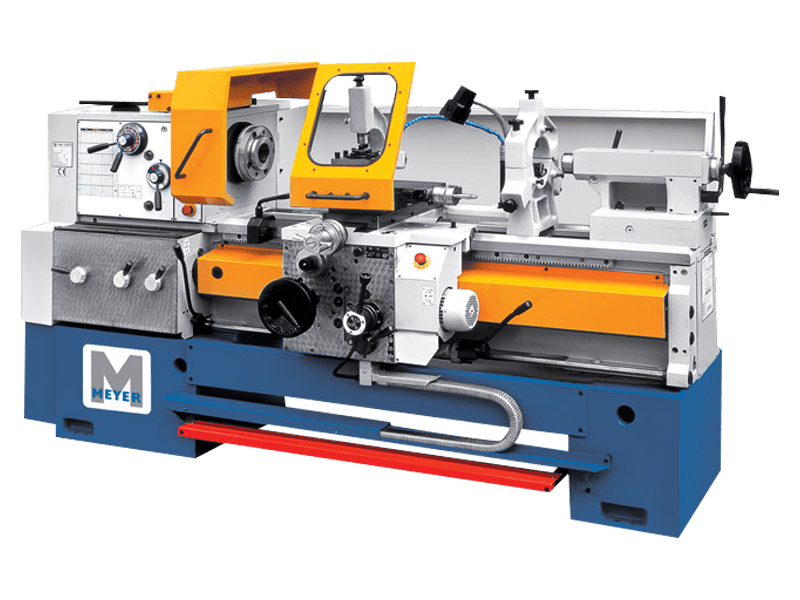

Meyer Euroline ER Precision Centre Lathes

The Meyer Euroline ER precision centre lathes are engineered for durability and high performance. Manufactured in Europe with premium materials and rigorous quality controls, these machines are ideal for a wide range of machining tasks. Their robust construction ensures reliable operation even under heavy-duty conditions.

The ER and ES models range from compact tool room lathes with a 325mm swing over bed and 500mm between centres to larger models with a 600mm swing over bed and up to 5 metres between centres. Thread cutting capabilities include metric, imperial, module, and diametric pitches, with optional variable-speed configurations available.

| ER 325/500

ER 325/700 ER 325/1000 |

ER 400/750

ER 400/1000 ER 400/1500 |

ER 440/1000

ER 440/1500 ER 440/2000 |

ER 500/1000

ER 500/1500 ER 500/2000 |

||

| Capacities | |||||

| Height of centres | mm | 165 | 200 | 210 | 245 |

| Swing over Bed | mm | 325 | 400 | 440 | 500 |

| Swing over cross slide | mm | 190 | 235 | 230 | 300 |

| Swing in gap* | mm | 440 | 550 | 620 | 670 |

| Width of bed | mm | 200 | 320 | 360 | |

| Distance between Centres | mm | 500 – 750 – 1000 | 750 – 1000 – 1500 | 1000 – 1500 – 2000 | |

| Spindle | |||||

| Spindle nose DIN 55027 | No | 5 | 6 | 8 | |

| Spindle bore | mm | 32 | 52 | 62 | |

| Spindle taper | Metric | No. 4.5 | 6 | 80 | |

| Headstock | |||||

| Number of spindle speeds | – | 12 (24) | 12 | 21 | |

| Spindle speed ranges | rpm | 85 – 2000 (42.5 – 2000)** | 50 – 2240 | 20 – 2000 | |

| Main motor power | kW | 2.2 | 4 | 7.5 (11) | |

| Feeds | |||||

| Number of feeds | – | 48 | 80 | 120 | |

| Longitudinal feed range | mm/rev | 0.006 – 1.77 | 0.015 – 0.6 | 0.04 – 12 | |

| Cross feed range | mm/rev | 0.003 – 0.885 | 0.0075 – 0.3 | 0.02 – 6 | |

| Threads | |||||

| Number of threads | – | As below | 40 of each kind | 64 of each kind | |

| Metric thread range | mm | (48) 0.1 – 28 | 0.25 – 7.5 | 0.5 – 120 | |

| Inch thread range | Tpi | (53) 75 – 2.5 | 120 – 4 | 60 – 1/4 | |

| Module thread range | Module | (19) 0.1 – 1.75 | 0.0625 – 1.875 | 0.125 – 30 | |

