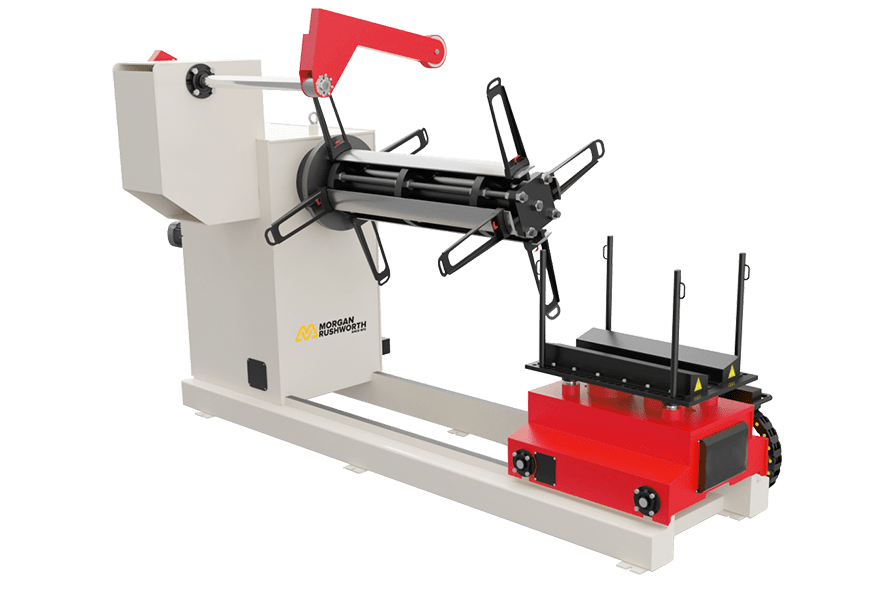

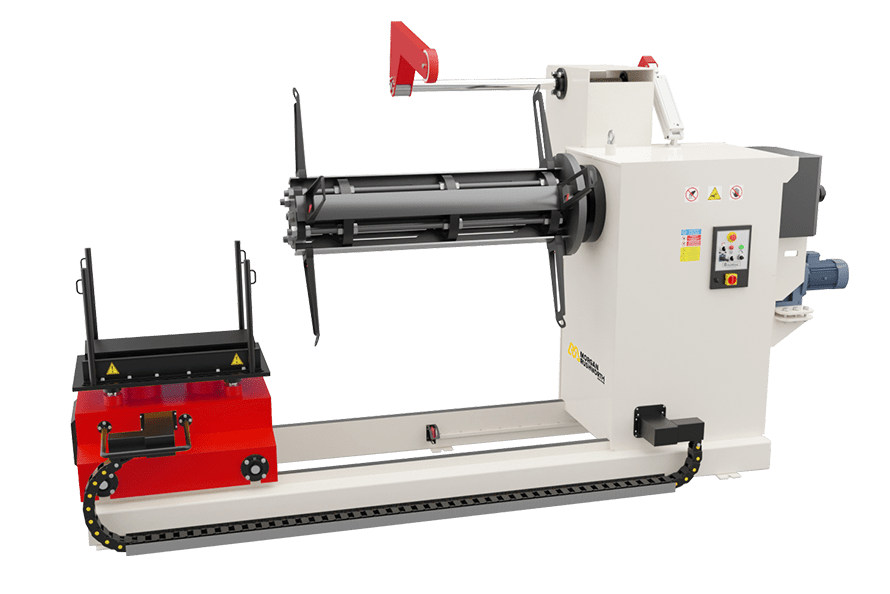

Morgan Rushworth MDH Hydraulic Decoiling Machinery

The Morgan Rushworth MDH Hydraulic Decoiling Machinery is a robust solution designed for heavy-duty coil handling. With capacities ranging from 4,000kg to 15,000kg, it accommodates materials up to 1,300mm wide and 0.5–2mm thick, making it ideal for various industrial applications.

Equipped with motorised loop control and proximity sensor-controlled speed, the machine ensures precise and seamless integration with production lines. Coils are decoiled from the top, with speed adjustable to match operational requirements. For enhanced efficiency, the optional Hydraulic Loading Car simplifies the loading and unloading process, saving time and reducing manual effort.

