Morgan Rushworth DFR 1350 Flat Bed Deburring Machine 415V

The Morgan Rushworth DFR 1350 Flat Bed Deburring Machine 415V is a durable and efficient solution for de-slagging and deburring profile-cut components. Capable of handling parts from 0–40mm thick and up to 1350mm wide, it ensures precise and consistent results across a range of applications.

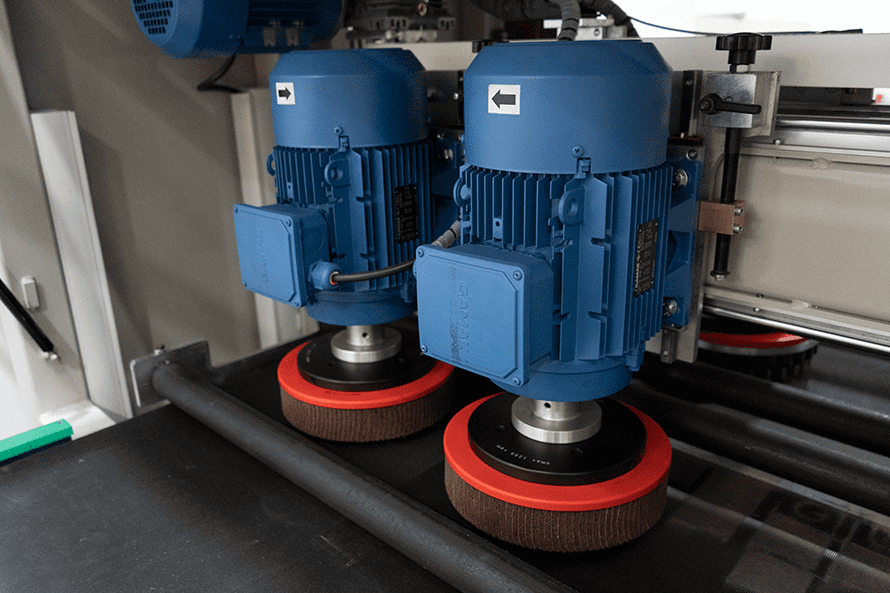

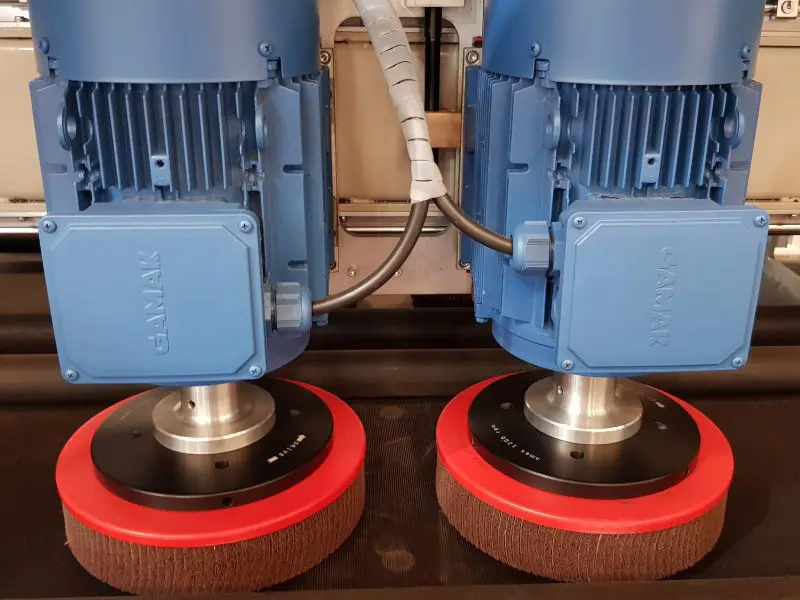

Equipped with a variable-speed conveyor and two pairs of oscillating wheels, the machine delivers flexible finishing options. Users can customise the process by selecting different grit abrasives for each wheel pair or opt for heavy-duty wheels to remove stubborn slag with ease.