| DP thread range | DP | (19) 70 – 4 | 480 – 16 | 240 – 1 | |

| Carriage | |||||

| Cross slide travel | mm | 150 | 235 | 250 | |

| Top slide travel | mm | 95 | 110 | 130 | |

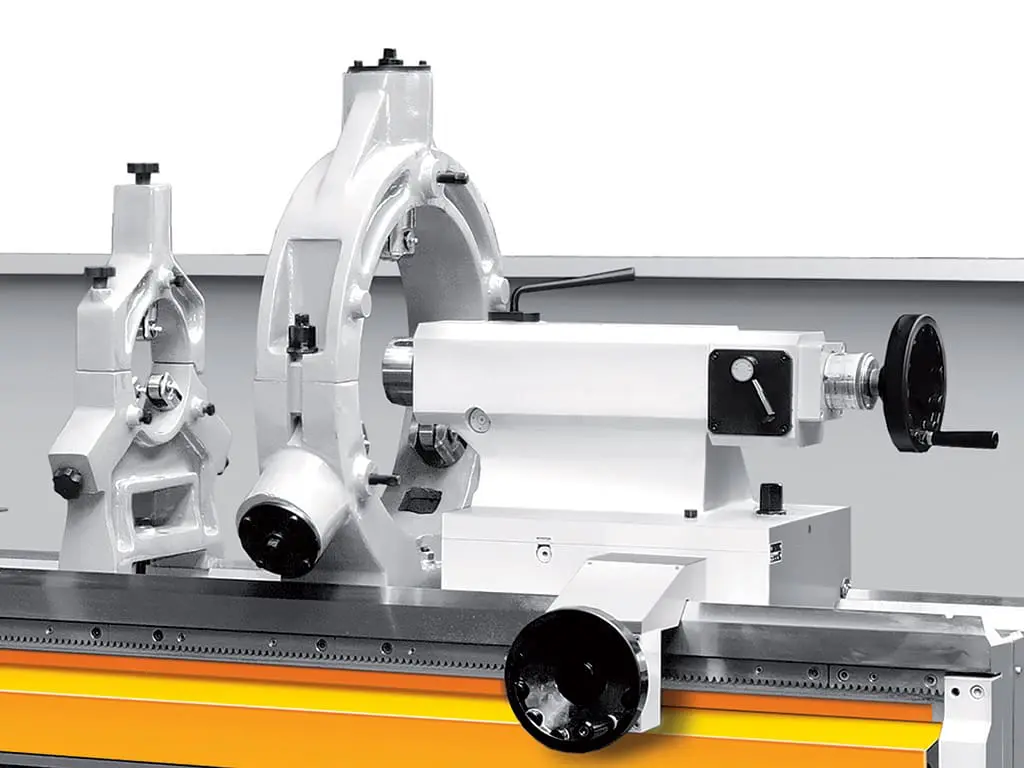

| Tailstock | |||||

| Quill diameter | mm | 40 | 60 | 70 | |

| Quill taper | Morse | No.3 | No.4 | No.5 | |

| Quill travel | mm | 100 | 100 | 180 | |

| Dimensions | |||||

| Length | mm | 1750 – 2300 | 2500 – 3250 | 2290 – 3900 | 2900 |

| Width | mm | 1000 | 1100 | ||

| Height | mm | 1550 | 1600 | 1700 | 1750 |

| Weight | kg | 770 | 1700 | 2560 | 2630 |

* With option machine bed gap ** Only for two-speed motor execution

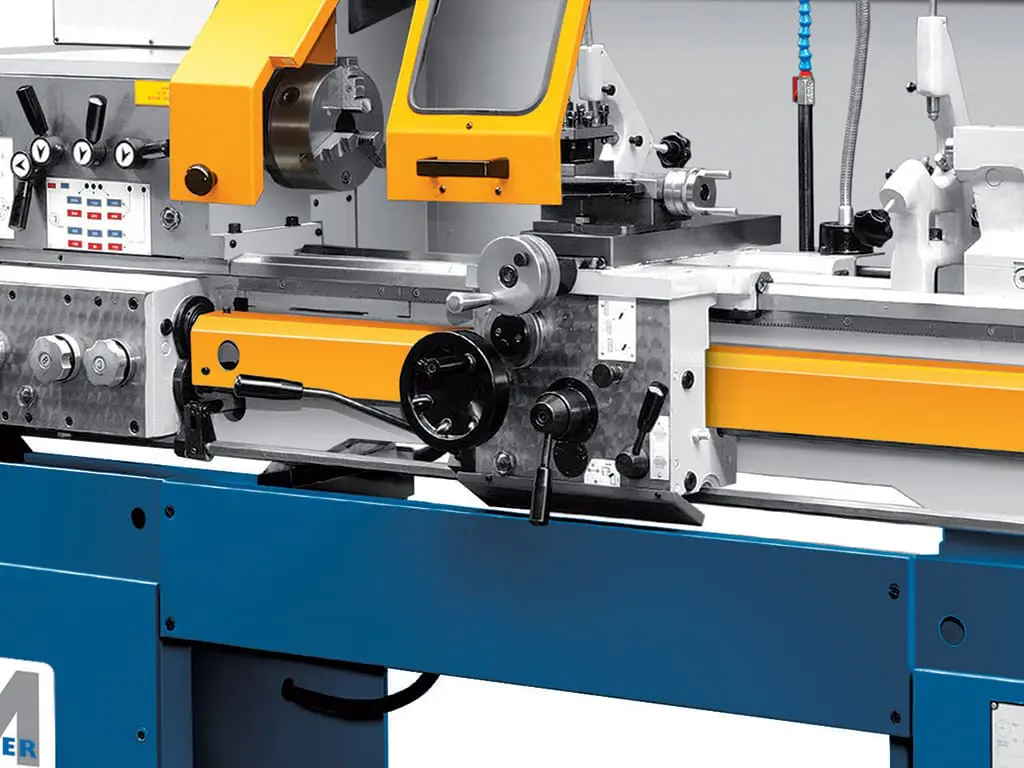

Features

- High quality European built machines

- Rigid build ensures high chip removal rate during the rough turning operation

- Highly resistant steel with high loading capacity used for all gear and spindle parts

