Speed and consistency are two of the biggest challenges in metal fabrication. Whether you work with round tube, box section, angle, channel or custom profiles, traditional cutting methods often struggle to keep up with demand. Bandsaws, Circular saws, drills, grinders and notching tools all play a role; but each adds time, labour, material handling and opportunities for error.

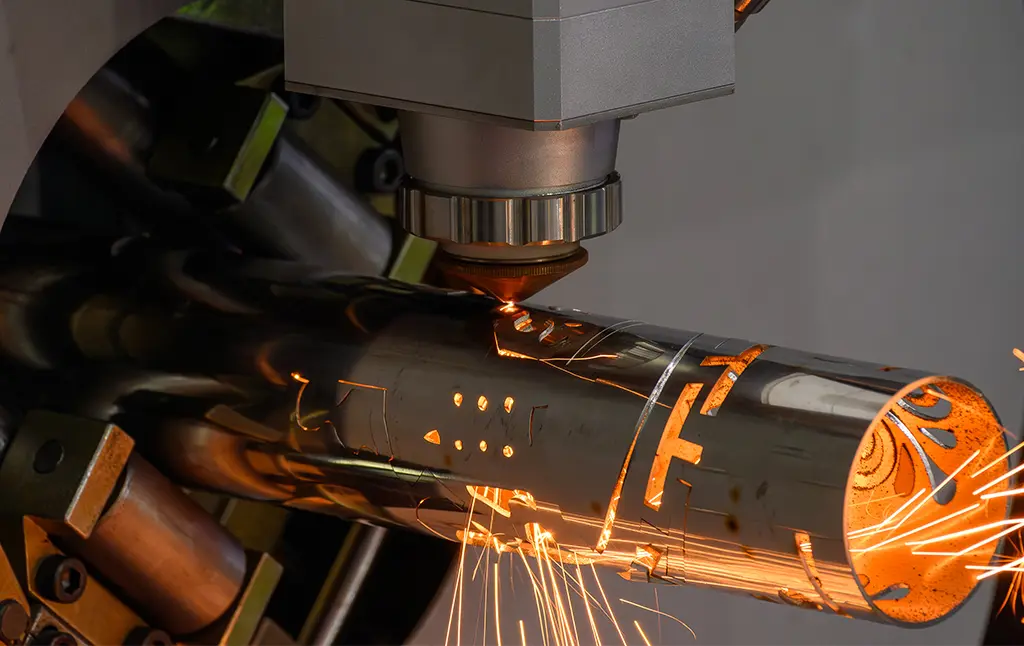

A modern CNC tube and profile laser cuts through these bottlenecks by replacing multiple slow, manual steps with a single, automated process. If you’re wondering how a tube laser can speed up your workflow, reduce downtime and increase production capacity, this guide walks through the key areas where the gains appear.

1. Faster Cutting Speeds Compared to Traditional Methods

One of the biggest advantages of a fibre tube laser is pure cutting speed.

Unlike mechanical saws or abrasive methods, a laser doesn’t need blade changes, tooth alignment or feed-rate adjustments. It cuts consistently from start to finish.

A tube laser can deliver:

• Higher linear cutting speeds on mild steel, stainless and aluminium

• Rapid transitions between features or part geometries

• Consistent cutting performance on round tube, square box section, RHS/SHS and open profiles

• No slowdown when cutting mitres, slots, holes or complex joints

For many workshops, increasing cutting speed alone creates an immediate boost in throughput and helps eliminate common bottlenecks in tube and section processing.

2. One Machine Replaces Multiple Processes

Tube lasers don’t just cut quickly, they remove entire stages of fabrication.

Tasks that usually require separate tools become a single, automated workflow.

A tube laser can replace:

• Measuring and marking

• Cutting to length

• Drilling holes

• Slotting

• Notching

• Cutting mitres

• Cutting weld-prep bevels (on machines with 3D bevel capability)

• Deburring (in many cases, edge quality reduces or eliminates this step)

This consolidation reduces labour, eliminates manual measurement errors and significantly shortens overall job time. What once required several tools and several operators can now be completed in a single cutting cycle.

3. Accuracy That Reduces Rework and Improves Fit-Up

Speed isn’t everything. In many workshops, the true time drain is rework; parts that don’t fit, joints that need grinding or holes that aren’t aligned.

A tube laser delivers:

-

Consistent dimensional accuracy

-

Perfect rotational alignment for around-the-tube features

-

Tight-tolerance mitres and joint preparation

-

Clean edges that improve welding fit-up

-

Reliable repeatability for batch production

When parts fit the first time, welding and assembly both become faster, more predictable and more cost-effective.

4. Automation Reduces Manual Handling and Operator Dependency

Manual loading and repositioning of long tubes and sections is slow, labour-intensive and often requires two people. Tube lasers equipped with automation dramatically reduce this handling burden.

Automation options can include:

-

Automatic bundle or magazine loading

-

Automated unloading and part sorting

-

Support systems for long tubes and open profiles

-

Self-centring pneumatic chucks

-

Automatic weld-seam detection and orientation

This allows operators to manage more work with less physical effort, improving productivity and overall workflow efficiency.

5. Smarter Programming, Nesting and Workflow Integration

A significant part of speeding up production comes from the digital workflow around the machine, not just the cutting itself.

Tube-specific CAD/CAM and nesting software allows:

-

Fast import of CAD drawings

-

Automatic feature alignment around the tube circumference

-

Multi-part nesting to minimise waste and cutting time

-

Predictable cycle times for easier scheduling

-

Libraries for repeat jobs

-

Faster setup compared to manual or semi-manual processes

This makes planning jobs quicker and more reliable, especially for workshops running mixed or repeat batches. Examples include Lantek Flex3D Tubes and SigmaTUBE SW (SigmaNest).

6. Consistency Across Shifts, Operators and Job Types

Human-led processes naturally vary from one operator to another, or from morning to evening. A tube laser produces the same results every cycle, regardless of material type, shift patterns or operator experience.

This reliability means:

-

Predictable timing

-

Fewer mistakes

-

Smoother workflow

-

Easier training

-

Higher-quality output across every shift

Consistency is often the hidden multiplier that allows a workshop to take on more work without needing extra staff.

7. Faster Lead Times and Higher Overall Output

When you combine all the advantages; faster cutting speeds, fewer manual processes, reduced handling, improved accuracy, automated workflow and predictable nesting, you arrive at the real impact:

Shorter lead times, more jobs per week, lower cost per part, and a significant increase in overall productivity.

This is why many fabrication businesses transition to tube laser cutting as a way to eliminate bottlenecks and future-proof their production capacity.

Thinking About Whether a Tube Laser Could Speed Up Your Production?

If you’re reviewing your workflow or exploring whether a tube and profile laser could make a measurable difference to your output, our team can help. We can look at the types of materials and profiles you process, understand your current bottlenecks and provide guidance on the improvements a modern tube laser could bring to your workshop.

Published 4th December 2025