Flexible, adaptable machinery for custom, one-off and short-run fabrication projects.

Bespoke and project-based fabrication is defined by variation — every job is different. From architectural features to custom frames, prototypes, artistic works, special-purpose structures and low-volume engineering projects, workshops in this sector need machinery that adapts easily to changing requirements.

This page outlines the challenges unique to bespoke fabrication and the machinery types that offer the versatility, accuracy and ease of setup needed to deliver high-quality results across diverse and unpredictable workloads.

Challenges in Bespoke & Project-Based Fabrication

Workshops producing custom or one-off components often face:

-

constant variation in part design, thickness and material

-

tight deadlines with limited scope for trial and error

-

small batch sizes where fast setup is essential

-

irregular or complex geometries

-

a mix of tube, section, sheet and plate

-

materials ranging from mild steel to stainless and aluminium

-

generating clean, accurate features for assemblies without jigs

-

managing unique or artistic shapes requiring specialist forming

Versatility and ease of switching between tasks are the core priorities in this environment.

Profiles & Materials Commonly Used in Bespoke Fabrication

Bespoke fabricators typically work with:

-

round, square and rectangular tube

-

angle, channel, flat bar and open sections

-

thin to medium-gauge sheet

-

plate for brackets and structural elements

-

stainless steel and aluminium for decorative or architectural work

-

rolled, curved or sculpted shapes

-

custom profiles defined per project

Machinery must be flexible enough to handle both simple and highly creative designs.

How Modern Machinery Supports Bespoke Fabrication

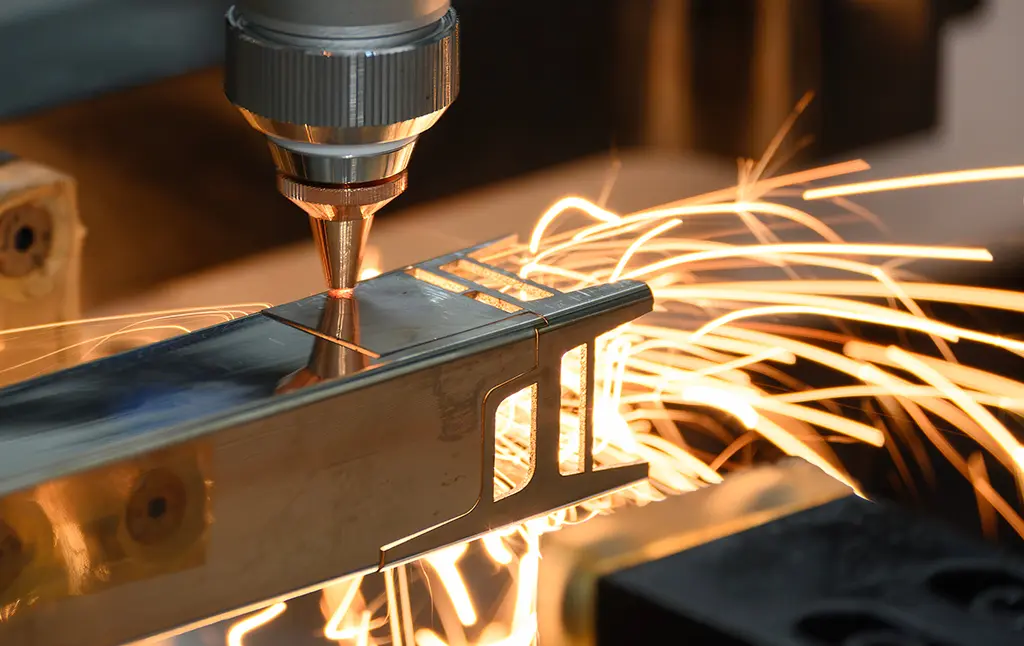

Flatbed Fibre Lasers

Flatbed lasers are perfect for custom part development, offering:

-

fast cutting of brackets, plates, panels and one-off details

-

clean edges suitable for visible architectural or decorative work

-

accurate reproduction of CAD-based designs

-

easy iteration for prototypes or adjustments

Their speed and precision make them ideal for highly varied project workloads.

Tube & Section Lasers

Tube lasers support bespoke work by enabling:

-

accurate mitres, joints and cut-outs on tubular structures

-

artistic or architectural tubular frames

-

custom slots and openings for creative assemblies

-

small batch runs of unique geometric tube components

They make precise tubular fabrication possible without extensive manual rework.

