Precision machinery for high-accuracy, repeatable parts across automotive, motorsport and engineering applications.

Automotive and engineering workshops demand exceptional precision, clean edges, and reliable repeatability. Whether producing chassis elements, brackets, flanges, bush housings, exhaust components or machined parts, high-performance machinery is essential for achieving the tolerances and finish quality these industries require.

This page outlines the core challenges faced by automotive and engineering manufacturers, and highlights the key machinery best suited to supporting accuracy, consistency and efficient production.

Challenges in Automotive & Engineering Fabrication

Workshops in this sector often contend with:

-

producing parts with strict dimensional tolerances

-

maintaining consistency across repeated batches

-

cutting both sheet and tubular components with minimal distortion

-

machining precision features for engineered assemblies

-

forming components accurately for jig-based assembly

-

welding thin-wall stainless or aluminium components cleanly

-

rapid prototyping alongside production runs

-

processing a wide variety of small, medium and structural parts

Accuracy, repeatability and surface finish are critical in all stages of production.

Materials & Profiles Commonly Used in Automotive and Engineering Work

These industries regularly use:

-

mild steel, stainless steel and aluminium

-

round and rectangular tube

-

thin-wall tubing for lightweight structures

-

precision plate and sheet components

-

machined billets and blocks

-

laser-cut brackets, mounts and tabs

-

components requiring tight-fit assemblies

This diverse material mix requires machinery capable of precision cutting, bending, machining and joining.

How Modern Machinery Supports Automotive & Engineering Production

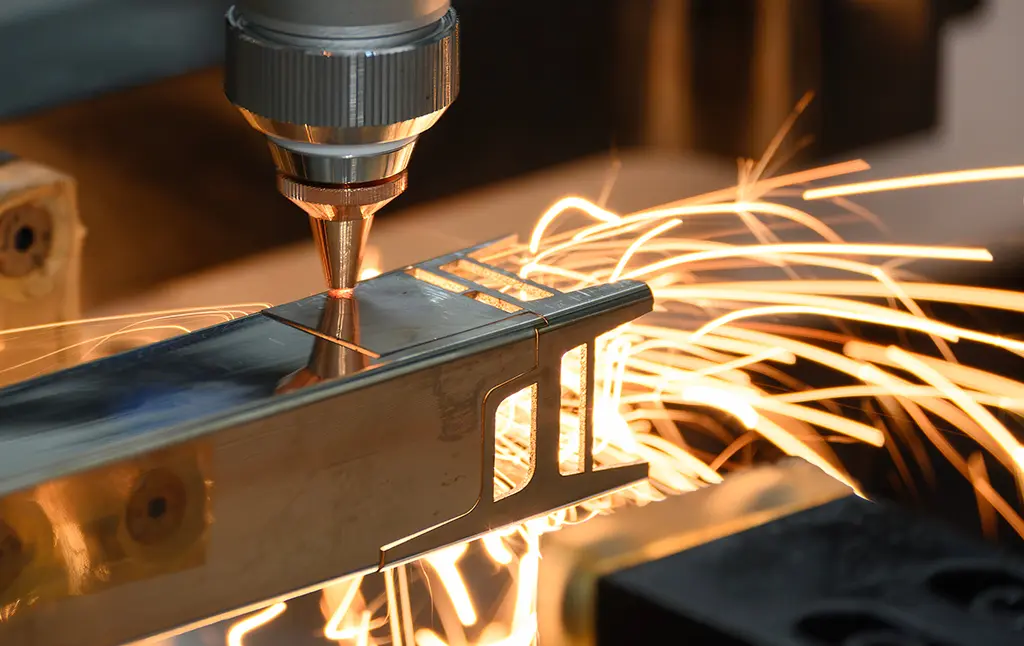

Flatbed Fibre Lasers

Flatbed lasers provide high-accuracy cutting for:

-

brackets

-

mounting plates

-

gussets and tabs

-

prototype components

-

thin to medium-gauge panels

-

lightweight engineered parts

Their tight tolerances and clean edges make them ideal for assembly-critical automotive and engineered components.