| MODEL | DFR 1350 | |

| Max. Processing Width | mm | 1350 |

| Thickness Range | mm | 0 – 40 |

| Wheel Diameter | mm | 300 |

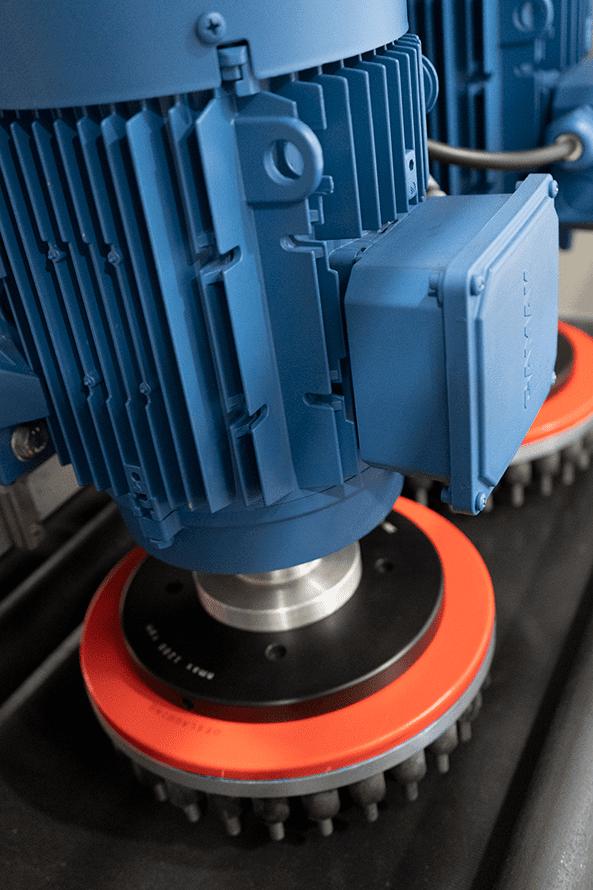

| Deburring Wheel Motor | kW | 4 x 22 |

| Conveyor Motor | kW | 1.1 |

| Height Adjustment Motor | kW | 1.1 |

| Length | mm | 1770 |

| Width | mm | 1850 |

| Height | mm | 1780 |

| Weight | kg | 1700 |

Features

- De-burring and de-slagging of profile cut plates

- Touch screen PLC control

- Motorised thickness adjustment

- Variable speed conveyor

- Two pairs of oscillating wheels

- Variable speed of rotation

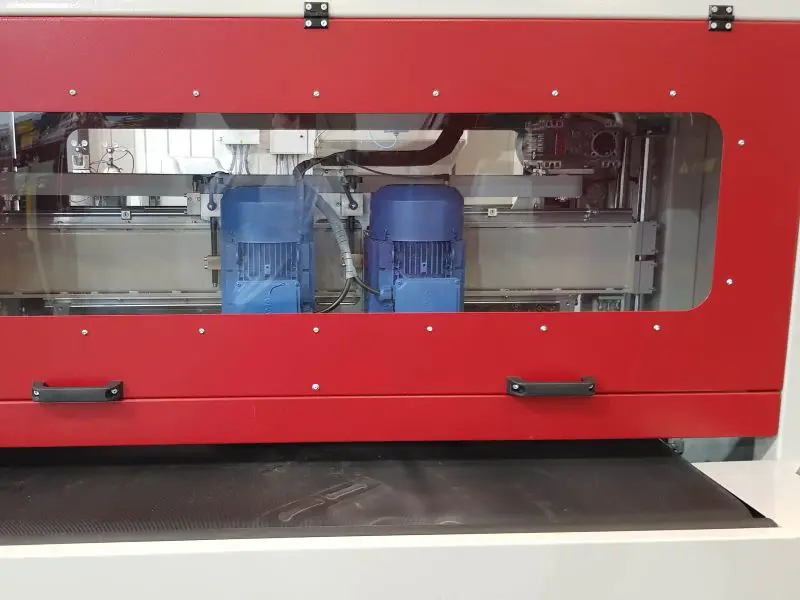

- Full enclosure with electrically interlocked doors

Options

- Abrasive de-burring wheels

- Heavy duty de-slagging wheels

Morgan Rushworth DFR 1350 Flat Bed Deburring Machine 415V

The Morgan Rushworth DFR 1350 Flat Bed Deburring Machine 415V is a robust and highly efficient solution for de-slagging and deburring profile-cut parts. Engineered for precision and versatility, this machine is ideal for workshops and manufacturing facilities that prioritise quality and efficiency in their metal finishing processes. Its advanced design and durable components make it a cost-effective choice for achieving smooth, burr-free surfaces across a wide range of applications.

Wide Processing Capabilities for Diverse Applications

The DFR 1350 is designed to handle a wide range of workpieces, accommodating parts with thicknesses from 0–40mm and widths of up to 1350mm. This broad processing capability ensures that the machine can manage everything from thin sheet metal to thicker, more substantial components.