| MODEL | MDH600.4000 M / F | MDH600.6000 M / F | MDH800.10000 M / F | MDH1300.15000 M / F | |

| Decoiler Type | Single Head / Hydraulic | Single Head / Hydraulic | Single Head / Hydraulic | Single Head / Hydraulic | |

| Decoiler Capacity | kg | 4,000 | 6,000 | 10,000 | 15,000 |

| Coil Inner Diameter (min) | Ø mm | 490 | 490 | 490 | 490 |

| Coil Inner Diameter (max) | Ø mm | 560 | 560 | 560 | 560 |

| Working Capacity Outside Diameter | Ø mm | 1,500 | 1,500 | 1,600 | 1,600 |

| Working Thickness | mm | 0.5 – 2 | 0.5 – 2 | 0.5 – 2 | 0.5 – 2 |

| Width Capacity (Max) | mm | 600 | 600 | 800 | 1,300 |

| Roll Inside Pressure System | Hydraulic Mandrel | Hydraulic Mandrel | Hydraulic Mandrel | Hydraulic Mandrel | |

| Mandrel Operating System | Conical Expansion | Conical Expansion | Conical Expansion | Conical Expansion | |

| Power Transfer System for Drum | Motorised with Reducer | Motorised with Reducer | Motorised with Reducer | Motorised with Reducer | |

| Speed Control System | Adjustable drum rotary speed | Adjustable drum rotary speed | Adjustable drum rotary speed | Adjustable drum rotary speed | |

| Unrolling Security | Upper pressure arm | Upper pressure arm | Upper pressure arm | Upper pressure arm | |

| Rotation Speed | RPM | Maximum 14 (adjustable) | Maximum 14 (adjustable) | Maximum 14 (adjustable) | Maximum 14 (adjustable) |

| Control System | Laser Sensor | Laser Sensor | Laser Sensor | Laser Sensor | |

| Working Direction | Upper / bottom | Upper / bottom | Upper / bottom | Upper / bottom | |

| Hydraulic Power | From the main power unit | From the main power unit | From the main power unit | From the main power unit | |

| Hydraulic Loading Car (Optional) | |||||

| Compatible Decoiler | MDH600.4000 M / F | MDH600.6000 M / F | MDH800.10000 M / F | MDH1300.15000 M / F | |

| Capacity | kg | 4,000 | 6,000 | 10,000 | 10,000 |

| Max. Coil Width | mm | 600 | 600 | 800 | 1,000 |

| Max. Coil OD | Ø mm | 1,500 | 1,500 | 1,600 | 1,600 |

| Type | V type (Single) | V type (Single) | V type (Single) | V type (Single) | |

| Traversing Style | Hydraulic | Hydraulic | Hydraulic | Hydraulic | |

| Lifting Stroke | mm | 300 (Hydraulic Piston) | 300 (Hydraulic Piston) | 300 (Hydraulic Piston) | 300 (Hydraulic Piston) |

| Control System | Via Control Panel | Via Control Panel | Via Control Panel | Via Control Panel | |

Features

- Coil holding from inside via mandrel expansion

- Coil outfeeds from the top

- Decoil at pre-determined speeds

- Electronically operated turning and stopping system via sensor.

- Mandrel working includes the cross (scissor) construction system.

Options

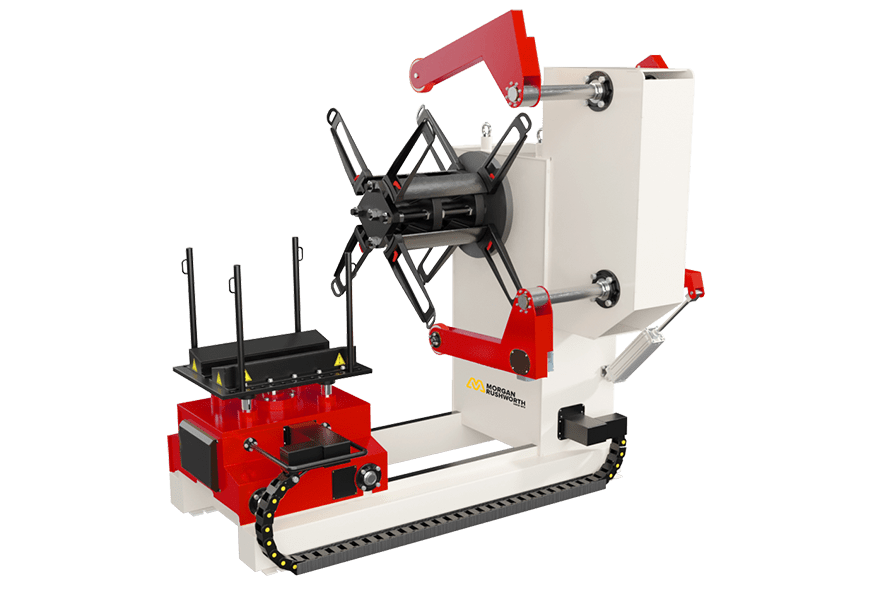

- Hydraulic Loading Car

Introduction to the MDH Hydraulic Decoiler

The Morgan Rushworth MDH Hydraulic Decoiling Machinery is a state-of-the-art solution for heavy-duty coil handling. Engineered for versatility and precision, this machinery caters to a wide range of industrial applications. With a capacity range from 4,000kg to 15,000kg, the MDH decoiler is built to handle materials up to 1,300mm wide and thicknesses between 0.5mm and 2mm. It combines robust construction with innovative features to enhance productivity and streamline operations.

