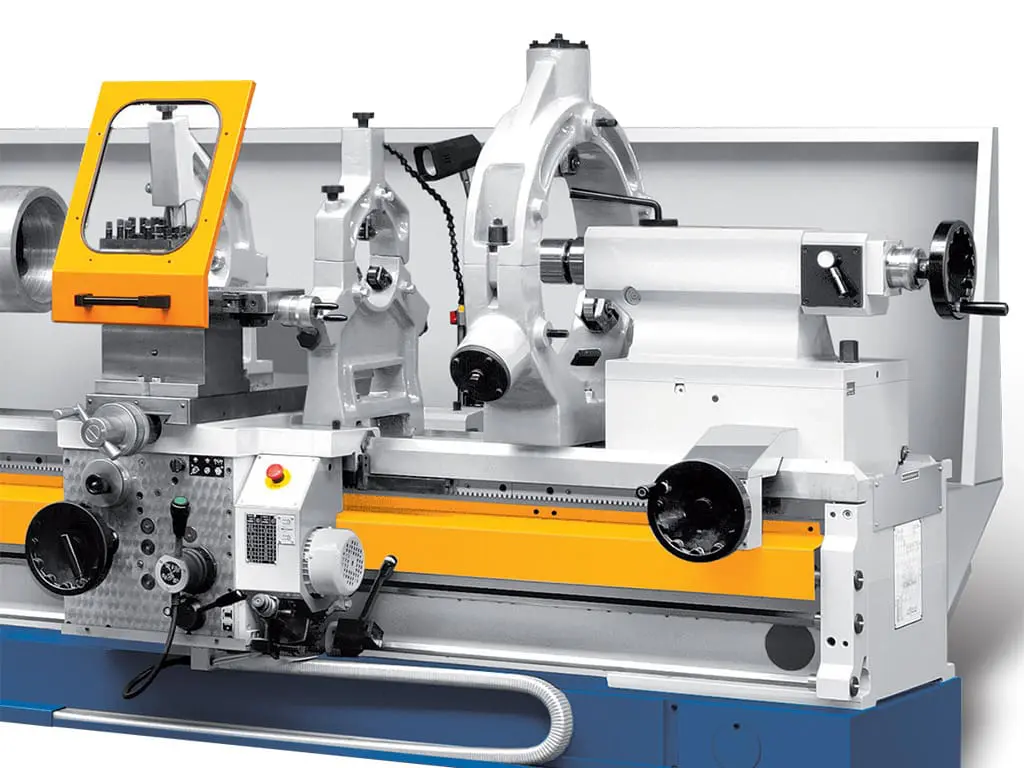

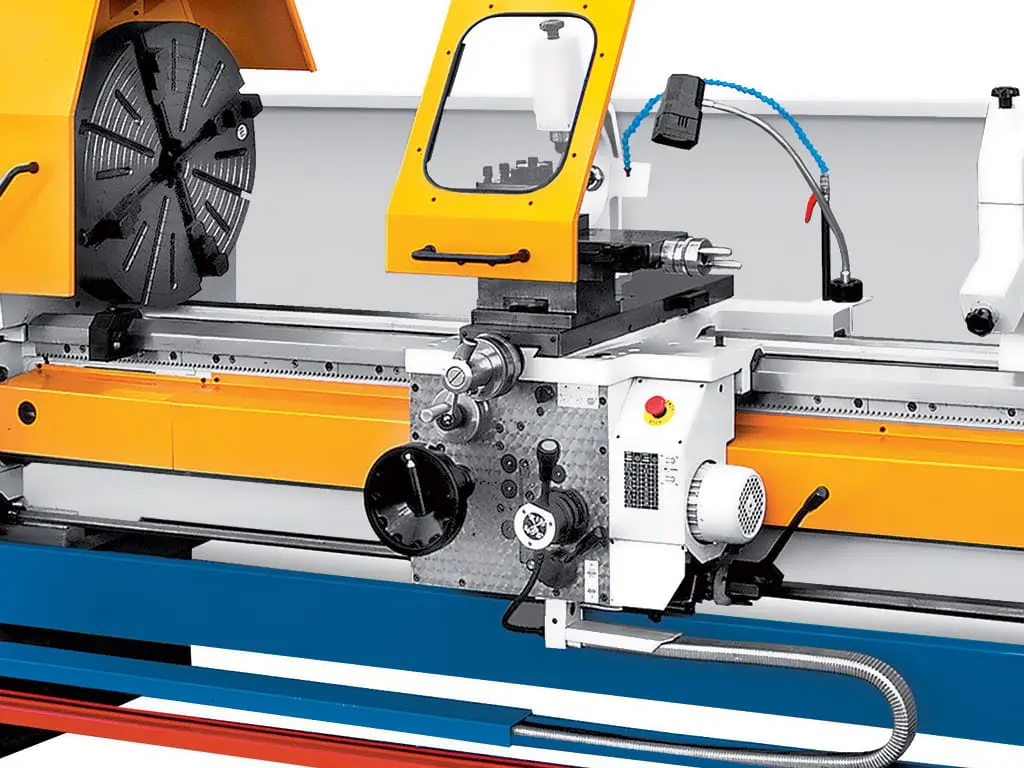

Meyer Euroline EC Precision Centre Lathes

The Meyer Euro Line range of metal lathes continues with the high capacity EV, EX, and EC models, featuring wider bed designs and high-powered motors. The EX range includes the EX 1410 model, with a 1410mm swing over bed and, by special request, up to 9000mm distance between centres.

The EC models offer a very large bore through the headstock and can be supplied with additional free-standing steadies for working with longer material lengths. All models are available in a variable speed version, as well as with a wide range of optional features and accessories. As with the smaller models, these machines offer thread cutting in a large range of types and pitches.

| EC 800 – 260/1500

EC 800 – 260/2000 EC 800 – 260/3000 EC 800 – 260/4000 EC 800 – 260/5000 EC 800 – 260/6000 |

EC 800 – 315/1500

EC 800 – 315/2000 EC 800 – 315/3000 EC 800 – 315/4000 EC 800 – 315/5000 EC 800 – 315/6000 |

||

| Capacities | |||

| Height of centres | mm | 400 | |

| Swing over Bed | mm | 800 | |

| Swing over cross slide | mm | 560 | |

| Swing in gap* | mm | 990 | |

| Width of bed | mm | 560 | |

| Distance between Centres | mm | 1500 – 2000 – 3000 – 4000 – 5000 – 6000 | |

