Flexible machinery for workshops handling a wide variety of materials, components and production volumes.

General fabrication environments rarely focus on a single product type. Instead, they handle a constantly shifting mix of tube, box section, angle, channel, sheet metal and plate work — often with varied batch sizes and tight turnaround requirements.

This page outlines the key challenges mixed-profile fabricators face and the machinery combinations that deliver the most efficient, flexible workflows.

Challenges in General Fabrication & Mixed Material Workflows

Fabrication shops operating across multiple sectors typically struggle with:

-

Switching between different materials and profile types quickly

-

Maintaining accuracy across small batches and one-off projects

-

Balancing bespoke work with repeat production

-

Cutting both tube/section and flat components on the same day

-

Handling awkward shapes and varying wall thicknesses

-

Managing limited floor space while needing multi-capability machinery

-

Reducing manual processing and rework

-

Ensuring consistent quality despite variable workloads

General fabrication demands versatility above all else — and your machinery must be able to adapt.

Profiles & Materials Commonly Found in Mixed Fabrication

Typical materials include:

-

Round, square and rectangular tube

-

Angle, channel, flat bar and open sections

-

Mild steel, stainless steel and aluminium

-

Structural box section and light-to-medium profiles

-

Sheet metal components

-

Plate elements for brackets, flanges, covers and supports

-

Custom decorative or functional shapes

These varied materials require equally varied machinery.

How Modern Machinery Supports General Fabrication

Flatbed Fibre Lasers

Flatbed lasers remain the workhorse for:

-

brackets, base plates and flanges

-

panels and covers

-

architectural or decorative elements

-

custom sheet components

They offer exceptional accuracy, fast production speeds and efficient sheet utilisation.

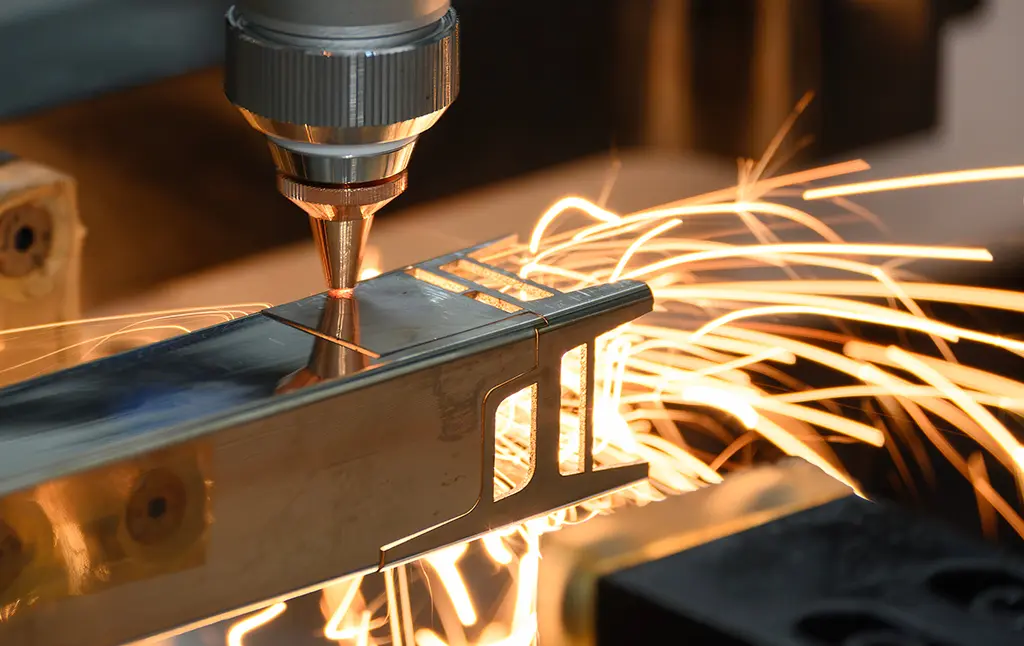

Tube & Section Lasers

Ideal for fabricators needing accurate cutting across numerous profile types. Benefits include:

-

Precision cutting of tube, box, angle and channel

-

Clean edges requiring minimal finishing

-

Ability to cut holes, slots and features in one operation

-

High repeatability, even on short-run or bespoke work

-

Automated loading options for increased throughput

Tube lasers bring consistency and speed to what is often a chaotic mix of components.

Combination Sheet & Tube Lasers

For workshops that frequently switch between tube and sheet work, combination machines are an excellent solution:

-

One machine for both flat and tubular components

-

Reduced footprint compared to two separate systems

-

Ideal for small-to-medium fabrication shops

-

Extremely cost-effective for mixed production environments

Press Brakes

General fabrication frequently requires forming:

-

brackets

-

mounting plates

-

frames

-

structural supports

-

small batch custom parts

CNC press brakes deliver consistent bending accuracy across any production volume.