Tube & Section Lasers

Tube lasers excel in producing:

-

chassis tubes

-

roll-cage components

-

precision mitres and notches

-

tubes with cut-outs for jigs and fixtures

-

stainless or aluminium components requiring clean fit-up

They greatly reduce manual preparation and ensure accurate, repeatable joint geometry.

Press Brakes

Press brakes support the forming of:

-

brackets

-

reinforcement plates

-

folded housings

-

structural supports

-

engineered sheet-metal components

CNC control delivers consistent bend angles and repeat accuracy across any batch size.

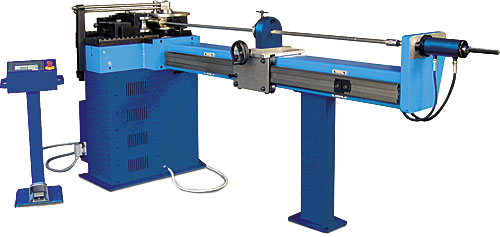

Tube Benders

Tube benders are essential for the controlled forming of:

-

chassis tubes

-

roll-cage elements

-

frames

-

aluminium or stainless tube components

-

curved structural parts used in motorsport or engineering

They provide consistent, low-distortion bending for both prototypes and batch production.

Box and Pan Folders

Box and pan folders are valuable for producing:

-

electrical enclosures

-

small boxes

-

light-gauge housings

-

folded covers and panels

-

prototypes requiring fast turnaround

They allow quick setup and precise folding for small engineered components.

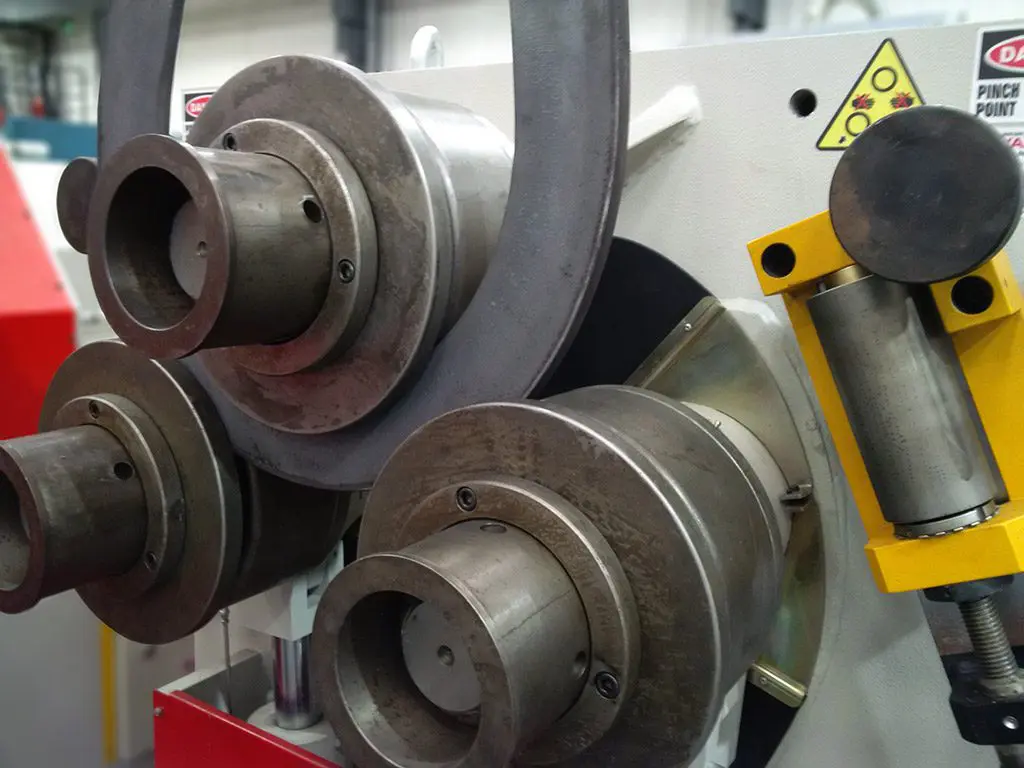

Section Rollers

Section rolls support the production of:

-

curved frames

-

circular furniture elements

-

arched structures

-

rolled tube and box section

-

decorative rings and arcs

They allow controlled, repeatable curves that elevate the quality of furniture designs.

