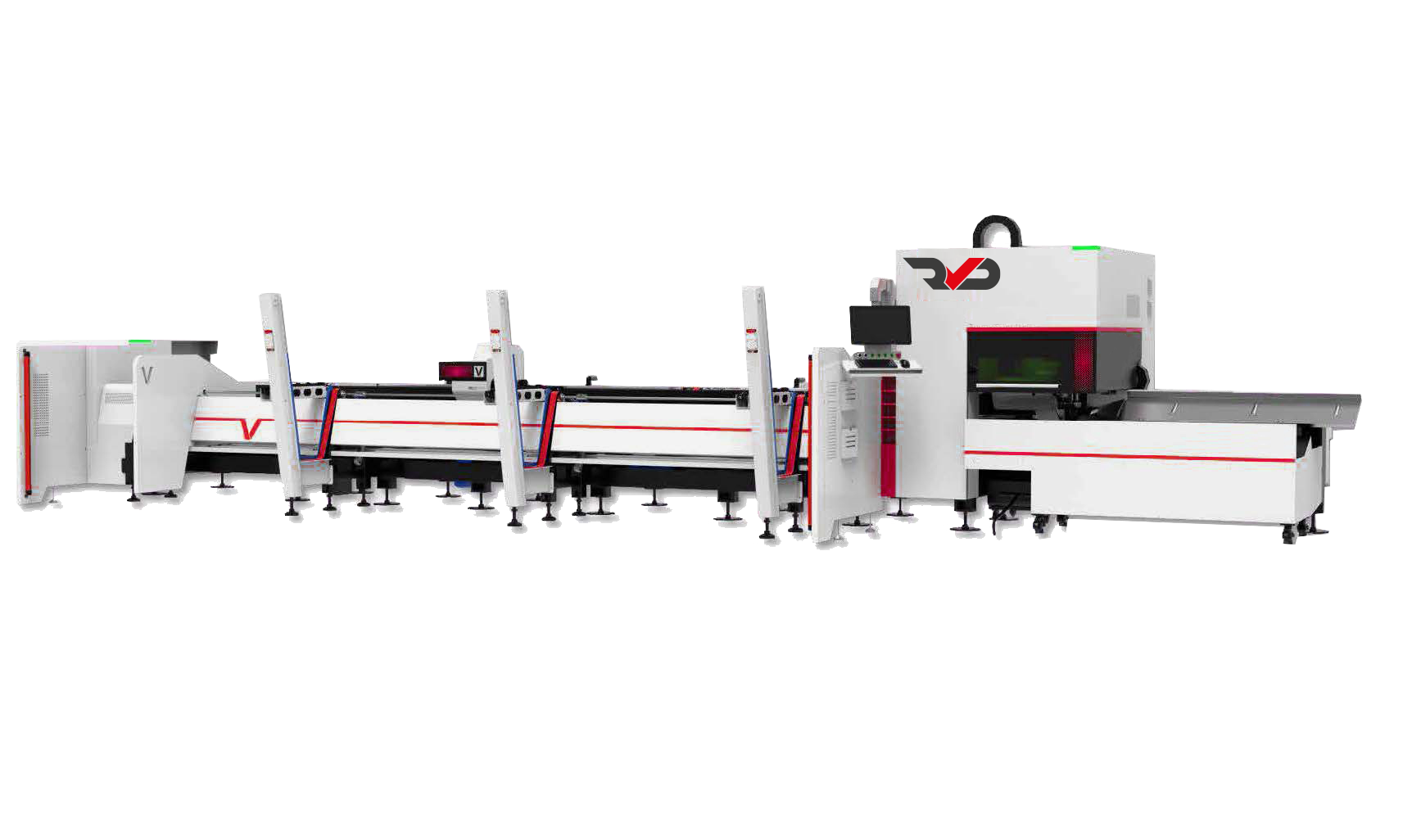

Tube and Profile Laser Cutting Machines UK

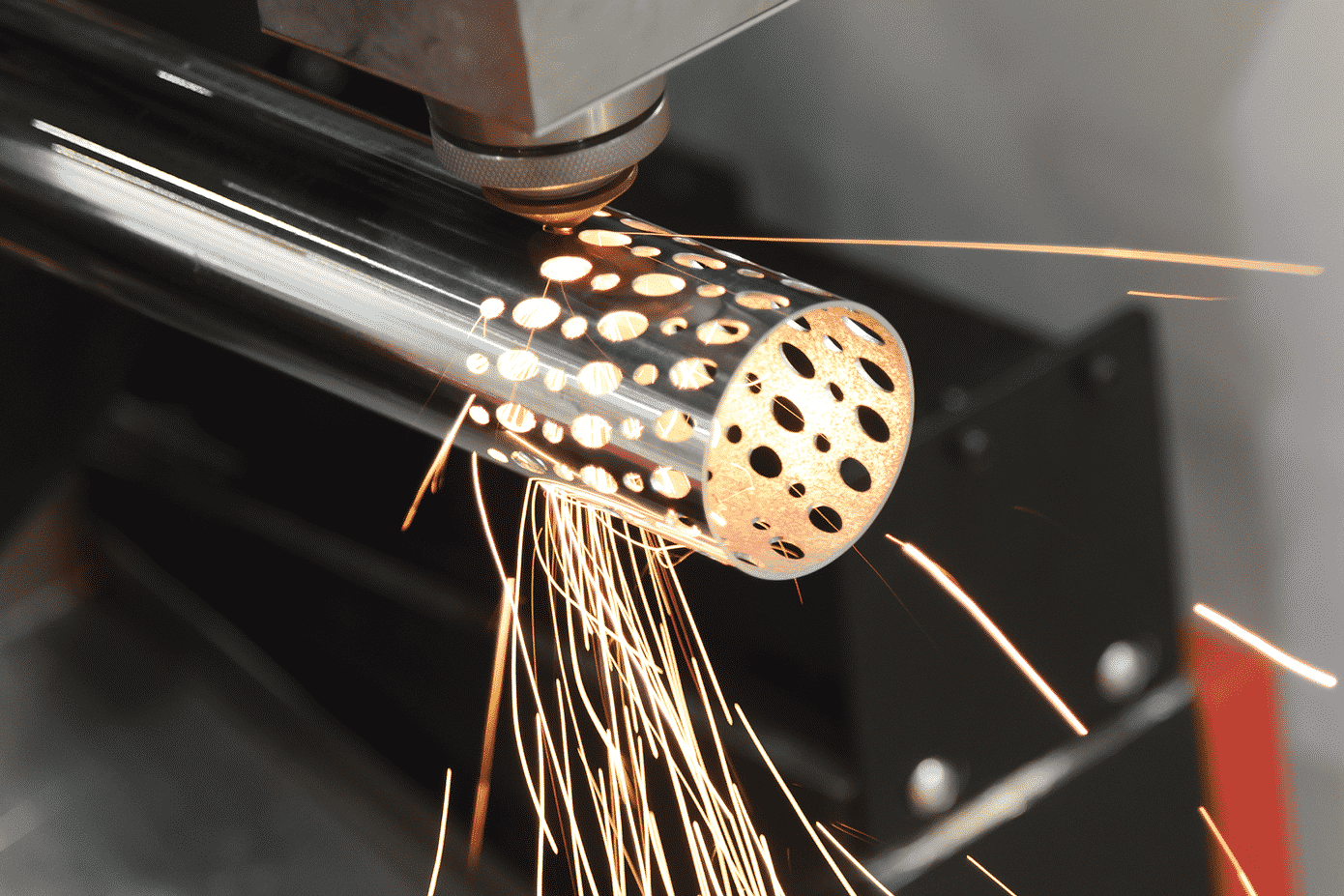

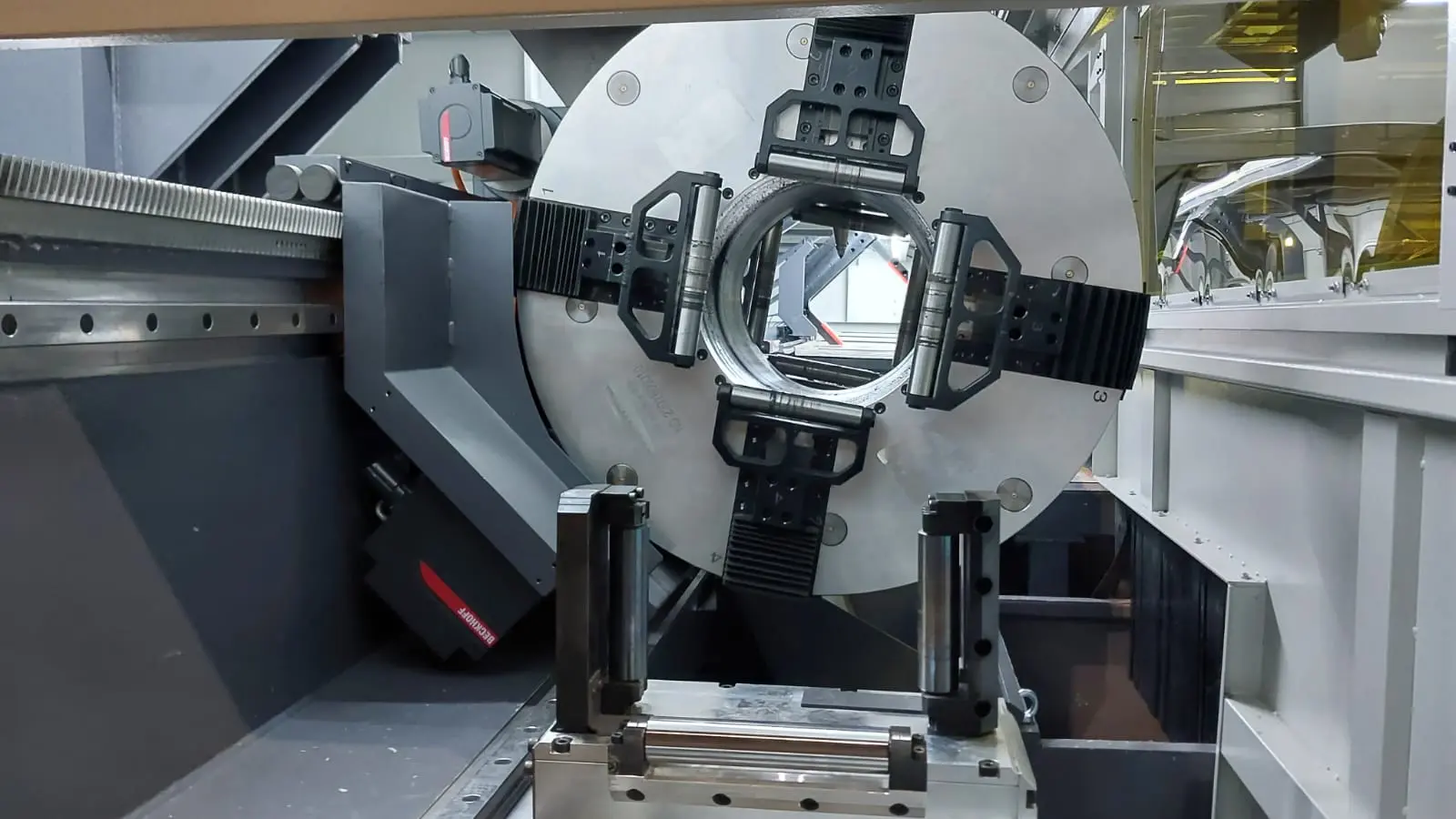

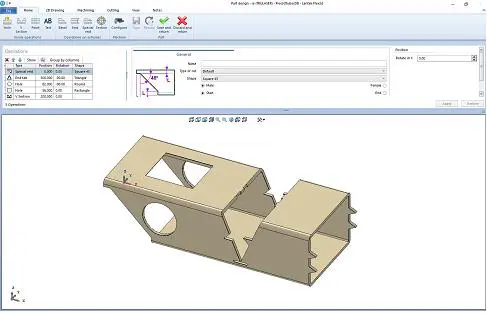

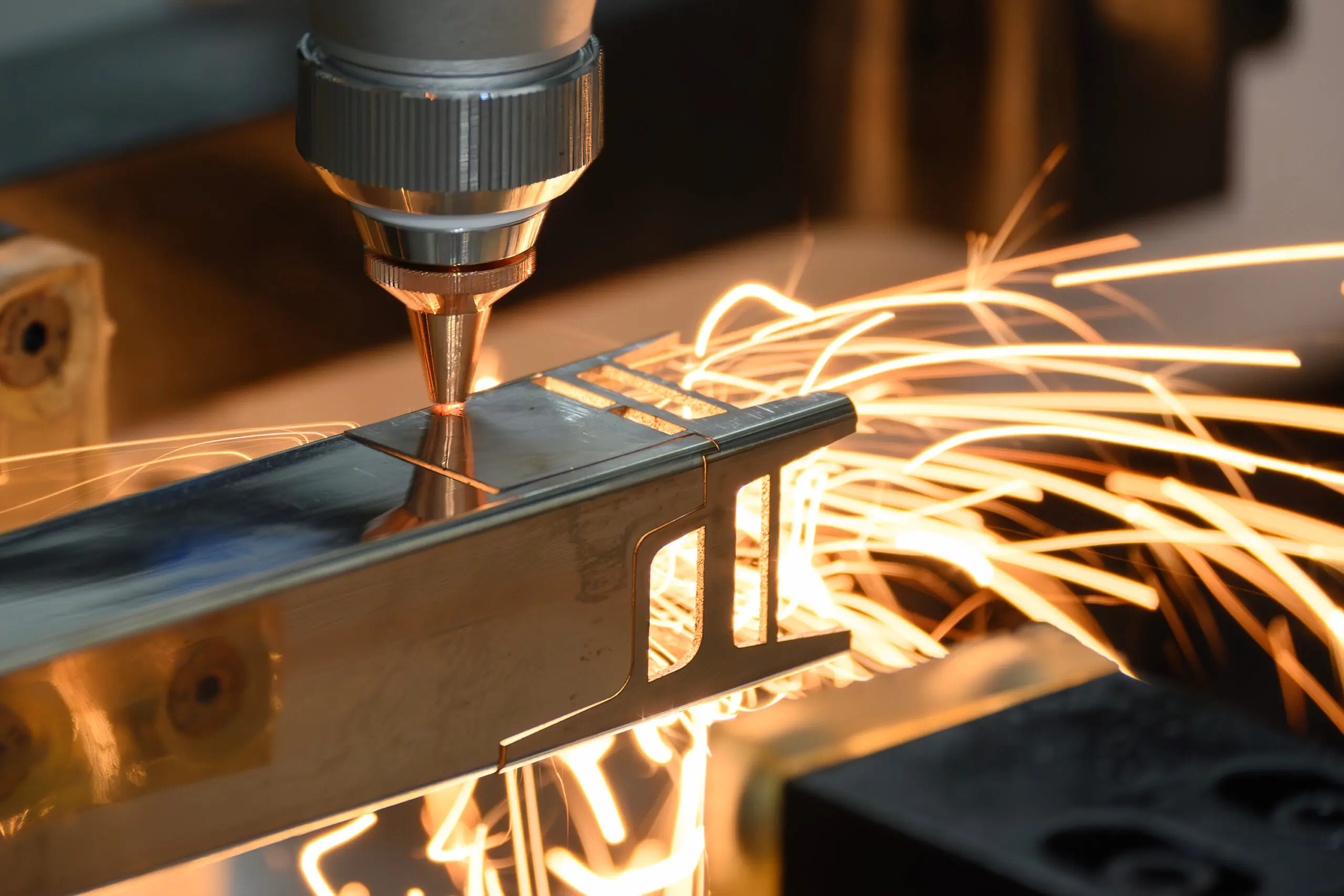

Tube and profile laser cutting has become a core capability for modern fabrication, giving workshops cleaner cuts, tighter tolerances and far greater production speed. Selmach supplies a versatile range of CNC fibre tube and profile laser cutting machines for manufacturers across the UK, built to handle round, square and rectangular tube as well as beam, channel, angle and other open profiles.

Each installation is supported by our experienced engineering team, ensuring you choose a system that fits your materials, workflow and long-term production goals.

![Morgan Rushworth BLT Tube Laser [Web]](https://selmach.com/wp-content/smush-webp/2022/12/Morgan-Rushworth-BLT-Tube-Laser-Web.png.webp)