CMS Proline Waterjet Cutting System

The ultimate machine tool specifically conceived and designed with advanced technical solutions for the waterjet cutting technology, in order to achieve unmatched performance.

The CMS Proline is built around a stainless-steel frame ready for integration with the “Dredge”, a fully automated and maintenance free abrasive removal system, an automatic water level control for submerged cutting and rotary option for pipes processing.

The overall machine structure, especially the rugged gantry system, offers unmatched rigidity and thus consistent cutting accuracy over time, thanks also to the ground helical rack and pinions, combined with high precision gearboxes.

| Model | CMS Smartline | CMS Proline | ||

| Size | 2040 | 1730 | 2040 | |

| X Axis | mm | 4,000 | 4,250 | |

| Y Axis | mm | 2,000 | 2,000 | |

| Z Axis | mm | 250 (3-Axis) / 150 (5-Axis) | 300 (3-Axis) / 200 (5-Axis) | |

| B Axis (5 Axis Only) | ° |

±60 |

±62 | |

| C Axis (5 Axis Only) | N/A | Infinite | ||

| XY Axis Rapid Speed | mm/min | N/A | 40,000 | |

| Rest Surface | mm | 4150 x 2080 | 3700 x 2025 | 4650 x 2050 |

| Workable Load Capacity | kg/m2 | 500 | 1,000 | 1,000 |

| Position Accuracy | mm | +/- 0.1 | +/- 0.035 | |

| Position Repeatability (BS) | mm | +/- 0.05 | +/- 0.025 | |

| Installed Power | HP | 60 | 60 | |

| Overall Dimensions | mm | 5,595 x 7,400 x 4,000 | 7,152 x 3,183 x 4,1049 | 8,158 x 3,483 x 3,900 |

| Weight (Empty) | kg | 3,900 | 4,000 | 8,000 |

Features

- 21.5″ Touch Screen Controller

- New Z axis strokes up to 300mm 3 axis, up to 200mm 5 axis

- Easyjet DDX CAD/CAM Software

- Electronic hopper for abrasive automatic monitoring with sensors for cutting parameters automatic control

- Probe system for consistent cutting heights

- Integrated electric cabinet in the tank frame for a reduced footprint

- Racks and Helicoidal Pinions

- Powder free labyrinth panels for the Axes to protect the linear guides and racks from water, dust and abrasives