Bandsaws

Bandsaws support automotive and engineering production by:

-

cutting tube, bar and box section to length

-

preparing stock ahead of machining or fabrication

-

cutting down solid billets ready for machining into components

-

offering straight, accurate cuts with reliability

Billet cutting is particularly important for motorsport and custom-engineered parts that are cut out on lathes and mills.

Lathes

Lathes support the manufacture of precision-turned components such as:

-

spacers

-

bushings

-

shafts and pins

-

threaded parts

-

machined tube ends

-

billet components requiring concentric accuracy

A core machine in any engineering environment.

Turret Mills

Mills are used for producing:

-

accurately machined features

-

slots, pockets and flat surfaces

-

precision mounting points

-

custom fixtures and tooling

-

components cut from billet or plate

They allow highly controlled, repeatable remove-material machining.

Pillar Drills

Pillar drills provide fast, accurate drilling for:

-

brackets

-

mounting plates

-

larger fabricated components

-

precise hole locations

-

tapping and countersinking

A dependable machine for repeat drilling operations.

Laser Welding

Laser welding is increasingly used in automotive applications for:

-

stainless exhaust systems

-

thin-wall tube joints

-

highly cosmetic visible welds

-

clean, narrow seams with minimal heat input

-

precision welding on lightweight structures

It produces exceptionally clean welds, reduces working time and HAZ and eliminates much of the post-process finishing required with TIG welding.

Customer Case Studies

Hear from some of our customers about how our machinery has helped them.

Recommended Machinery for Automotive & Engineering Workshops

Below are the machines best suited to this industry, grouped by type for easy navigation.

Example Components in Automotive & Engineering Production

-

chassis and roll-cage tubes

-

brackets, gussets and tabs

-

motorsport components

-

billet-machined parts

-

machined bushings and spacers

-

exhaust systems and stainless assemblies

-

prototype mounts and fixtures

-

lightweight sheet-metal assemblies

These reflect the precision-driven nature of automotive and engineering work.

Typical Workflow in Engineering & Automotive Fabrication

-

Cutting — flatbed laser, tube laser or billet cutting on bandsaw

-

Forming — press brake, tube bending or folding

-

Machining — lathe or mill for precision features

-

Drilling — pillar drill for holes, tapping or countersinking

-

Finishing — deburring, polishing, cleaning

-

Welding — laser welding for exhausts or high-quality joints

-

Assembly & Fit-Up — precision jig-based assembly

-

Prototype or Production Run — scalable from one-off to batch work

This workflow supports both engineering prototypes and repeatable automotive series production.

Why Choose Selmach for Automotive & Engineering Machinery?

-

Machinery designed for high accuracy and repeatability

-

Equipment suitable for both prototype development and batch manufacture

-

Solutions covering cutting, machining, forming and welding

-

Expertise in mixed-process engineering environments

-

UK-wide support, installation and training

-

Guidance based on component drawings, tolerances and production volumes

Speak to a Specialist

Tell us about your components and materials — our team can recommend the ideal machinery for your furniture or light fabrication workflow.

![Roller Track - 620mm Beam [Web] Roller Track - 620mm wide with a Beam on it](https://selmach.com/wp-content/smush-webp/2015/01/Roller-Track-620mm-Beam-Web.jpg.webp)

![Meyer SR50VAE Pillar Drill [Web] Meyer SR50VAE pillar drill featuring a tall grey column, digital speed readout, black motor housing, adjustable circular table with crank handle, and a heavy-duty base for industrial use.](https://selmach.com/wp-content/smush-webp/2019/04/Meyer-SR50VAE-Pillar-Drill-Web.png.webp)