The metal slats in a fibre laser cutting machine are a critical part of the cutting process, supporting the workpiece during operation. Over time, these slats accumulate molten material, known as dross or slag, which can have a significant impact on cut quality, machine performance, and component lifespan.

Regular inspection, cleaning, or replacement of slats is essential to maintain consistent production quality, avoid unplanned downtime, and protect high-value components in the laser system.

Back Reflections and Optics Damage

Dross build-up on slats can cause laser light to reflect back towards the cutting head. These back reflections may damage the protective lens, nozzle, fibre delivery system, and in severe cases, the cutting head itself. If the protective lens becomes contaminated, it may need to be replaced after as little as one sheet of material, quickly increasing your operating costs and eroding any profitability in the job through the cost of the lens and the downtime to exchange it.

If the tips of the slats are particularly worn, the focal point of the laser can be completely misaligned with the surface of the material, even within the usual tolerance of the torch.

Reduced Cutting Quality

Uneven or contaminated slats disrupt the stable support of the sheet, leading to inconsistent cut height. This results in increased burrs, rough edges, and poor cut accuracy, often requiring additional finishing or scrapping of parts..

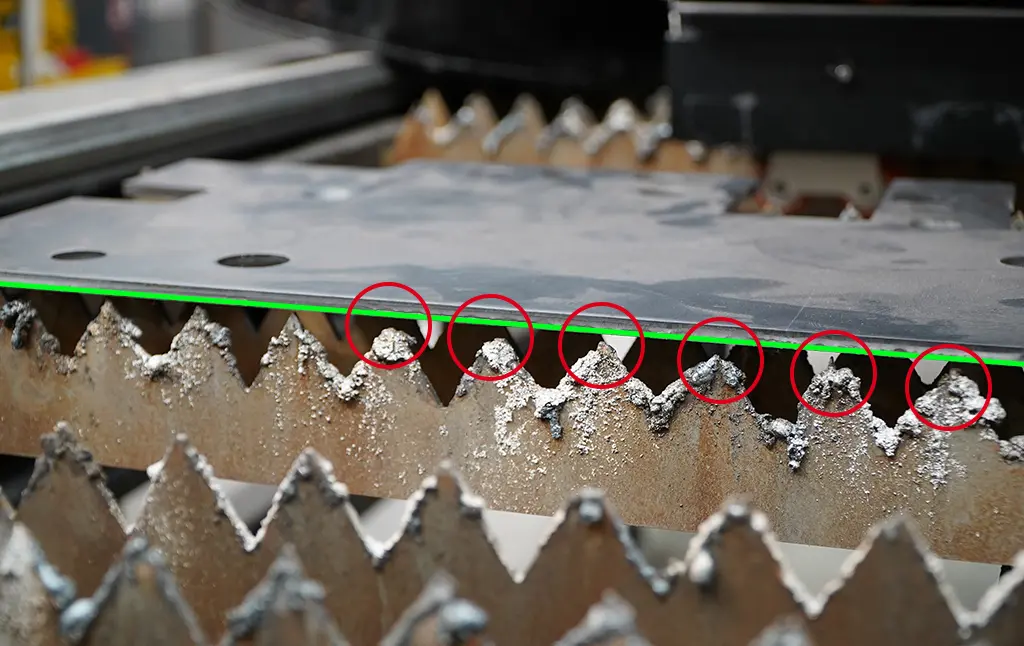

Dross build-up can cause back-reflections towards the torch, damaging protective lens or the torch head itself.

Increased Vibrations

When slats are uneven or clogged with slag, the workpiece may vibrate during cutting. Even minor vibrations can produce irregularities in the kerf width and reduce overall cut precision. This is especially prominent when cutting with high pressure nitrogen.

Workpiece Not Sitting Flat

A flat support surface is vital for consistent focus. When slag build-up prevents the sheet from sitting evenly, focal distance changes across the sheet, compromising the quality of the cut; particularly on thin materials.

Here there are six tips in a row that are below the height of the material surface, which can result in material distorting when cutting.

Increased Risk of Collisions

Small parts cut from a sheet are more likely to tip or catch on slag, increasing the chance of nozzle collisions. These incidents can damage the torch, disrupt the cutting process, and create additional downtime while being rectified.

Deformation of Larger Parts

Larger sheets or components are especially prone to distortion if they are not supported evenly. Thermal movement during cutting can combine with uneven support to cause warping, bending, or dimensional inaccuracies.

Excessive melting of the tips means they will lose their overall profile.

Best Practices for Slat Maintenance

-

Regular Inspection: Frequently check for slag build-up, bends, or wear.

-

Purpose-Built Cleaning Tools: Use dedicated equipment such as the Morgan Rushworth Slat Cleaning Machine to remove slag quickly and efficiently without damaging the slats.

-

Scheduled Replacement: Replace slats when cleaning is no longer effective or when they are visibly damaged. Slats should be replaced on a schedule where possible.

- Preventative Measures: Anti-spatter sprays can help reduce slag adhesion but should be used alongside a regular cleaning schedule.

The Operational Benefits of Proper Slat Maintenance

Maintaining clean, even slats in your fibre laser cutting machine protects your optics, extends consumable lifespan, reduces the risk of collisions, and ensures consistent cut quality. It also minimises rework, scrap material, and downtime, helping you keep production running efficiently. Machines that are well maintained should be able to keep using the same protective lens for months at a time without the need for replacement. If you’re having to replace lens regularly, the quality of your slats could be one factor to consider.

For advice on slat maintenance, or to find the right cleaning solution for your machine, contact Selmach Machinery or view our Morgan Rushworth Slat Cleaning Machine for a purpose-built, cost-effective solution.

Published 12th August 2025