- Automatic Safety Doors

- Automatic hose reel

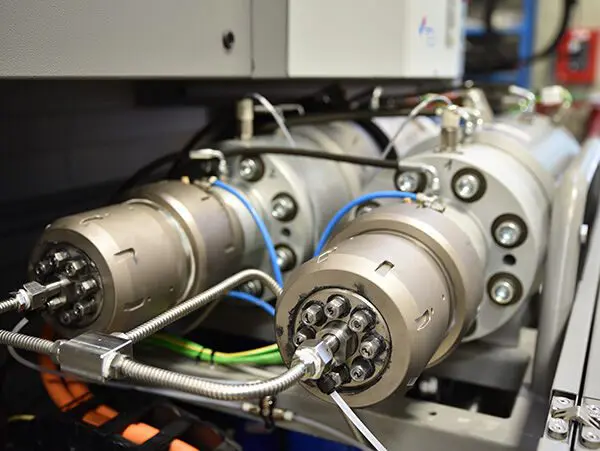

- Intensifier chamber

- Automatic lubrication of all axes

- Dredging system for “no maintenance” abrasive removal

- 330kg pressurised abrasive feeding system

Options

- 60Hp Jetpower Evo Pressure Intensifier

- 4139 / 6200 Technocut Greenjet Evo Pressure Intensifier

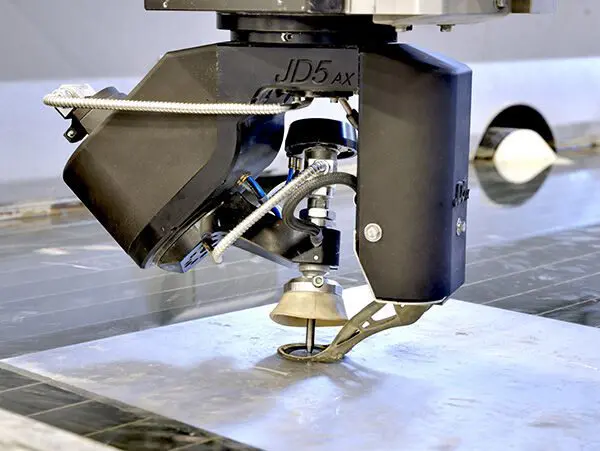

- JD5AX Cutting Head

- 5AX Head Position

- Cutting head camera

- Drilling Head

- Laser pointer

- Anti-reflective or steel honeycomb work table grids

- Rotating axis for pipe processing

The CMS Proline Waterjet Cutting System stands out as the ultimate machine tool designed with cutting-edge technical solutions to deliver unmatched performance. This advanced system harnesses the power of waterjet cutting technology, enabling precise, efficient, and versatile operations across various materials.

From its robust stainless-steel frame to its high-precision components, the CMS Proline is a testament to quality engineering. Whether for general cutting tasks or specialized applications, this system excels in performance, reliability, and ease of use.

Stainless-Steel Frame with Advanced Features

At the heart of the CMS Proline is a stainless-steel frame engineered for durability and precision. This robust foundation ensures the machine’s longevity and stability during high-intensity operations. The frame is ready for seamless integration with several advanced features:

- Dredge System: A fully automated, maintenance-free abrasive removal system, the Dredge enhances operational efficiency by continuously clearing spent abrasive material. This minimizes downtime and reduces manual intervention.

- Automatic Water Level Control: Ideal for submerged cutting, this feature allows operators to adjust the water level with ease, ensuring cleaner cuts and quieter operation.

- Rotary Option for Pipes: The CMS Proline also offers a rotary option, enabling precise processing of pipes and cylindrical materials, further expanding its versatility.

Rugged Gantry System for Unmatched Rigidity

The CMS Proline’s gantry system is designed with a focus on strength and stability. The rugged construction provides unparalleled rigidity, which is essential for maintaining consistent cutting accuracy over extended periods of use. This robust design not only minimizes vibration but also ensures precise results, even for intricate cutting tasks.

Precision Components for Consistent Performance

The cutting accuracy of the CMS Proline is further enhanced by its high-precision components. These include:

- Ground Helical Rack and Pinions: These components deliver smooth, precise motion, ensuring that every cut meets exact specifications. The helical design minimizes backlash and increases the machine’s operational efficiency.

- High-Precision Gearboxes: Combined with the rack and pinion system, these gearboxes ensure seamless motion and precise control. The result is superior accuracy and repeatability across a wide range of cutting applications.

Versatility and Application Range

One of the standout features of the CMS Proline is its versatility. It can cut a wide variety of materials with remarkable precision, including:

- Metals: Stainless steel, aluminium, and titanium.

- Composites: Carbon fibre and other advanced materials.

- Stone and Glass: Perfect for decorative and architectural applications.

- Plastics: Ensuring clean edges without thermal distortion.

This versatility makes the CMS Proline an excellent choice for industries such as aerospace, automotive, architecture, and manufacturing.

User-Friendly Operation and Maintenance

The CMS Proline is designed with the operator in mind, offering user-friendly controls and minimal maintenance requirements. The integration of advanced automation features ensures that the system is easy to operate, while the maintenance-free components reduce overall upkeep. These features combine to provide a hassle-free user experience, allowing operators to focus on productivity and quality.

Sustainability and Efficiency

The CMS Proline is not only a high-performance machine but also an environmentally conscious one. Submerged cutting reduces noise pollution and minimizes dust, creating a safer and more sustainable working environment. The efficient abrasive removal system further contributes to sustainability by reducing waste and extending the life of consumables.

Why Choose the CMS Proline?

The CMS Proline Waterjet Cutting System is the ideal solution for businesses seeking precision, reliability, and versatility in a cutting machine. Its advanced features, robust design, and user-friendly operation set it apart from the competition. Whether for intricate designs or heavy-duty applications, the CMS Proline delivers exceptional results every time.

Investing in the CMS Proline means choosing a cutting-edge machine that will enhance productivity, reduce operational costs, and deliver unparalleled performance for years to come.