Key Features and Specifications

The MDH Hydraulic Decoiler is packed with advanced features that set it apart:

- Capacity Range: Supports coil weights between 4,000kg and 15,000kg, ensuring suitability for light, medium, and heavy-duty applications.

- Material Dimensions: Handles materials up to 1,300mm in width and thicknesses ranging from 0.5mm to 2mm, accommodating a variety of industrial requirements.

- Motorised Loop Control: Guarantees smooth and consistent material handling, reducing the risk of errors and downtime.

- Proximity Sensor-Controlled Speed: Ensures precise speed adjustments for seamless integration with production lines.

- Top Decoiling Design: The top decoiling mechanism simplifies the process and ensures reliable feeding into the production system.

These features make the MDH decoiler a versatile and reliable addition to any production environment.

Efficiency Through Innovation

The MDH Hydraulic Decoiler is designed with efficiency at its core. The motorised loop control ensures that materials are fed smoothly and consistently, eliminating the need for manual intervention and reducing the risk of operational errors. The proximity sensor-controlled speed further enhances this efficiency, allowing the decoiler to adapt to the pace of the production line for optimal performance.

Enhanced Productivity with Top Decoiling

Top decoiling is a standout feature of the MDH Hydraulic Decoiler. By feeding materials from the top, the system simplifies the coil handling process and ensures accurate alignment with downstream machinery. This feature minimises material waste and ensures high-quality results in various industrial applications, from automotive manufacturing to metal fabrication.

Optional Hydraulic Loading Car

For businesses seeking to maximise productivity, the optional Hydraulic Loading Car is a valuable addition. This feature significantly reduces the time and effort required to load and unload coils. The loading car enhances workplace safety by minimising manual handling and streamlining the process, allowing operators to focus on other critical tasks. This optional component is ideal for facilities handling high volumes of materials and looking to optimise their workflows.

Applications Across Industries

The MDH Hydraulic Decoiler is a versatile solution suitable for a wide range of industries:

- Automotive Manufacturing: Supports precise and efficient material feeding for the production of automotive components.

- Metal Fabrication: Handles a variety of metals for processes such as stamping, punching, and cutting.

- Construction Materials: Ideal for processing steel and other materials used in construction applications.

- Electronics Production: Ensures accurate handling of delicate materials used in electronic components.

The adaptability of the MDH decoiler makes it an indispensable tool for diverse industrial settings.

Benefits of the MDH Hydraulic Decoiler

Investing in the Morgan Rushworth MDH Hydraulic Decoiling Machinery offers several key advantages:

- Improved Efficiency: The motorised loop control and sensor-driven speed adjustments ensure consistent material flow and reduce downtime.

- Enhanced Accuracy: The top decoiling design guarantees precise alignment and feeding, minimising material waste.

- Versatility: Capable of handling a wide range of coil sizes and materials, the MDH decoiler is suitable for various applications.

- Safety and Ease of Use: Features like the optional Hydraulic Loading Car simplify operations and improve workplace safety by reducing manual handling.

- Durability: Built to withstand demanding industrial environments, the MDH decoiler delivers long-term reliability and performance.

Built for Long-Term Performance

Morgan Rushworth is known for its commitment to quality and durability. The MDH Hydraulic Decoiler is no exception, featuring robust construction and high-quality components that ensure dependable performance over time. Regular maintenance and support from Morgan Rushworth further enhance the longevity of this machinery, providing businesses with a reliable solution for their coil handling needs.

Why Choose Morgan Rushworth?

With decades of experience in manufacturing industrial machinery, Morgan Rushworth is a trusted name in the industry. The MDH Hydraulic Decoiler reflects the company’s dedication to innovation, quality, and customer satisfaction. By choosing Morgan Rushworth, businesses can be confident in their investment, knowing they are getting a machine that combines advanced technology with user-friendly features.

Conclusion

The Morgan Rushworth MDH Hydraulic Decoiling Machinery is a high-performance solution designed to meet the demands of modern industry. With its impressive capacity range, innovative features, and optional Hydraulic Loading Car, the MDH decoiler offers unmatched efficiency, versatility, and reliability. Whether you are in automotive manufacturing, metal fabrication, or construction, this machinery is an invaluable asset that will optimise your operations and enhance productivity. For businesses looking to stay ahead in a competitive market, the MDH Hydraulic Decoiler is a smart and reliable investment.

![Morgan Rushworth Hydraulic Decoiler 006 [Web]](https://selmach.com/wp-content/smush-webp/2024/05/Morgan-Rushworth-Hydraulic-Decoiler-006-Web.png.webp)