Machinery designed for precision, flexibility and clean finishes in lightweight frames, architectural furniture and bespoke metalwork.

Fabricators in the furniture and light manufacturing sectors work with a wide mix of tubular profiles, flat sheet components and decorative metal elements. The emphasis is often on aesthetic quality, repeatability and tight tolerances, especially for stainless steel, aluminium and lighter-gauge materials.

This page explores the unique requirements of furniture and light fabrication, along with the machinery combinations that best support accurate, efficient and reliable production.

Challenges in Furniture & Light Fabrication

Workshops in this sector frequently deal with:

-

achieving clean, visible joints on lightweight tube

-

maintaining high aesthetic standards on stainless and aluminium

-

producing small-batch or custom furniture designs efficiently

-

bending tube consistently without distortion or flattening

-

cutting profiles and materials with minimal burrs or finishing

-

handling a mixture of decorative and structural elements

-

processing thin-wall materials without damaging the finish

-

ensuring repeatability when manufacturing sets or matching assemblies

- avoiding contamination of stainless steel from mild steel

Quality, precision and repeatability are essential, especially for visible or decorative components.

Profiles & Materials Commonly Used in Furniture Manufacturing

Fabricators typically work with:

-

stainless steel and mild-steel tube

-

aluminium tube and extrusion

-

thin-wall profiles

-

decorative box section

-

flat sheet for panels and supports

-

round, oval and custom tube shapes

-

lightweight brackets and fittings

-

curved or rolled structural elements

Furniture projects often combine tube frames with sheet or plate components, requiring a versatile machinery lineup.

How Modern Machinery Supports Hybrid Tube & Sheet Workflows

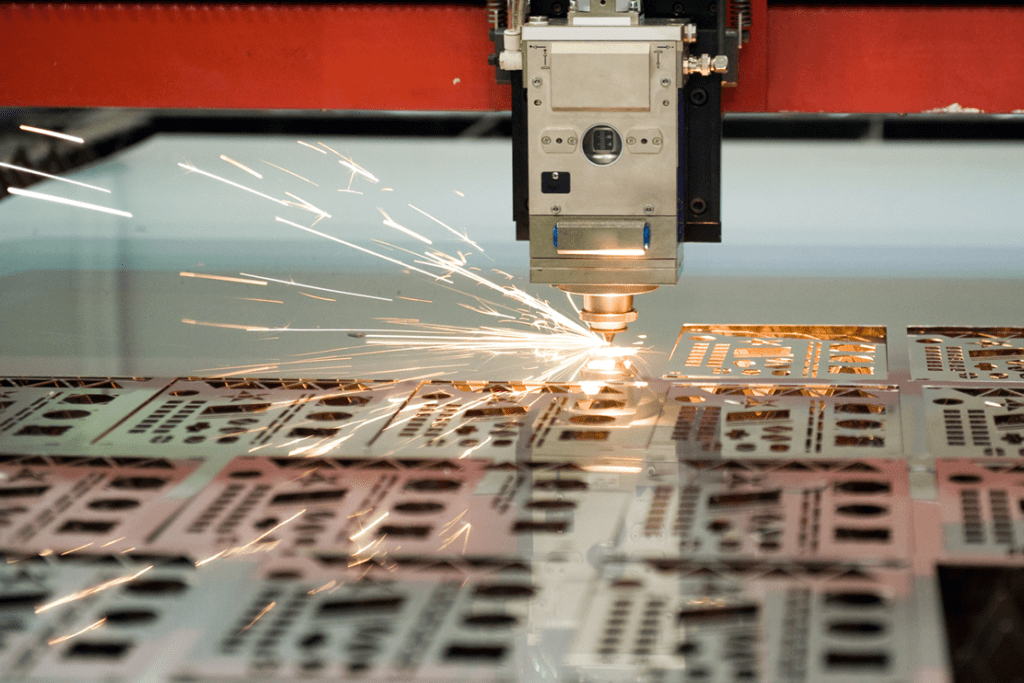

Flatbed Fibre Lasers

Flatbed lasers support:

-

brackets

-

panels and decorative plates

-

structural or architectural sheet components

-

precision-cut features

They deliver clean edges and consistent quality on thin material.