| Spindle | |||

| Spindle nose DIN 55027 | No | A20 – A2.20 | |

| Spindle bore | mm | 260 | 315 |

| Spindle taper | Metric | 318 | |

| Headstock | |||

| Number of spindle speeds | – | 12 | |

| Spindle speed ranges | rpm | 8 – 400 | |

| Main motor power | kW | 11 (15) | |

| Feeds | |||

| Number of feeds | – | 152 | |

| Longitudinal feed range | mm/rev | 0.039 – 15 | |

| Cross feed range | mm/rev | 0.02 – 7.5 | |

| Threads | |||

| Number of threads | – | 76 of each kind | |

| Metric thread range | mm | 0.5 – 150 | |

| Inch thread range | Tpi | 60 – 1/5 | |

| Module thread range | Module | 0.125 – 37.5 | |

| DP thread range | DP | 240 – 4/5 | |

| Carriage | |||

| Cross slide travel | mm | 410 | |

| Top slide travel | mm | 150 | |

| Tailstock | |||

| Quill diameter | mm | 105 | |

| Quill taper | Morse | No.6 | |

| Quill travel | mm | 225 | |

| Dimensions | |||

| Length | mm | 4400 – 8900 | |

| Width | mm | 1600 | |

| Height | mm | 1900 | |

| Weight | kg | 6000 – 8950 | 6220 -9050 |

* With option machine bed gap

Features

- High quality European built machines

- Rigid build ensures high chip removal rate during the rough turning operation

- Highly resistant steel with high loading capacity used for all gear and spindle parts

