Metal bending is the process of shaping sheet or plate by applying force to create permanent, precise bends for manufacturing and fabrication.

Bending is one of the most important processes in metal fabrication, transforming flat sheet metal into three-dimensional components used across countless industries — from HVAC ductwork and architectural cladding to structural steelwork and precision engineering.

Getting the fundamentals right not only improves accuracy and repeatability but also reduces material waste, production time, and costs.

In this guide, we’ll cover:

- What metal bending is and how it works

- Key principles like bend radius, springback, and bend allowance

- Different bending methods and the machinery involved

- Best practices for designing bent components

- FAQs about metal bending

Whether you’re new to bending or looking to refine your processes, this article will help you understand the theory and choose the right machinery for your workshop.

1. What is Metal Bending?

Metal bending is the process of applying force to a sheet, plate, or section to cause plastic deformation — a permanent change in shape.

When metal is bent:

- The outer fibres of the bend stretch under tension

- The inner fibres compress under compression

- Between them lies the neutral axis, a theoretical layer that remains unchanged in length

Once the forming force is removed, the metal partially springs back towards its original position. This is known as springback, and it must be accounted for when designing and programming bends.

2. Key Principles and Calculations

Understanding a few key terms helps you achieve precise, repeatable bends. These calculations are based on metric units (mm).

2.1 Inside Bend Radius

The inside bend radius (R) is the distance from the centre of the bend to the inside surface.

-

A typical rule of thumb is that the inside bend radius should be at least equal to the material thickness (t).

-

Bending below this minimum radius risks cracking, uneven stretching, or weakened parts.

For example, if bending 3 mm mild steel, a minimum inside bend radius of 3 mm is recommended.

2.2 K-Factor and Bend Allowance

The K-Factor defines the location of the neutral axis within the thickness of the material. It is typically between 0.3 and 0.5, depending on material type and forming method.

Using this, you can calculate Bend Allowance (BA) — the length of material consumed by the bend.

\( \mathrm{BA} = \theta \times (R + K \times t) \times \frac{\pi}{180} \)

Where:

-

θ = bend angle (degrees)

-

R = inside bend radius (mm)

-

t = material thickness (mm)

-

K = K-Factor

Calculating BA helps you determine the correct flat blank size before bending.

2.3 Springback

Springback occurs when the material elastically recovers slightly after bending.

-

Mild steel typically has minimal springback.

-

Stainless steel and high-strength alloys have more pronounced springback.

To counter this, operators may:

-

Overbend slightly beyond the desired angle

-

Use bottoming or coining techniques, which reduce springback by forcing the material into the die with higher pressure

2.4 Tonnage Requirements

The force required to bend a part depends on:

-

Material thickness

-

Bend length (width of the part in the press brake)

-

Inside bend radius

-

Material tensile strength

Example:

Bending 3 mm mild steel over a 1,000 mm length may require around 30 tonnes of force depending on the tooling and method used.

For heavy-duty bending of thick plates or long parts, consider a more robust machine like an H-Frame Press or Press Brake.

3. Methods of Bending and Suitable Machinery

Different bending methods suit different applications. Here’s how each works, and which machines you’ll need.

