Morgan Rushworth DFR 600 Flat Bed Deburring Machine 415V

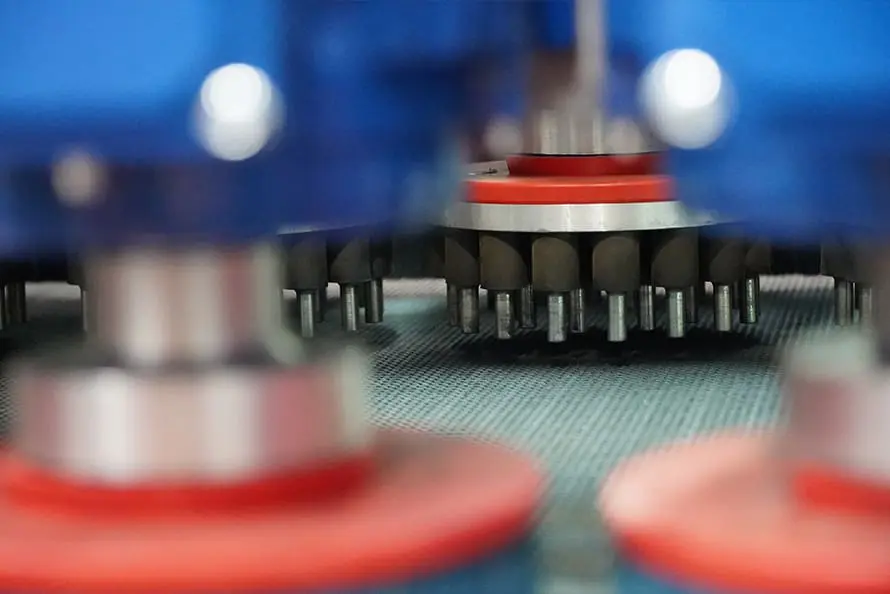

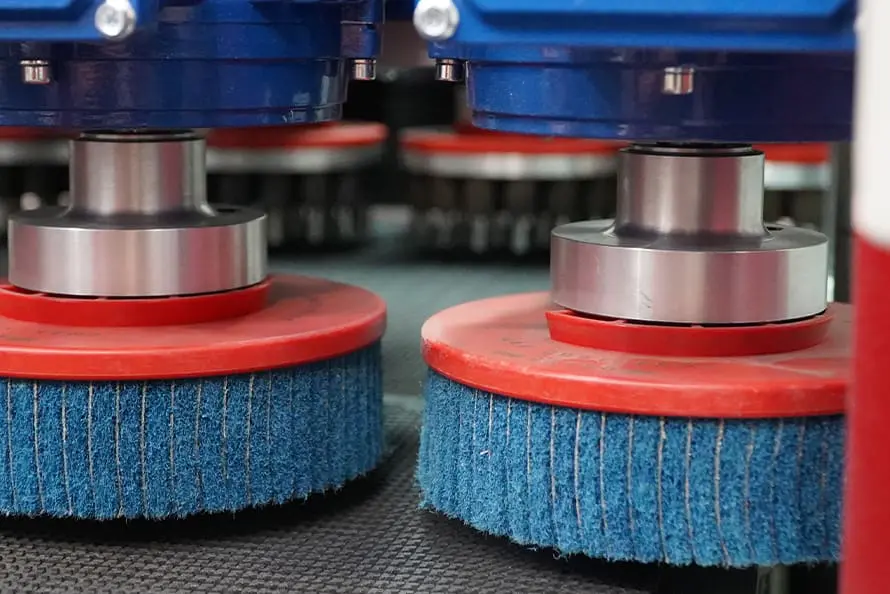

The Morgan Rushworth DFR 600 Flat Bed Deburring Machine 415V is a versatile solution for cleaning and finishing sheet metal after cutting processes. Equipped with two “Z” type machining units, it offers exceptional efficiency by performing two operations simultaneously. This capability makes it ideal for removing scale after plasma cutting or deburring and rounding edges after laser cutting in a single pass.

With a processing range accommodating thicknesses and widths up to 600 mm, the DFR 600 is suitable for small to medium-sized workpieces. When paired with appropriate tools, it excels in heavy edge rounding and oxide removal.

| MODEL | DFR 600 | |

| Max. Processing Width | mm | 600 |

| Table Length | mm | 1300 |

| Thickness Range | mm | 0.5 – 50 |

| Wheel Diameter | mm | 150 |

| Feed Speed | m/min | 0.5 – 2 |

| Deburring Wheels | 4 | |

| Length | mm | 1500 |

| Width | mm | 1100 |

| Height | mm | 1700 |

| Weight | kg | 1500 |

Features

- Descale, Deburr, Rounding, Oxide Removal and Polishing

- TFT Operator Panel

- Two pairs of oscillating wheels

- Variable speed conveyor

- Full enclosure with electrically interlocked doors

Options

- Abrasive de-burring and rounding wheels

- Beating and descaling wheels

- Flap discs for strong edge rounding

- Oxide removal discs

- Magnetic plate in the table

- Magnetic table (300mm Wide)

