Setting up a new bandsaw requires careful handling and precision to ensure optimal performance and safety. Follow these steps to properly set up your bandsaw and get it ready for use.

Step 1: Unloading and Removing from the Pallet

Once your bandsaw arrives, follow the manufacturer’s instructions (provided in the user manual) to safely remove the machine from the pallet or wooden bearers it arrived on. The manual includes specific details for lifting and handling, ensuring that your bandsaw remains stable and undamaged during setup.

Step 2: Unwrapping and Organising Loose Items

After safely removing the machine from its packaging, unwrap any protective plastic covering. Take out all loose items included, such as coolant trays, coolant, spare blades, and any detachable infeed or outfeed components. Set these aside in a clean, accessible area, as you’ll need them later in the setup process.

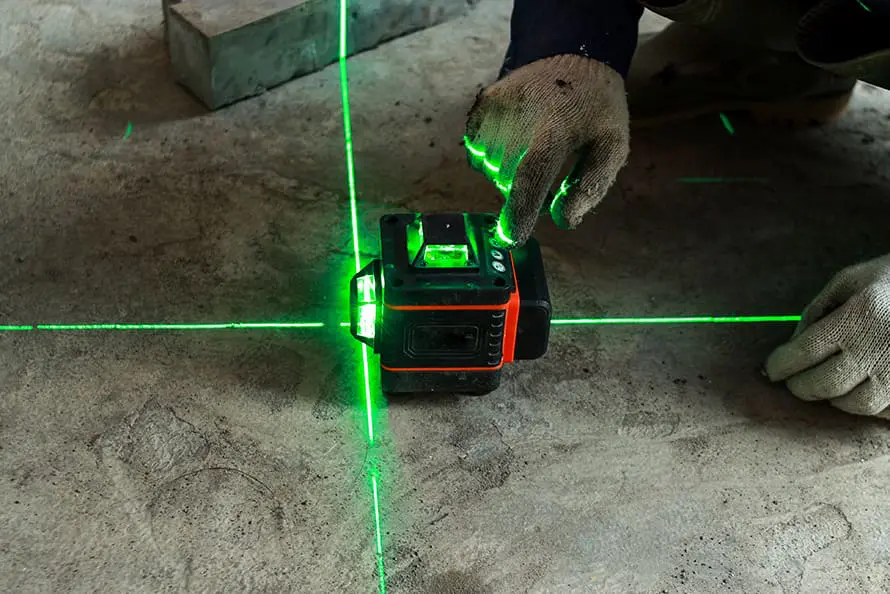

Step 3: Positioning and Levelling the Bandsaw

Using a laser level, position and level the bandsaw in its designated location. Ensuring that the machine is level is essential for precision cutting and safe operation. Once positioned, secure the bandsaw to the floor according to the manufacturer’s instructions.

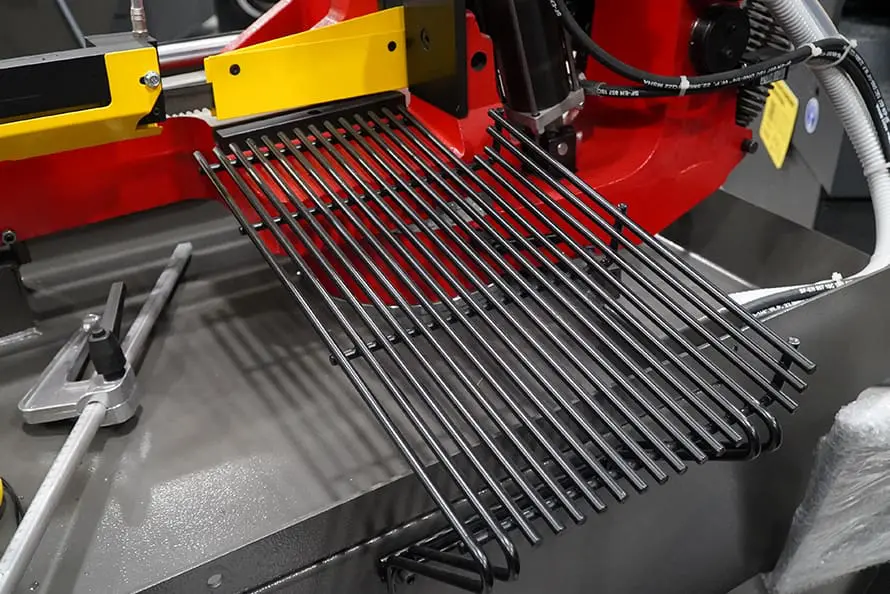

Step 4: Installing Roller Tracks or Measuring Systems

If your setup includes a roller track or measuring system, now is the time to install these components. Position the roller track so that it’s level with the bed height of the bandsaw, ensuring smooth, accurate material feeding during operation. Proper alignment of these components will enhance efficiency and cutting accuracy.

Step 5: Installing Coolant Trays and Detachable Components

Once the machine and any additional systems are securely fixed in place, install the coolant tray, infeed, outfeed, and any other detachable components that were included with the saw. This setup provides support and coolant for the bandsaw, ensuring optimal cutting performance and blade longevity.

Step 6: Adding Coolant to the Sump

Fill the saw’s sump with coolant as specified in the user manual. Adequate coolant levels are critical to maintaining proper blade temperature and preventing overheating during prolonged cutting sessions.

Step 7: Checking Blade Tension

Before operating the bandsaw, check that the blade is correctly tensioned. Refer to the user manual for the recommended tension settings specific to your model. Proper blade tension is essential for achieving clean, accurate cuts and preventing blade wear.

Step 8: Familiarising Yourself with the User Manual

Take time to read through the remainder of the user manual to ensure you’re fully informed about the saw’s operation. Understanding the controls, safety features, and recommended maintenance practices will help you use the saw safely and efficiently.

Step 9: Powering Up the Bandsaw

With everything in place, you’re now ready to power up the machine. If any issues arise during start-up, they may be related to phase rotation. Check the leaflet included with the machine, as it contains guidance on correcting phase rotation issues.

For any setup concerns or if you need further assistance, please contact our service team at 01432 346 555. Our experts are here to help ensure that your new bandsaw is set up and running smoothly.

Published 12th November 2024