High-capacity machinery for cutting, drilling, forming and processing structural profiles and heavy steel components.

Structural steelwork demands strength, accuracy and repeatability on a scale few other fabrication sectors require. Whether you are producing beams, frames, platforms, brackets or large structural assemblies, the right machinery is essential for maintaining precision, managing heavy materials efficiently and increasing production throughput.

Selmach supplies a comprehensive range of equipment designed specifically for structural steel fabricators — from CNC plasma and tube/section lasers through to bandsaws, drills, press brakes and material-handling solutions. This page outlines the key challenges in structural fabrication and the machinery best suited to overcoming them.

Challenges in Structural Steel Fabrication

Steel fabricators typically face:

-

Cutting large profiles accurately and consistently

-

Handling long beams, box section, channel and angle

-

Managing heavy-gauge materials without distortion

-

Drilling and tapping holes in thick plate or structural members

-

Maintaining repeatability across series production

-

Reducing manual handling and bottlenecks in workflow

-

Balancing bespoke structural elements with repeat production

-

Achieving square, clean cuts with minimal secondary work

Traditional manual cutting and drilling methods can slow production significantly, create inconsistency and increase rework.

Profiles & Materials Used in Structural Fabrication

Common materials include:

-

Universal beams (UB) and universal columns (UC)

-

RHS / SHS box section

-

CHS round tube

-

Angle and channel sections

-

Flat bar and heavy plate

-

Mild steel structural components

-

Thick-wall tube and box section

-

Bracing, gusset plates and connector elements

These materials demand machinery capable of handling heavy weights, large dimensions and thick cross-sections.

How Modern Machinery Improves Structural Steel Production

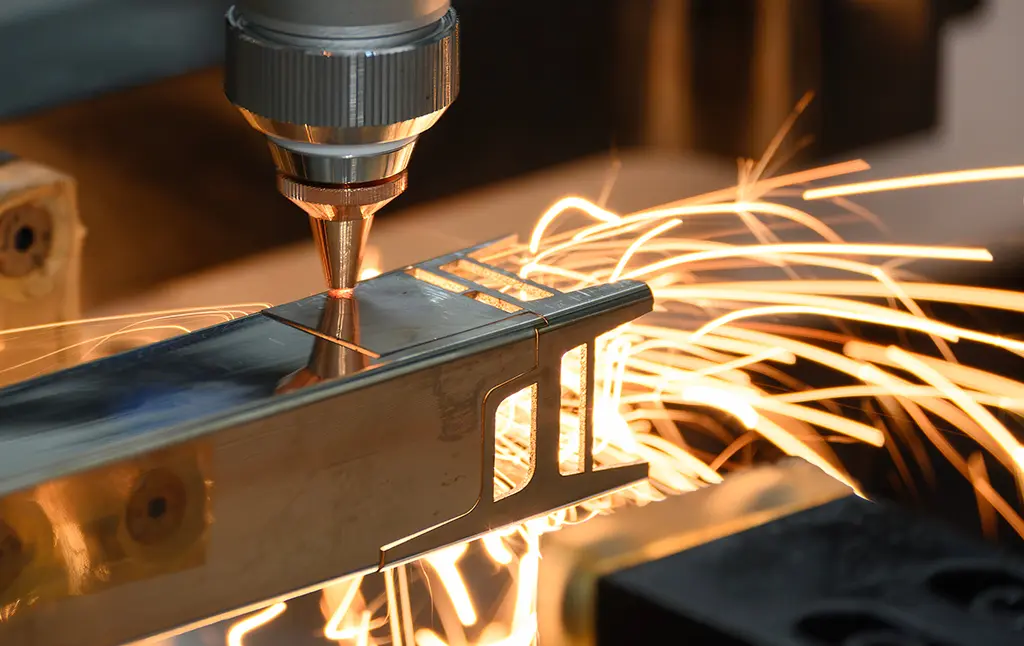

CNC Plasma Cutting

A core technology for structural fabrication, offering:

-

High cutting speeds on medium to thick plate

-

Cost-effective processing of large sheets

-

Ability to cut base plates, gussets, stiffeners, cleats and brackets

-

Accurate repeatability across batches

-

Bevel cutting options on some models

Plasma is ideal for heavy-duty structural parts where flat components form a significant portion of the workload.

Tube & Section Lasers

Laser cutting of box section, RHS/SHS and structural profiles provides:

-

Very accurate mitres and joints

-

Clean edges with minimal secondary work

-

Precision slotting, hole cutting and complex geometry

-

Reduced welding and assembly time

-

Faster production for architectural or lighter structural elements

While not essential for all steel fabricators, lasers provide major efficiencies where precision and aesthetic quality matter.

Press Brakes

Structural work frequently requires forming and bending of thick plates:

-

Stiffeners

-

Brackets

-

Angle plates

-

Custom structural details

-

Heavy folded components

Modern CNC press brakes provide control, accuracy and repeatability even on heavy materials

Bandsaws

A structural workshop essential:

-

Ideal for cutting beams, tubes, box section and heavy profiles

-

Clean, square cuts with excellent repeatability

-

Semi-auto and fully-auto feeding options for production environments

Bandsaws remain the go-to tool for bulk straight cutting and sawing production runs.