Press Brakes

General fabrication frequently requires forming:

-

brackets

-

mounting plates

-

frames

-

structural supports

-

small batch custom parts

CNC press brakes deliver consistent bending accuracy across any production volume.

Box & Pan Folders

Fabricators regularly use box and pan folders for producing:

-

trays and pans

-

small enclosures

-

covers and boxes

-

folded light-gauge components

-

prototype or short-run folded parts

These machines are ideal for quick, accurate folding where fast setup and ease of use are essential.

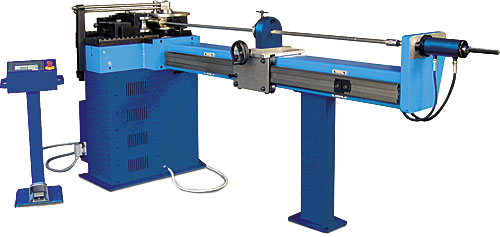

Tube Benders

Tube benders offer controlled forming for:

-

curved furniture pieces

-

artistic or architectural tube structures

-

bespoke frames

-

stainless or aluminium features requiring consistent bends

Essential for workshops producing curved or sculptural components.

Lathes

Lathes are used to manufacture:

-

custom spacers and bushings

-

decorative turned elements

-

precision components for unique assemblies

-

prototype and special-purpose parts

A flexible cornerstone machine for any project-based workshop.

Mills

Mills support:

-

machined features on bespoke parts

-

slots, pockets and precision surfaces

-

custom brackets and mounting features

-

small-run tooling or fixtures

Ideal for mixed fabrication and engineering-style work.

Pillar Drills

Pillar drills provide reliable drilling for:

-

holes in plates, brackets and custom components

-

prototype assemblies

-

one-off mounting features

-

countersinking and tapping

They are simple, accurate and fast to set up.

Bandsaws

Bandsaws support project-based production by offering:

-

flexible cutting of tube, bar, box and solid material

-

billet preparation for machining

-

straight, consistent cuts without complex setup

-

material preparation across varied project types

A dependable workhorse for unpredictable workloads.

Laser Welding

Laser welding is especially valuable for:

-

visible architectural or decorative components

-

stainless and aluminium bespoke work

-

thin-wall tube assemblies

-

clean, precise joints with minimal distortion

Its cosmetic quality makes it ideal for projects where appearance matters as much as strength.

Customer Case Studies

Hear from some of our customers about how our machinery has helped them.

Recommended Machinery for Bespoke Workshops

Below are the machines best suited to this industry, grouped by type for easy navigation.

Example Components Produced in Bespoke & Project-Based Fabrication

-

artistic or architectural metalwork

-

custom furniture pieces

-

prototype assemblies

-

curved tube components

-

decorative panels and formed sheet-metal elements

-

exhibition frames and one-off structural pieces

-

fixtures and mounting solutions

-

engineered components required in small quantities

This reflects the creative and varied nature of bespoke fabrication.

Typical Workflow in Bespoke & Project-Based Fabrication

-

Cutting – laser or saw depending on material

-

Forming – bending, rolling or shaping as required

-

Machining – lathes/mills for precision elements

-

Drilling – pillar drill for fixing points or assembly holes

-

Fitting & Assembly – test-fit or jig-less assembly

-

Welding – MIG/TIG or laser depending on appearance and strength

-

Finishing – smoothing, polishing or cleaning for final presentation

This flexible workflow suits highly varied, creative or technically demanding project work.

Why Choose Selmach for Bespoke Fabrication Machinery?

-

Solutions tailored to diverse, unpredictable workloads

-

Machinery designed for flexibility and fast setup

-

Support for both creative and technical fabrication projects

-

UK-wide training, installation and aftercare

-

Extensive experience with workshops producing custom and one-off items

-

Equipment chosen for accuracy, reliability and adaptability

Speak to a Specialist

Share your project types, materials and production challenges — we’ll help configure the ideal machinery for your bespoke workflow.

![Roller Track - 620mm Beam [Web] Roller Track - 620mm wide with a Beam on it](https://selmach.com/wp-content/smush-webp/2015/01/Roller-Track-620mm-Beam-Web.jpg.webp)

![Meyer SR50VAE Pillar Drill [Web] Meyer SR50VAE pillar drill featuring a tall grey column, digital speed readout, black motor housing, adjustable circular table with crank handle, and a heavy-duty base for industrial use.](https://selmach.com/wp-content/smush-webp/2019/04/Meyer-SR50VAE-Pillar-Drill-Web.png.webp)