Morgan Rushworth DFR 600 Flat Bed Deburring Machine 415V

The Morgan Rushworth DFR 600 Flat Bed Deburring Machine 415V is a state-of-the-art solution tailored for cleaning, finishing, and preparing sheet metal surfaces after cutting processes. Its advanced engineering ensures seamless integration into workshops, catering to businesses prioritising efficiency and precision. With its robust build and innovative features, this machine is a must-have for industries handling small to medium-sized workpieces.

Dual “Z” Machining Units for Maximum Efficiency

At the heart of the DFR 600 is its dual “Z” type machining units, a standout feature that allows the machine to perform two operations simultaneously. This dual-action capability streamlines the finishing process by combining scale removal and edge rounding into a single pass. This makes it an invaluable asset for operations involving plasma-cut or laser-cut sheet metal, saving time and reducing labour costs.

Whether it’s heavy-duty deburring or precise edge rounding, the dual machining units ensure consistent, high-quality results. The versatility of these units also allows them to handle a variety of tasks, from oxide removal to creating smooth, uniform finishes.

Wide Processing Range for Diverse Applications

The DFR 600 is designed to accommodate workpieces of various sizes, with a processing range capable of handling thicknesses and widths up to 600 mm. This adaptability makes it suitable for a broad spectrum of applications, whether dealing with smaller intricate components or medium-sized sheets.

Industries requiring precise edge finishes, such as automotive, fabrication, or aerospace, will find the DFR 600 particularly beneficial. The machine’s ability to process materials efficiently ensures that businesses can meet demanding production schedules without compromising on quality.

Heavy Edge Rounding and Oxide Removal Capabilities

For businesses that rely on heavy edge rounding or require thorough oxide removal, the DFR 600 delivers exceptional performance. By pairing the machine with appropriate tools, users can achieve superior results, even on challenging materials. This capability is particularly advantageous for post-laser cutting operations, where clean, burr-free edges are essential for both aesthetic and functional purposes.

The machine is also well-suited for preparing metal surfaces for further treatments, such as painting or coating, ensuring optimal adhesion and a professional finish.

Simplified Operation and Maintenance

Ease of use is a key advantage of the DFR 600. Its intuitive controls and straightforward setup make it accessible to operators with varying levels of experience. The ergonomic design ensures comfortable operation, while the sturdy construction minimises vibration and noise, creating a more pleasant working environment.

Additionally, maintenance has been carefully considered in the machine’s design. Accessible components and high-quality materials reduce downtime and extend the overall lifespan of the equipment, making it a cost-effective choice for long-term use.

Compact Design for Space Efficiency

Despite its powerful capabilities, the DFR 600 boasts a compact design that ensures it can be easily integrated into workshops with limited space. Its efficient footprint does not compromise its functionality, making it an ideal choice for businesses of all sizes. The thoughtful layout of the machine’s components also facilitates easy access during operation and maintenance.

Applications Across Industries

The versatility of the Morgan Rushworth DFR 600 makes it an essential tool across a range of industries. From small fabrication shops to larger-scale manufacturing facilities, this machine is a reliable solution for enhancing productivity and improving the quality of finished products. Typical applications include:

- Automotive manufacturing: Creating smooth, rounded edges for safety and functionality.

- Metal fabrication: Preparing sheet metal for assembly or additional processing.

- Aerospace: Ensuring precise finishes on critical components.

Benefits of the DFR 600 Flat Bed Deburring Machine

The DFR 600 offers several distinct advantages for businesses seeking to enhance their production processes:

- Time-saving efficiency: By combining multiple operations in a single pass, the machine reduces production times significantly.

- Consistent quality: Achieve uniform results across a variety of materials and thicknesses.

- Reduced labour costs: Minimise manual intervention with automated finishing processes.

- Long-term durability: Built with high-quality materials to withstand the rigours of daily operation.

Enhancing Productivity with Morgan Rushworth

The Morgan Rushworth DFR 600 Flat Bed Deburring Machine 415V embodies a commitment to innovation and excellence in metal finishing solutions. Its advanced features and robust design make it a dependable choice for businesses aiming to achieve superior results while optimising their workflow.

Whether you’re looking to improve the finish on plasma-cut pieces or enhance the precision of laser-cut components, the DFR 600 provides a reliable, efficient, and cost-effective solution tailored to your needs.