Drilling Machines – Pillar Drills & Radial Arm Drills

Pillar Drills

-

Perfect for repeat drilling operations on small-to-medium plates

-

Rigid and accurate

-

Suitable for thick structural steel components

Radial Arm Drills

-

Unmatched flexibility for drilling large plates or awkward structural members

-

Adjustable arm allows drilling across large areas without repositioning

-

Ideal for base plates, connection plates and heavy components

Radial drills are especially valuable for processing large, heavy items that cannot be easily moved.

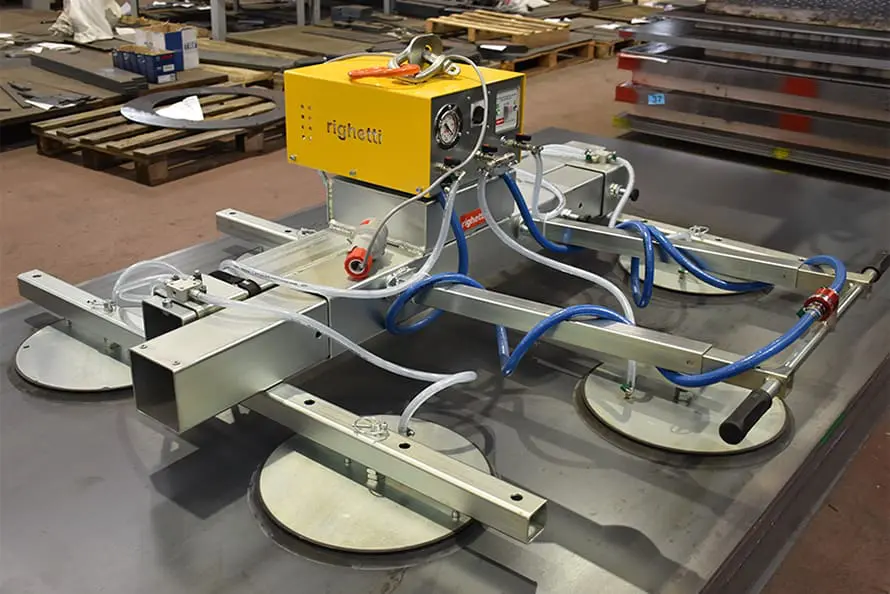

Material Handling & Preparation Equipment

Optional but impactful additions include:

-

Roller tracks for feeding beams and long profiles

-

Magnetic or pneumatic clamping systems

-

Deburring and finishing machines for plate and edge clean-up

-

Positioning tables for assembling large frames

These significantly improve workflow speed and operator safety.

Customer Case Studies

Hear from some of our customers about how our machinery has helped them.

Recommended Machinery for Structural Fabrication

Below are the machines best suited to this industry, grouped by type for easy navigation.

Example Components Produced in Structural Fabrication

-

Base plates

-

Stiffeners and gussets

-

Cleats and brackets

-

Structural frames

-

Cross members and braces

-

Box-section framework

-

Stair and platform components

-

Custom connection details

-

Heavy structural assemblies

Typical Workflow for Structural Steel Fabrication

A streamlined production line may include:

-

CNC Plasma Cutting

Cutting base plates, gussets, stiffeners and brackets. -

Bandsaw Cutting

Cutting box, angle, channel and beams to length. -

Tube or Section Laser (where applicable)

Precision cutting and advanced geometry for box section and structural profiles. -

Drilling (Pillar or Radial Arm)

Holes for bolted connections, brackets and structural joints (if no Plasma is available). -

Press Brake Forming

Formed plates, stiffeners and custom steel details. -

Finishing

Deburring, cleaning edges, weld prep. -

Assembly & Welding

Creating frames, structures and large assemblies.

Why Choose Selmach for Structural Steel Fabrication Machinery?

-

Wide range of machinery suited to heavy materials and large profiles

-

Decades of experience supporting steel fabricators

-

UK-wide installation, training and aftercare

-

Solutions tailored to your space, materials and production volume

-

Access to technical specialists who can help plan workflows and recommend the right equipment

-

Reliable machinery designed for long-term industrial use

Speak to a Specialist

Tell us what components you produce, and we’ll recommend the most efficient machinery for your space, materials and production volume.

![Roller Track - 620mm Beam [Web] Roller Track - 620mm wide with a Beam on it](https://selmach.com/wp-content/smush-webp/2015/01/Roller-Track-620mm-Beam-Web.jpg.webp)

![Meyer SR50VAE Pillar Drill [Web] Meyer SR50VAE pillar drill featuring a tall grey column, digital speed readout, black motor housing, adjustable circular table with crank handle, and a heavy-duty base for industrial use.](https://selmach.com/wp-content/smush-webp/2019/04/Meyer-SR50VAE-Pillar-Drill-Web.png.webp)