Its versatility makes it an ideal choice for various industries, including fabrication, automotive, and aerospace, where precise finishes are essential for both aesthetic and functional purposes. Whether dealing with small-scale production or larger-scale operations, the DFR 1350 delivers consistent and reliable results.

Oscillating Wheels for Precise Deburring

A standout feature of the DFR 1350 is its dual pairs of oscillating wheels, which perform the critical deburring action. These wheels are designed to work in unison, ensuring a smooth and even finish on all edges. The oscillating motion enhances the deburring process by evenly distributing the abrasive action across the workpiece, reducing the risk of uneven finishes or missed areas.

To further enhance its versatility, the machine allows users to customise the deburring process by utilising different grit abrasives on each set of wheels. This flexibility ensures that the machine can deliver the desired finish, whether it’s a fine polish for cosmetic purposes or a more aggressive grind for heavy-duty applications.

Heavy-Duty Deburring for Slag Removal

For tasks that require the removal of heavy slag, the DFR 1350 is equipped to handle the challenge. Optional heavy-duty deburring wheels are available, enabling the machine to tackle stubborn and thick deposits left after cutting processes such as plasma or oxy-fuel cutting. These wheels ensure a clean and smooth finish, preparing the metal surface for further processing, coating, or assembly.

This capability makes the DFR 1350 an essential tool for workshops handling high-volume or heavy-duty metal fabrication projects.

Adjustable Speed Conveyor for Optimised Workflow

The machine features a variable-speed conveyor system, which is designed to move workpieces through the machine at the optimal pace for each specific task. This adjustable speed not only improves the efficiency of the deburring process but also allows operators to fine-tune the machine’s performance based on the material being processed and the desired finish.

The conveyor ensures consistent contact between the workpiece and the oscillating wheels, delivering uniform results across all surfaces. This system also minimises the need for manual intervention, reducing labour costs and improving overall productivity.

User-Friendly Design for Easy Operation

Ease of use is a key advantage of the DFR 1350 Flat Bed Deburring Machine. The intuitive controls and straightforward setup make it accessible to operators of all skill levels. The ergonomic design ensures comfortable operation, while the robust construction minimises vibration and noise, creating a safer and more pleasant working environment.

Maintenance requirements have also been thoughtfully addressed in the machine’s design. Accessible components and high-quality materials reduce downtime, ensuring that the machine remains in optimal condition for years of reliable use.

Compact yet Powerful

Despite its impressive capabilities, the DFR 1350 is designed with a compact footprint, making it suitable for workshops with limited space. Its efficient layout does not compromise on performance, ensuring that it can deliver powerful results even in smaller facilities. This combination of power and space efficiency makes it an ideal choice for businesses of all sizes.

Versatility Across Industries

The Morgan Rushworth DFR 1350 is a valuable asset across a wide range of industries. Its ability to handle different materials and finishes ensures that it can meet the diverse needs of various sectors, including:

- Automotive: Preparing components with smooth, burr-free edges for assembly or coating.

- Fabrication: Removing slag and burrs from structural elements and sheet metal parts.

- Aerospace: Achieving precision finishes on critical components where accuracy is essential.

- General engineering: Providing consistent results for a variety of metalworking applications.

Key Benefits of the Morgan Rushworth DFR 1350

The DFR 1350 Flat Bed Deburring Machine offers several advantages that make it an invaluable tool for metal finishing:

- Versatile processing: Handles a wide range of part sizes, thicknesses, and materials.

- Efficient operation: Dual oscillating wheels and variable-speed conveyor ensure fast and consistent results.

- Customisable finishes: Use different grit abrasives or heavy-duty wheels to achieve the desired outcome.

- Durability: Built with high-quality components to withstand the demands of daily use.

- Cost-effective: Reduces labour costs and minimises downtime, providing long-term savings.

Conclusion: A Reliable Solution for Metal Finishing

The Morgan Rushworth DFR 1350 Flat Bed Deburring Machine 415V is a versatile, reliable, and efficient solution for removing slag, burrs, and imperfections from profile-cut parts. With its advanced features, user-friendly design, and robust construction, it delivers exceptional performance for a wide range of applications.

Whether you need to prepare metal for further processing, coating, or assembly, the DFR 1350 offers a cost-effective and powerful solution tailored to meet the needs of modern workshops and manufacturing facilities.

Alternatively, check out our range of Polishing & Deburring Machinery