Guillotines

Fabricators frequently use hydraulic guillotines for clean, accurate cutting of:

-

sheet metal and plate

-

blanks for bending or forming

-

straight edges prior to fabrication

-

material preparation for brackets and panels

-

rapid trimming or resizing tasks

Hydraulic guillotines deliver straight, consistent cuts with minimal distortion, making them ideal for workshops that need fast, reliable sheet preparation across a range of materials and thicknesses.

H-Frame Presses

Fabricators commonly use H-frame presses for:

-

pressing operations

-

straightening components

-

forming simple bends

-

assembling or extracting parts

-

maintenance and repair tasks

H-frame presses offer a versatile, cost-effective alternative to more complex forming machinery.

Horizontal Bending Machines

Horizontal bending presses support general fabrication tasks including:

-

small brackets and flat bar bends

-

angle correction and straightening

-

compact forming work

-

one-off or low-volume jobs

-

bending operations where vertical space is limited

- bespoke tooling for custom job work

They provide simple, efficient forming and are ideal for workshops needing flexible bending capability without a press brake.

Bandsaws

Still essential for:

-

straight cutting of box section, angle and bar

-

preparing materials before laser or secondary operations

-

handling heavier or larger materials cost-effectively

- semi-auto and automatic models can act as a silent employee churning out material for other processes.

Bandsaws offer reliability and low running costs.

Box & Pan Folders

Fabricators regularly use box and pan folders for producing:

-

trays and pans

-

small enclosures

-

covers and boxes

-

folded light-gauge components

-

prototype or short-run folded parts

These machines are ideal for quick, accurate folding where fast setup and ease of use are essential.

Drilling Machines – Pillar Drills

Drilling & Preparation Machines

Pillar drills and radial drills remain vital for:

-

drilling holes in plates and sections

-

tapping and countersinking

-

large or heavy components that require stable drilling positions

Finishing machines (deburring, linishing) support weld prep and reduce manual work.

Steelworkers

General fabrication shops rely on steelworkers for fast processing of:

-

angle, flat bar and box section

-

punching holes and slots

-

cropping and shearing materials

-

notching tasks

-

preparing components for assembly

Steelworkers provide a compact, multi-function solution that replaces several standalone machines, making them ideal for busy workshops handling varied cutting and punching requirements.

Laser Welding

General fabrication increasingly benefits from laser welding when producing:

-

thin-wall stainless and aluminium components

-

precise, low-distortion joints

-

visible architectural or decorative welds

-

sealed seams and continuous welds

-

small batch or repeat welded assemblies

Laser welding offers clean, narrow, accurate welds with minimal heat input, reduced distortion and significantly less post-weld finishing compared with traditional MIG or TIG processes.

Customer Case Studies

Hear from some of our customers about how our machinery has helped them.

Recommended Machinery for General Fabrication

Below are the machines best suited to this industry, grouped by type for easy navigation.

Example Components Produced in Mixed Fabrication Environments

-

brackets and mounting plates

-

tubular frames and supports

-

guards, covers and enclosures

-

box-section structures

-

architectural components

-

custom fixtures and assemblies

-

rolled or curved components

-

general welded or bolted assemblies

This variety reflects why flexible equipment is so important.

Typical Workflow for General Fabrication

A streamlined production flow may include:

-

Bandsaw or Tube Laser Cutting – preparing tube, section or box

-

Flatbed Laser or Guillotine – precision cutting of features from sheet materials

-

Sheet Forming (Press Brake, Box and Pan, H-Frame Press or Horizontal Bending Machine) – bending plates and structural parts

-

Drilling & Punching – holes, countersinks, tapping

- Rolling or Shaping – for curving sheets or sections ready for welding

-

Finishing – deburring, cleaning edges, weld prep

-

Assembly & Welding – assembling mixed material components

Workshops benefit most when each stage transitions cleanly to the next.

Why Choose Selmach for General Fabrication Machinery?

-

Machinery suited to varied workloads and material types

-

Solutions that combine flexibility, accuracy and reliability

-

UK-wide installation, training and long-term support

-

Decades of experience supporting multi-sector fabrication shops

-

Workflow-based advice based on your parts and production goals

-

Reliable equipment designed for busy, mixed-profile environments

Speak to a Specialist

Tell us what components you produce, and we’ll recommend the most efficient machinery for your space, materials and production volume.

![Roller Track - 620mm Beam [Web] Roller Track - 620mm wide with a Beam on it](https://selmach.com/wp-content/smush-webp/2015/01/Roller-Track-620mm-Beam-Web.jpg.webp)

![Meyer SR50VAE Pillar Drill [Web] Meyer SR50VAE pillar drill featuring a tall grey column, digital speed readout, black motor housing, adjustable circular table with crank handle, and a heavy-duty base for industrial use.](https://selmach.com/wp-content/smush-webp/2019/04/Meyer-SR50VAE-Pillar-Drill-Web.png.webp)