTH | HEIGHT | WEIGHT |

| mm | mm | M/Steel mm | S/Steel mm | Kw | mm | mm | mm | mm | kg | |||

| HFA 250/6 | M4000 | 90° | 250 | 6 | 3 | 4 | 25 | 800 x 750 | 1010 | 850 | 1400 | 630 |

Features

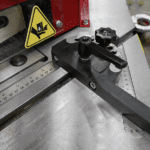

- Rigid head and workbench with conical grooves for optimal adherence of the squares.

- Cut can start from top of blades or from the base.

- Set of goniometric squares.

Options

- Stainless steel cutting blades.

Morgan Rushworth HFA (250 x 6) Hydraulic Corner Notching Machine

The Morgan Rushworth HFA (250 x 6) Hydraulic Corner Notching Machine is a high-performance tool designed for precise and reliable corner notching in industrial applications. With a cutting capacity of 250mm x 6mm at a fixed 90-degree angle, this machine delivers clean and accurate results across a range of materials. Engineered with durability in mind, the HFA notcher is built to withstand the demands of heavy-duty fabrication environments.

Its robust design, featuring a GS500 cast iron workbench and rigid head, ensures consistent performance and long service life, making it an excellent choice for industrial workshops.

Precision Cutting for Industrial Applications

The HFA Hydraulic Corner Notching Machine is built to deliver precise and consistent cuts, essential for professional fabrication work. Its fixed 90-degree angle provides reliability without the need for adjustments, enabling operators to maintain accuracy throughout the process.

With a cutting capacity of 250mm x 6mm, this machine is suitable for various materials, including mild steel and stainless steel. Its ability to produce clean notches makes it an ideal solution for structural and assembly applications across multiple industries.

Durable Construction for Demanding Workloads

The HFA notcher’s GS500 cast iron workbench provides exceptional stability during operation, minimising vibrations and ensuring precise cuts. The cast iron construction contributes to the machine’s durability, enabling it to handle high workloads in demanding industrial settings.

The rigid head enhances reliability by maintaining alignment during cutting, ensuring consistent results. These features make the HFA corner notcher a dependable tool for businesses requiring robust and long-lasting equipment.

High Productivity and Efficiency

The Morgan Rushworth HFA is designed to enhance productivity through its efficient and user-friendly features. Its fixed cutting angle streamlines the notching process, allowing operators to complete tasks quickly and accurately without frequent recalibrations.

The machine’s consistent performance ensures that even high-volume operations can be handled with ease, making it a valuable asset for increasing overall output in professional workshops.

Versatile Applications Across Industries

The HFA (250 x 6) Hydraulic Corner Notching Machine is engineered to meet the needs of a wide range of industries, including:

- Metal Fabrication: Precise notching for components and assemblies.

- Construction: Preparing structural steel components for infrastructure projects.

- Automotive Manufacturing: Producing accurate notches for vehicle parts and assemblies.

- Industrial Fabrication: Handling various materials for professional manufacturing processes.

Its versatility ensures that the HFA notcher can address diverse requirements, making it a valuable tool for industrial applications.

Ease of Use and Low Maintenance

The HFA corner notcher is designed for straightforward operation, allowing professionals to achieve accurate results with minimal effort. Its fixed 90-degree angle eliminates the need for complex setup or adjustments, ensuring a smooth workflow.

The machine’s durable construction reduces maintenance requirements, allowing for longer intervals between servicing. This minimises downtime and ensures that the HFA remains operational, providing a cost-effective solution for professional environments.

Safety Features

The Morgan Rushworth HFA notcher is equipped with features that prioritise operator safety. The GS500 cast iron workbench provides a stable and secure cutting surface, reducing the risk of movement or instability during operation.

Additionally, the rigid head and robust design contribute to a safe working environment by maintaining alignment and stability throughout the cutting process. These safety-focused elements ensure reliability and protection for operators in professional settings.

Cost-Effective and Reliable

The HFA (250 x 6) Hydraulic Corner Notching Machine offers an efficient and cost-effective solution for professional fabrication needs. Its durable construction, low maintenance requirements, and reliable performance reduce operational costs, making it a smart investment for industrial businesses.

By combining precision, efficiency, and durability, the HFA delivers consistent results, helping businesses optimise productivity and maintain high-quality standards in their operations.

Conclusion

The Morgan Rushworth HFA (250 x 6) Hydraulic Corner Notching Machine is a professional-grade tool designed to meet the needs of modern industrial environments. With its fixed 90-degree cutting angle, 250mm x 6mm capacity, and robust construction, this machine ensures precise and reliable performance across a variety of applications.

Its GS500 cast iron workbench and rigid head provide stability and durability, enabling consistent results in demanding fabrication tasks. For businesses seeking a dependable and efficient corner notching solution, the HFA notcher offers exceptional value and long-term reliability.