Flexible machinery combinations for fabricators producing both tubular components and flat sheet-metal parts.

Many fabrication workshops no longer specialise exclusively in either tube or sheet-metal work; instead, they produce a mixture of brackets, plates, frames, tubular structures, covers, and architectural or structural components. Managing both workflows efficiently requires machinery that can adapt to frequent changeovers, varying materials, and diverse part types.

This page explores the challenges of hybrid tube/sheet workflows and the machinery combinations that support accurate, reliable, and cost-efficient production.

Challenges in Tube & Sheet Hybrid Production

Fabricators producing both flat and tubular components typically face:

-

Regular switching between tube cutting and sheet cutting

-

Maintaining accuracy across both profile-based and flat components

-

Limited space for multiple dedicated machines

-

Managing varied materials such as stainless, aluminium and mild steel

-

Reducing handling time between different production stages

-

Keeping changeovers quick enough for small and medium batch production

-

Minimising rework and reducing finishing time

-

Integrating tube, flat and formed components into one workflow

Hybrid production demands machines that deliver versatility without compromising performance.

Profiles & Materials in Hybrid Fabrication

Workshops commonly work with:

-

round, square and rectangular tube

-

box section and hollow structural section (RHS/SHS)

-

flat sheet and plate

-

angle, channel and flat bar

-

stainless steel, mild steel and aluminium

-

components requiring both bending and precision joint cut-outs

-

mixed-batch production of structural and architectural parts

This range of materials and shapes calls for machinery that supports both precision sheet processing and feature-rich tube cutting.

How Modern Machinery Supports Hybrid Tube & Sheet Workflows

Flatbed Fibre Lasers

Flatbed lasers remain essential for cutting:

-

brackets

-

base plates

-

panels and covers

-

gussets and stiffeners

-

decorative or architectural sheet components

Their speed and nesting efficiency make them ideal for high-volume sheet work within a hybrid environment.

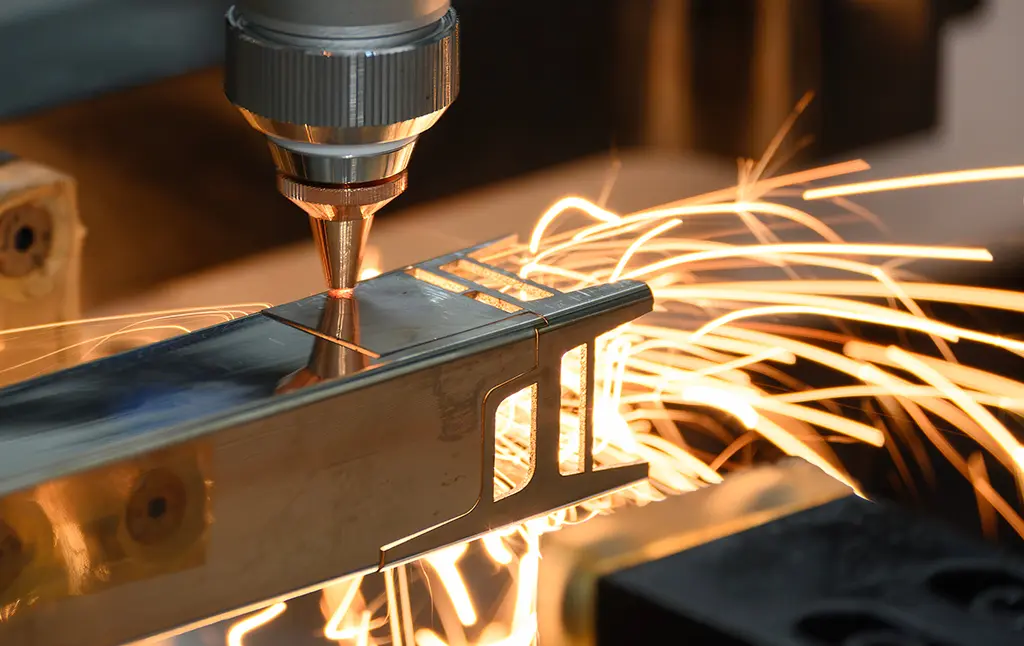

Tube & Section Lasers

Tube lasers support hybrid workflows by delivering:

-

precise mitres and notches

-

clean, consistent cuts on tube and box section

-

slots, holes and features cut in a single operation

-

reduced preparation and finishing time

-

accurate joints for weld-up with flat components

They dramatically improve consistency in assemblies that include mixed materials.