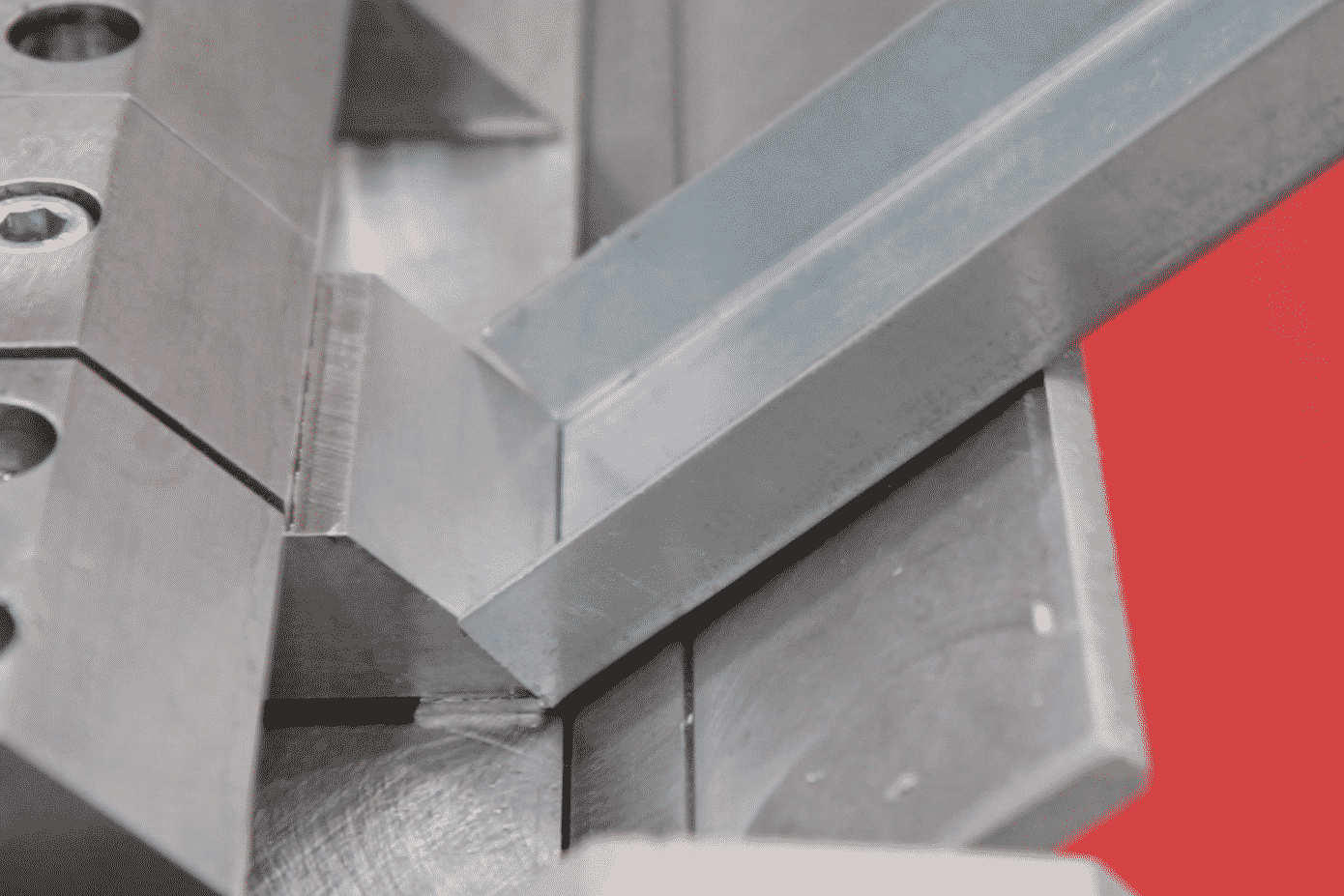

3.1 Press Brakes

Press Brakes are the workhorse of modern metal bending, used for everything from simple angles to complex multi-bend parts.

Common bending techniques:

-

Air Bending – Versatile and efficient, allows multiple angles with the same tooling.

-

Bottoming – Punch drives material fully into the die, providing greater precision and less springback.

-

Coining – High-pressure method that nearly eliminates springback, ideal for critical applications.

Press brakes are ideal for precision sheet metal work across industries like construction, aerospace, and manufacturing.

3.2 Box & Pan Folders

Box & Pan Folders, also known as finger folders, are perfect for creating boxes, trays, and enclosures.

The removable fingers allow flanges to be bent without interfering with adjacent bends, making them essential for ductwork, cabinetry, and custom enclosures.

3.3 H-Frame Presses

When working with thicker materials or heavy-duty applications, an H-Frame Press offers high structural rigidity and stability.

These machines are suited for one-off bends, forming structural components, or tasks that require extreme force but don’t need CNC precision.

3.4 Horizontal Bending Machines

Horizontal Bending Machines are ideal for long, straight flanges or edge bending.

The tool moves horizontally, which makes them perfect for repetitive bending of parts like brackets or supports.

We can offer a huge range of tooling for these machines, such as bar straightening, extended die, tubular tooling or even custom tools – making them incredibly versatile – see this separate blog for more information.

3.5 Rolling for Curved Parts

For large-radius bends, cylinders, or hoops, rolling is the best method.

-

Section Rolls – For round tube, angle, or bar rolling on the edges.

-

Bending Rolls – For sheet metal, ideal for curved panels or cylindrical shapes.

4. Design Best Practices

To prevent costly mistakes and ensure high-quality results, consider these guidelines when designing bent components:

-

Hole placement: Keep holes at least 4 × material thickness away from the bend line to avoid distortion.

-

Minimum flange length: Ensure flanges are long enough for tooling to grip securely.

-

Bend relief: Use notches or reliefs near bends to prevent tearing or warping.

-

Material consistency: Always check for flatness, coatings, and batch differences.

-

Prototyping: Run test bends before full production to confirm calculations and tolerances.

5. Choosing the Right Machinery

| Application | Recommended Machine | Why |

|---|---|---|

| Precision sheet bending | Press Brake | High accuracy and flexibility |

| Boxes, trays, ducting | Box & Pan Folder | Finger tooling for complex shapes |

| Heavy-duty plate bending | H-Frame Press | Maximum strength for thick material |

| Straight flanges or repetitive bends | Horizontal Bending Machine | Fast, efficient edge bending |

| Large radius rings in tube or bars | Section Rolls | Perfect for curved profiles and rolled sections |

| Large curves in sheet materials | Bending Rolls | Perfect for curved panels and cylindrical shapes |

6. Frequently Asked Questions (FAQs)

Here are some of the common questions we receive around bending.

As a general rule, the minimum inside bend radius should be equal to the sheet thickness.

For 3 mm mild steel, aim for a 3 mm inside radius to prevent cracking.

Published 25th September 2025

Use the Bend Allowance (BA) formula:

Flat Length=Flange 1+Flange 2−Bend Deduction

This ensures the final bent part matches your design dimensions.

Published 25th September 2025

Springback is the metal’s natural tendency to partially return to its original shape after bending.

To manage springback:

- Overbend slightly past the required angle

- Use bottoming or coining techniques

- Select tooling and materials that minimise springback

You need to consider how the metal can distort.

Published 25th September 2025

For rolling sheet metal into curved panels or cylinders, use a set of Sheet Rolls

Published 25th September 2025

Force depends on material thickness, bend length, and tensile strength.

For example, bending 3 mm mild steel over a 1,000 mm length typically requires around 30 tonnes.

Published 25th September 2025

Conclusion

Understanding the fundamentals of metal bending — from bend radius and springback to choosing the right machine — is essential for precision and efficiency in fabrication.

At Selmach Machinery, we offer a complete range of bending equipment, from Press Brakes and Box & Pan Folders to Section Rolls and H-Frame Presses.

Our experts can help you select the right machine for your workshop and application.

Contact us today to discuss your bending needs.

Published 25th September 2025