- Cast bed with hardened and ground bed ways

- Four position square toolpost

- Chuck guard with interlock switch

- Lead screw guard

- Low voltage halogen work light

- Centralised lubrication

- Chip collection tray

- Coolant system

- Full length rear splash guard

Options

- Variable spindle speed

- 2 or 3 axis digital read out

- Thread dial indicator

- Quick change tool post

- 3 and 4 jaw chucks

- Face plate

- Fixed steady

- Follow rest

Meyer Euroline ER Precision Centre Lathes

The Meyer Euroline ER range of precision centre lathes is a benchmark in the machining industry, offering durability, precision, and versatility. Manufactured in Europe, these lathes are built with premium materials and undergo stringent quality control processes. Designed for a variety of machining tasks, their robust construction ensures reliable performance even under heavy-duty conditions.

Comprehensive Range of Models

The ER and ES models cover a broad spectrum of applications. Starting with the compact tool room lathe, these models feature a 325mm swing over bed and 500mm between centres, perfect for smaller precision tasks. At the other end of the range, larger models offer a 600mm swing over bed and up to 5 metres between centres, making them ideal for handling large and complex workpieces. This versatility makes the ER series suitable for workshops of all sizes and industries with diverse machining requirements.

Advanced Thread Cutting Capabilities

Thread cutting is a standard feature across all Meyer Euroline ER lathes. These machines support a wide variety of threading options, including metric, imperial, module, and diametric pitches. This range ensures compatibility with a broad array of threading applications, whether for industrial machinery, automotive components, or custom engineering projects. The precision and reliability of the threading system allow for consistently accurate results.

Variable-Speed Configurations

For enhanced operational flexibility, many models in the ER series can be supplied with an optional infinitely variable-speed configuration. This feature includes multiple sub-ranges, allowing operators to fine-tune the lathe’s performance to match specific materials and machining tasks. The ability to adjust speeds ensures optimal results, whether working with softer metals or harder, more challenging materials.

European Craftsmanship and Quality

The Meyer Euroline ER lathes are manufactured in Europe, adhering to the highest standards of craftsmanship and engineering excellence. The use of premium materials ensures durability and long-term reliability, while rigorous quality control processes guarantee that each machine meets strict performance criteria. This commitment to quality makes the ER series a trusted choice for professionals seeking dependable machining solutions.

Designed for Durability and Performance

The robust construction of the ER range is a key factor in its exceptional performance. Heavy-duty components and precision engineering combine to deliver machines that can handle demanding tasks with ease. The ergonomic design of the lathes ensures operator comfort and efficiency, while thoughtful placement of service points simplifies maintenance and reduces downtime.

Key Features of the ER Range

- Swing Over Bed: Models available with 325mm to 600mm swing over bed

- Distance Between Centres: Options ranging from 500mm to 5 metres

- Thread Cutting: Supports metric, imperial, module, and diametric pitches

- Variable-Speed Configurations: Optional feature with multiple sub-ranges

- European Manufacturing: Premium materials and rigorous quality control

These features highlight the versatility and capability of the Meyer Euroline ER series, catering to a wide range of machining needs.

Applications Across Industries

The adaptability of the ER lathes makes them suitable for a variety of industries, including automotive, aerospace, and general engineering. Their ability to handle both small-scale precision tasks and large-scale projects ensures they can meet the demands of any workshop. The advanced threading capabilities and optional variable-speed configurations further enhance their appeal, providing the flexibility needed for specialised applications.

Exceptional Value and Support

Investing in the Meyer Euroline ER range means choosing a machine that delivers exceptional value over its operational lifespan. With reliable performance, minimal maintenance requirements, and a strong focus on durability, these lathes represent a cost-effective solution for businesses. Additionally, Meyer Euroline offers comprehensive customer support, including installation assistance, training, and after-sales service, ensuring a seamless ownership experience.

Conclusion

The Meyer Euroline ER Precision Centre Lathes set the standard for quality, performance, and adaptability in the machining industry. From their robust construction and advanced features to their extensive range of models, these machines are designed to meet the diverse needs of professionals across various sectors. With European craftsmanship at their core, the ER lathes are a reliable and versatile addition to any workshop, providing exceptional results and long-term value.