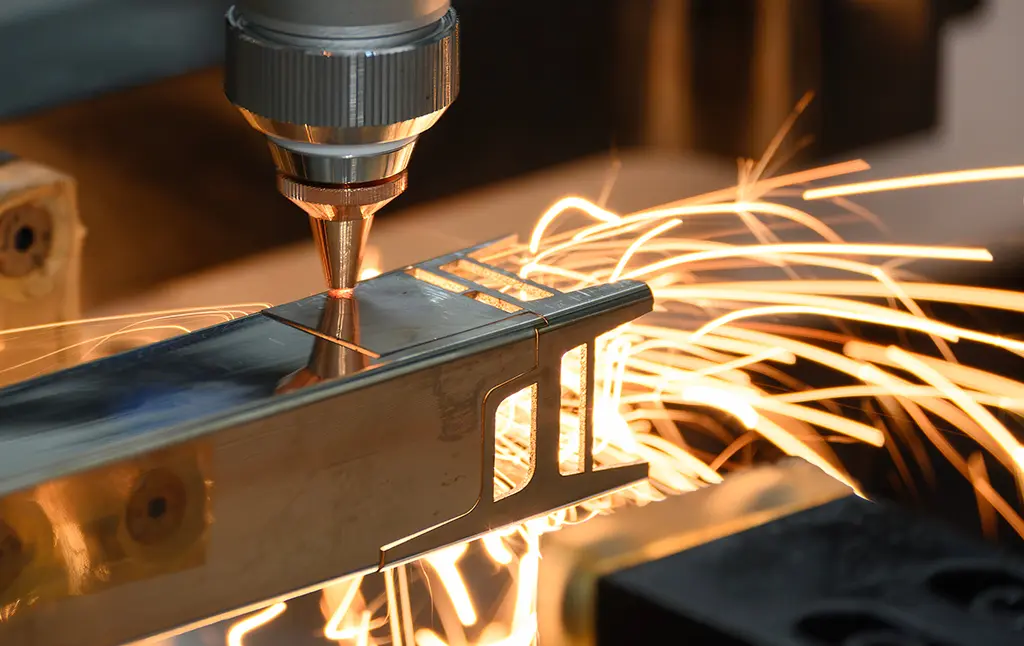

Tube & Section Lasers

Tube lasers are ideal for producing precise, clean joints for:

-

furniture frames

-

chair and table structures

-

tubular components requiring accurate mitres

-

slots, joint features and alignment tabs

They minimise finishing time and deliver excellent fit-up.

Press Brakes

Press brakes are essential for forming:

-

brackets

-

folded sheet components

-

lightweight frames

-

furniture support structures

CNC control ensures consistency across matching assemblies.

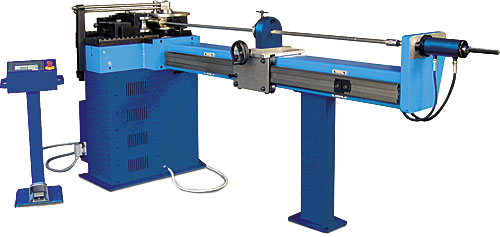

Tube Benders

A critical machine for this sector. Tube benders enable:

-

smooth, consistent bends in stainless and aluminium

-

chair and table frames

-

curved decorative features

-

repeatable production of matching components

-

low-distortion forming on thin-wall tube

They are indispensable for any workshop producing tubular furniture.