Combination Sheet & Tube Lasers

Combination lasers are designed specifically for hybrid workshops, offering:

-

both flat-sheet cutting and tube/section cutting in one footprint

-

reduced machine investment vs owning two separate systems

-

quick switching between sheet and tube operations

-

clean, accurate edges on all materials

-

excellent for small-to-medium fabrication shops

These machines minimise material handling and maximise efficiency across diverse workloads.

Press Brakes

Hybrid fabrication frequently requires forming:

-

brackets

-

panel components

-

folded structural parts

-

custom shapes

-

welded assemblies including tubular frames and sheet elements

CNC press brakes deliver accurate, repeatable bends across varied thicknesses and part types.

Guillotines

Hydraulic guillotines support:

-

straight cutting of sheet and plate

-

preparing blanks for bending or assembly

-

rapid trimming and resizing

-

clean, distortion-free shearing

A strong complement to flatbed or combination lasers.

H-Frame Presses, Horizontal Bending Machines and Box & Pan Folders

These machines support flexible hybrid environments by enabling:

-

simple forming operations

-

straightening and pressing tasks

-

bending of brackets and flat bar

-

low-volume or prototype work

-

quick folded components

They are practical, low-cost systems for varied general-purpose bending operations.

Steelworkers

Steelworkers enhance hybrid fabrication by allowing:

-

punching of holes and slots

-

shearing of bar, angle and plate

-

cropping and notching

-

quick preparation of structural components

Ideal for workflows involving both sheet and section materials.

Bandsaws

Bandsaws provide versatile preparation cutting for tube and section:

-

simple straight cuts

-

material preparation for tube laser or fabrication

-

accurate cutting of thicker profiles not suited to laser processing

They remain cost-effective and reliable for day-to-day production.

Laser Welding

Laser welding is increasingly used in hybrid environments for:

-

joining tube to flat components

-

producing low-distortion welds

-

visible architectural seams

-

stainless steel and aluminium work

-

small-batch or precision assemblies

Its accuracy and low heat input improve finish quality and reduce rework.

Customer Case Studies

Hear from some of our customers about how our machinery has helped them.

Recommended Machinery for Hybrid Tube & Sheet Workflows

Below are the machines best suited to this industry, grouped by type for easy navigation.

Example Components in Hybrid Fabrication

-

tubular frames with sheet-metal panels

-

brackets and mounting plates

-

structural and architectural assemblies

-

guards, covers and protective housings

-

rolled sheet components fitted to tube frames

-

fixtures, supports and custom assemblies

-

mixed-material welded structures

These components highlight how tube and sheet workflows naturally overlap.

Typical Hybrid Production Workflow

-

Material Preparation – bandsaw cutting, sheet trimming

-

Laser Cutting – tube, section, and flat sheet components

-

Forming – press brake bending, rolling, or folding

-

Drilling & Secondary Ops – holes, countersinks, tapping

-

Finishing – deburring, cleaning, weld prep

-

Welding & Assembly – tube-to-sheet assemblies, structural frames

-

Final Processing – adjustments, polishing or finishing

This workflow supports both one-off tasks and consistent batch production.

Why Choose Selmach for Tube & Sheet Hybrid Machinery?

-

Machinery tailored for multi-capability workshops

-

Solutions that combine flexibility, accuracy and throughput

-

UK-wide installation, training and aftercare

-

Decades of experience supporting mixed-material fabricators

-

Guidance based on your components, drawings and production goals

-

Systems designed for efficient switching between tube and sheet workflows

Speak to a Specialist

Tell us what components you produce, and we’ll recommend the most efficient machinery for your space, materials and production volume.

![Roller Track - 620mm Beam [Web] Roller Track - 620mm wide with a Beam on it](https://selmach.com/wp-content/smush-webp/2015/01/Roller-Track-620mm-Beam-Web.jpg.webp)