Modern fabrication machinery is remarkably capable; CNC lasers, press brakes, bandsaws and drilling equipment routinely achieve tolerances that would have been considered laboratory-grade engineering a generation ago. Yet in workshops across the country, many repeated breakdowns don’t come from design flaws, operator misuse, or even workload intensity.

They come from maintenance shortcuts. Almost every recurring fault our service engineers investigate traces back to one of the following ten habits. Individually they seem minor, but collectively they can destroy reliability, accuracy, and component life.

Below is a practical breakdown of the most common maintenance mistakes — and why they lead to repeat failures.

1. Skipping Preventive Maintenance

Preventive maintenance is often the first casualty of a busy production schedule. Machines appear to be running fine, so those planned checks are postponed “until next week”, when you’re less busy.

The problem is that most mechanical failures are progressive, not sudden, also that next week becomes busy so it’s pushed back another week, and so on and so forth.

Some examples:

- A slightly contaminated coolant system → overheated bandsaw blades → accelerated blade wear and chipped teeth

- A loose bearing → vibration → encoder misreading → positioning faults

- A blocked filter → overheating → drive failure

By the time the machine stops, the original cheap issue (such as replacing coolant) has cascaded into multiple expensive ones.

Preventive maintenance isn’t just about avoiding breakdowns entirely — it’s about catching faults while they are still single-component problems rather than system-wide failures.

Structured service intervals dramatically reduce unplanned downtime because faults are intercepted before they propagate through the machine.

For more information on scheduled maintenance, check out our dedicated blog.

2. Ignoring OEM Recommendations

Manufacturers specify service intervals, oil grades, tolerances, and procedures for a reason: machines are engineered around those parameters, and work best within them.

A hydraulic press brake designed for ISO VG 46 oil will still move on VG 68, but it won’t move correctly – Viscosity affects valve timing, heat dissipation, and servo accuracy.

Similarly:

-

The wrong grease changes bearing preload behaviour

-

Non-approved coolant alters corrosion resistance

-

Incorrect torque settings distort frame alignment

Ignoring OEM guidance doesn’t cause immediate failures. But it causes slow geometric drift and component stress — which shows up months later as unexplained accuracy issues or repeated electrical faults.

3. No Proper Records & Documentation

A surprising number of workshops rely on memory rather than maintenance records.

“Did we change that filter?”

“I think the oil was topped up last year.”

“That drive fault happened before, didn’t it?”

Without documentation, engineers cannot diagnose trends.

Recurring faults often aren’t identical failures, they’re patterns.

For example:

-

Three motor failures in two years → actually caused by overheating due to blocked ventilation

-

Repeated blade snapping → actually incorrect feed calibration

-

Servo alarms returning → actually progressive mechanical resistance

Maintenance logs allow cause and effect to be identified. Without them, every repair becomes isolated guesswork — which leads to repeated downtime.

4. Using Wrong or Non-OEM Spare Parts

Not all spare parts are equal — even when they physically fit.

Metalworking machinery relies heavily on interaction between components:

-

Bearings and shafts

-

Guides and rails

-

Valves and seals

-

Sensors and control tolerances

Pattern parts often differ microscopically in hardness, surface finish, or tolerance stack-up. The machine runs, but forces are redistributed elsewhere.

Typical results:

-

Drives working harder than designed

-

Premature seal failure

-

Vibrations triggering control faults

-

Accuracy drifting out of calibration

The real damage is cumulative. Each incorrect component adds stress to another system until something unrelated fails.

Using correctly specified spare parts preserves the mechanical balance the machine was designed around.

Here at Selmach we carry stock of over £250,000 of spare parts, with direct OEM partner links for other major component brands, we can source the correct parts for your machine, and even have some spare parts available to purchase on our Selmach Tooling Website too.

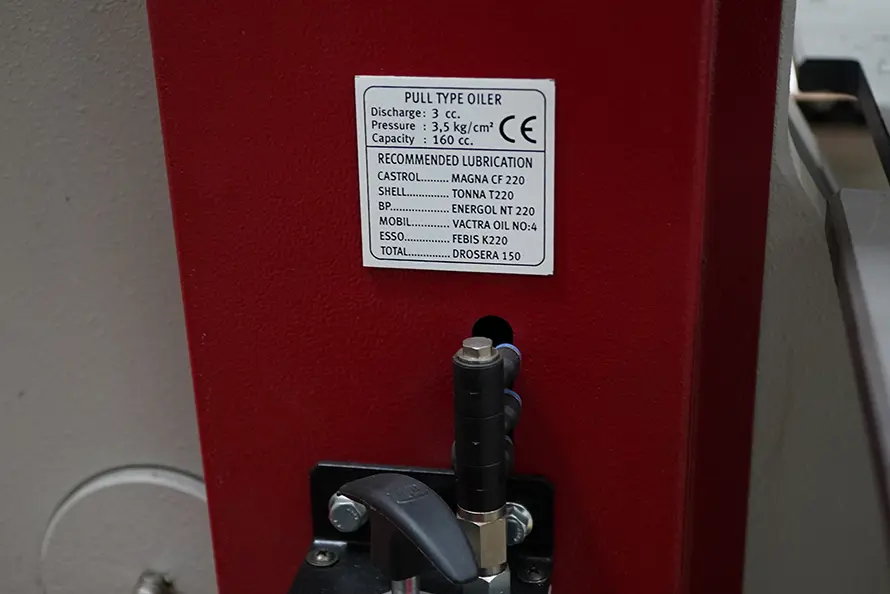

5. Improper Lubrication

Lubrication errors rarely look dramatic, they look harmless, however they can cause machine’s damage if done incorrectly.