- Cast bed with hardened and ground bed ways

- Gap bed design

- Variable spindle speed

- Rapid traverse

- Four position square toolpost

- Chuck guard with interlock switch

- Lead screw guard

- Low voltage halogen work light

- Centralised lubrication

- Chip collection tray

- Coolant system

- Full length rear splash guard

Options

- Variable spindle speed

- 2 or 3 axis digital read out

- Thread dial indicator

- Quick change tool post

- 3 and 4 jaw chucks

- Face plate

- Fixed steady

- Follow rest

Meyer Euroline EC Precision Centre Lathes

The Meyer Euroline EC Precision Centre Lathes are a benchmark in high-capacity metalworking, combining durability, versatility, and precision. Designed to meet the demands of industries requiring heavy-duty machining, the EC models cater to users who need powerful lathes with exceptional functionality. Alongside the wider bed designs and high-powered motors that define the Euroline range, the EC models stand out for their unique capabilities and additional options.

Versatility in the Euroline Range

The Euroline range extends across the EV, EX, and EC models, with each variant tailored to meet specific machining needs. The EX range, for instance, includes the robust EX 1410 model, which boasts an impressive 1410mm swing over the bed. For specialised requirements, customers can request models with up to 9000mm distance between centres, making these lathes ideal for working with exceptionally long materials.

The EC models distinguish themselves through their large bore through the headstock, accommodating larger workpieces with ease. They are particularly suited for projects involving long material lengths, and to facilitate this, they can be equipped with free-standing steadies. This feature enhances stability during machining, ensuring precision over extended distances.

Performance and Precision

Performance is a key feature of the Meyer Euroline EC Precision Centre Lathes. All models in the range come with variable speed versions, allowing operators to adapt the machine’s speed to suit specific materials and tasks. This flexibility improves the efficiency and quality of operations, particularly for intricate machining.

Thread cutting is another area where these lathes excel. The EC models offer the capability to cut threads in a wide variety of types and pitches, accommodating diverse industry standards. Whether you are working with metric, imperial, or custom thread specifications, these lathes deliver consistent accuracy.

Optional Features and Accessories

The EC models are customisable with a range of optional features and accessories, enabling users to tailor the machine to their exact requirements. Popular additions include advanced tool holders, specialised chucks, and digital readout systems that enhance precision and ease of use. By choosing from these options, operators can optimise their machines for specific tasks, increasing productivity and output quality.

For those requiring heavy-duty operations, optional hydraulic steady rests provide additional support, particularly when machining larger or longer workpieces. This ensures that even the most challenging jobs can be completed with confidence.

Build Quality and Reliability

Meyer Euroline EC Precision Centre Lathes are renowned for their robust construction and reliability. The wider bed designs enhance stability during heavy-duty operations, reducing vibrations and ensuring smooth, consistent machining. This focus on structural integrity makes the EC models a long-lasting investment for workshops and factories that demand consistent performance.

The high-powered motors fitted in these lathes further contribute to their efficiency, delivering the torque required for machining tough materials like steel, cast iron, and alloys. This combination of power and precision ensures that the EC models are well-suited for both standard and specialised applications.

Applications Across Industries

The versatility and capability of the Meyer Euroline EC models make them an excellent choice across a variety of industries, including manufacturing, engineering, and metal fabrication. These lathes are particularly valued in applications requiring:

- Custom machining for large or long components.

- Thread cutting across diverse types and pitches.

- Heavy-duty material removal for tough materials.

- Precision machining for high-specification projects.

Whether you are producing bespoke components or managing high-volume production, the EC models provide the adaptability and performance needed to achieve exceptional results.

A Complete Machining Solution

The Meyer Euroline EC Precision Centre Lathes combine the best features of modern machining technology, including variable speed control, large bore headstocks, and optional steadies, to offer a complete solution for professionals. Their customisation options and durable construction make them an invaluable asset for workshops aiming to enhance their capabilities.

For businesses seeking a lathe that delivers exceptional precision, power, and reliability, the Meyer Euroline EC models are an outstanding choice. By investing in these machines, operators gain a versatile and long-lasting tool that meets the demands of modern machining.