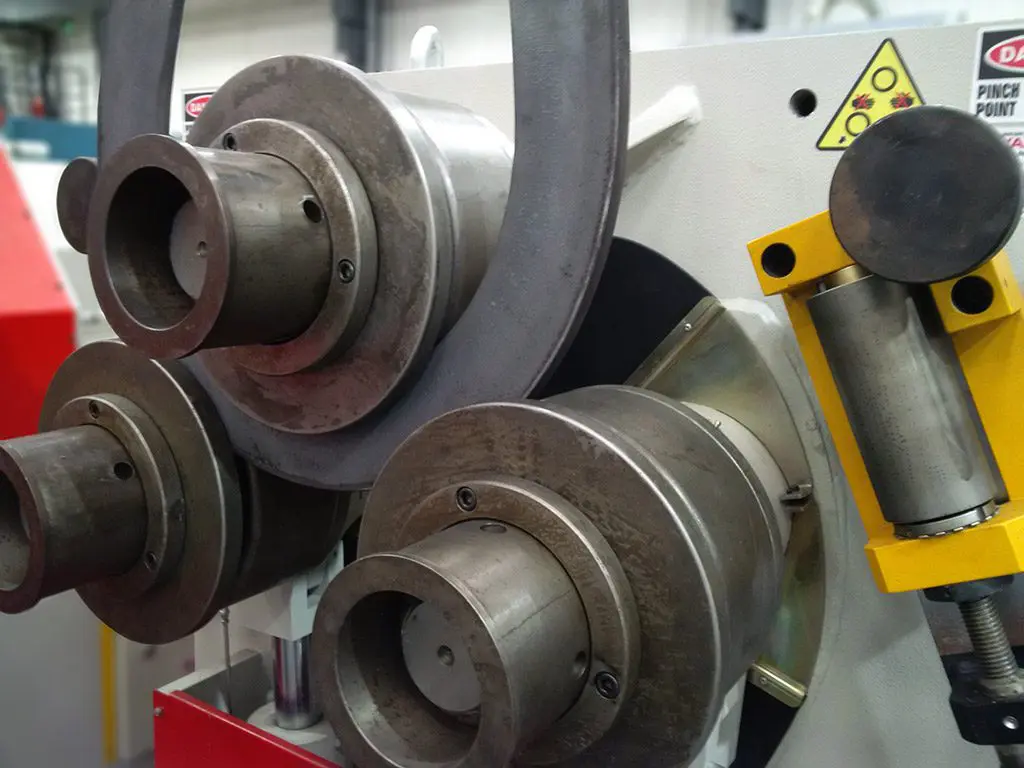

Section Rollers

Section rolls support the production of:

-

curved frames

-

circular furniture elements

-

arched structures

-

rolled tube and box section

-

decorative rings and arcs

They allow controlled, repeatable curves that elevate the quality of furniture designs.

Circular Saws & Aluminium Saws

Fast, clean cutting of tube and extrusion is critical in furniture manufacturing. Circular saws offer:

-

burr-free cuts

-

square, repeatable edges

-

fast cut cycles

-

suitability for stainless, mild steel and aluminium

Dedicated aluminium circular saws provide high-speed, chip-free cutting of extrusion and thin-wall profiles, ideal for lightweight frames and architectural aluminium components.

Bandsaws

Bandsaws provide versatile preparation cutting for tube and section:

-

simple straight cuts

-

material preparation for tube laser or fabrication

-

accurate cutting of thicker profiles not suited to laser processing

They remain cost-effective and reliable for day-to-day production.

Laser Welding

Laser welding is increasingly used for:

-

visible weld seams on stainless furniture

-

low-distortion joints

-

thin-wall tube assemblies

-

decorative or architectural components

-

precision welded frames

It produces extremely clean joints with minimal finishing.

Customer Case Studies

Hear from some of our customers about how our machinery has helped them.

Recommended Machinery for Furniture & Light Fabrication

Below are the machines best suited to this industry, grouped by type for easy navigation.

Example Components in Furniture & Light Fabrication

-

chair frames

-

table bases

-

decorative tubular structures

-

frames with curved or rolled elements

-

lightweight brackets

-

stainless and aluminium furniture

-

enclosures and small sheet components

-

architectural furniture elements

These components demonstrate the mix of tube, sheet and curved forms typical in this sector.

Typical Workflow for Furniture & Light Fabrication

-

Cutting – circular saw, aluminium saw, tube laser or flatbed laser

-

Bending & Forming – tube bender, press brake, section roll, sheet roll

-

Drilling & Preparation – pillar drills, tapping, finishing

-

Welding – MIG/TIG or laser welding for visible seams

-

Finishing – polishing, deburring, brushing

-

Assembly – final frame or furniture build

This workflow supports both custom pieces and repeat production runs.

Why Choose Selmach for Furniture & Light Fabrication Machinery?

-

Machinery suited to thin-wall tube, aluminium and decorative materials

-

Solutions focused on precision, surface quality and repeatability

-

UK-wide installation, training and maintenance support

-

Decades of experience with workshop layouts and light fabrication workflows

-

Guidance based on your components, drawings and production goals

-

A full range of cutting, bending, rolling and finishing machines for lightweight fabrication

Speak to a Specialist

Tell us about your components and materials — our team can recommend the ideal machinery for your furniture or light fabrication workflow.

![Roller Track - 620mm Beam [Web] Roller Track - 620mm wide with a Beam on it](https://selmach.com/wp-content/smush-webp/2015/01/Roller-Track-620mm-Beam-Web.jpg.webp)