- Too little oil causes wear.

- Too much oil causes heat.

Wrong oil causes both.

Machines fail not from friction alone, but from heat cycling and material fatigue. A linear guide running dry doesn’t seize instantly; it micro-pits. That pitting alters motion resistance, which the servo compensates for, increasing current draw, increasing temperature, shortening motor life.

Months later, the electrical fault appears unrelated.

In reality the root cause was lubrication quality.

Common lubrication mistakes:

-

Mixing grease types

-

Using general-purpose oil in precision systems

-

Failing to clean old lubricant contamination

-

Not purging lines after refilling

Lubrication is not a background task, it is the machine’s thermal management system.

6. Overriding Safety Alarms

Every engineer has heard it:

“Just reset it — it always does that.”

Alarms are often treated as nuisances when production pressure is high. However, modern machines monitor load, position resistance, thermal drift, and electrical behaviour through safety logic.

Many alarms are early warnings of potential mechanical stress.

Repeatedly overriding them converts a protective shutdown into continuous damage.

Examples:

-

Axis overload alarm → mechanical binding → ball screw failure

-

Overtemperature alarm → cooling blockage → drive burnout

-

Pressure alarm → seal degradation → hydraulic contamination

Alarms are diagnostic information, not inconveniences. Ignoring them removes the machine’s ability to protect itself. Would you ignore a flat tyre warning in your car and continue driving?

7. Poor Root Cause Analysis

Replacing the failed part is not necessarily fixing the problem — it is resetting the countdown.

True reliability comes from understanding why the part failed.

Without proper root cause analysis, maintenance becomes cyclical:

Replace relay → relay fails again

Replace bearing → bearing fails again

Replace sensor → sensor fails again

The machine is communicating through its failures.

If the initial cause isn’t identified, the same stress conditions remain.

Good analysis looks upstream:

-

Was the component overloaded?

-

Was the environment incorrect?

-

Was alignment drifting?

-

Was heat building gradually?

Structured fault investigation significantly reduces repeat callouts because the source condition is corrected rather than the symptom.

8. Rushed “Band-Aid” Fixes

Temporary fixes are sometimes necessary to keep production moving when the pressure is on. The issue is when a temporary fix inadvertently becomes permanent.

Common examples:

-

Bridged wiring instead of tracing intermittent faults

-

Shimming instead of correcting alignment

-

Manual parameter tweaks instead of recalibration

-

Sealant instead of replacing seals

These fixes alter system behaviour. The machine compensates, but compensation means stress redistribution.

The machine may run again quickly, but hidden load paths form. Later failures then appear unrelated and more expensive.

The cost of the original repair multiplies over time if not rectified.

9. Lack of Training

Even well-designed equipment cannot perform correctly if operators and maintenance teams don’t understand its behaviour.

Modern machinery integrates mechanics, hydraulics, electronics, and software control. A minor change in one system affects others.

Typical training-related failures:

-

Incorrect datum setting causing crashes

-

Manual overrides altering calibration references

-

Cleaning methods damaging sensors

-

Incorrect warm-up procedures causing thermal distortion

- Improper calibration causing a laser head torch collision

Training doesn’t just prevent operator damage, it preserves accuracy and component lifespan by ensuring the machine runs within its design envelope. It also ensures your operators are using the machine efficiently too, getting the most out of your investment.

If your operators need more training, reach out to our Service Team.

10. Skipping Calibrations & Inspections

Machines don’t suddenly go out of tolerance, they drift gradually.

- A press brake gradually bends 0.3° off angle

- A saw gradually cuts 0.5 mm out

- A laser gradually loses kerf consistency

Operators compensate manually to maintain output quality. Eventually adjustments reach limits, tooling breaks, or parts become scrap.

Regular calibration resets the machine’s reference geometry before compensation masks the issue.

Skipping calibration causes:

-

Hidden mechanical wear

-

Overloaded motors compensating for resistance

-

Tool damage

-

Repeated alignment faults

- Lost time from inefficient operations – costing the business money

Inspection isn’t just about paperwork, it is about preventing progressive mechanical distortion from becoming catastrophic failure. Through inspections and observations, you can see problems as they begin to appear, rather than when they’ve rendered the machine out of action.

Final Thoughts

Most repeated machinery breakdowns are not random events. They are the end result of small decisions accumulating over time.

- Maintenance done reactively treats machines like consumables.

- Maintenance done systematically treats them like precision instruments.

The difference is measured not just in repair costs, but in uptime, accuracy, and operator confidence.

Reliable production is rarely achieved through better machines alone — it comes from consistent maintenance discipline, proper parts selection, and structured service support.

More information on service support:

https://selmach.com/service/

Spare parts availability:

https://selmachtooling.co.uk/product-category/spare-parts/

Published 11th February 2026