Precision cutting, forming and finishing systems for handrails, balustrades, frames and decorative structures.

Architectural metalwork demands clean lines, accurate joints and a consistently high-quality finish — often in stainless steel or aluminium where every imperfection is visible. Whether you are producing handrails, balustrades, frames, gates or bespoke decorative components, the right machinery can make the difference between slow, labour-intensive processes and efficient, repeatable production.

Selmach supplies a complete range of machinery for architectural metalwork, from tube and section lasers through to press brakes, section rollers, and finishing equipment. This page explores how these technologies help solve industry challenges, and which models best suit different workshop environments.

Challenges in Architectural Metalwork Fabrication

Architectural fabricators commonly face:

-

Achieving precise mitres and joint fit-up without extensive grinding

-

Maintaining clean, consistent edges on stainless and aluminium

-

Handling awkward tube and section profiles with accuracy

-

Producing repeatable bends, brackets and formed components

-

Reducing distortion during cutting

-

Managing small-batch or bespoke workflows efficiently

-

Achieving decorative finishes with minimal secondary work

Traditional methods — saws, abrasive cutting, drilling, manual forming — struggle to deliver the precision and consistency needed in modern architectural metalwork.

Profiles & Materials Used in Architectural Fabrication

Architectural metalwork typically includes:

-

Round tube (stainless, mild steel, aluminium)

-

Square and rectangular box section (RHS/SHS)

-

Flat-sided or oval tube

-

Angle and channel sections

-

Flat bar and architectural plate components

-

Decorative or custom profiles

-

Thin- to medium-wall materials needing clean, accurate edges

This diversity of materials and geometries requires flexible machinery that can switch between tasks quickly and maintain consistent quality.

How Modern Machinery Improves Architectural Metalwork Production

Sheet Lasers

Flatbed fibre lasers are used for:

-

brackets

-

base plates

-

decorative components

-

façade elements

-

flat parts for railing systems

They provide tight tolerances, clean edges and the ability to nest complex shapes efficiently.

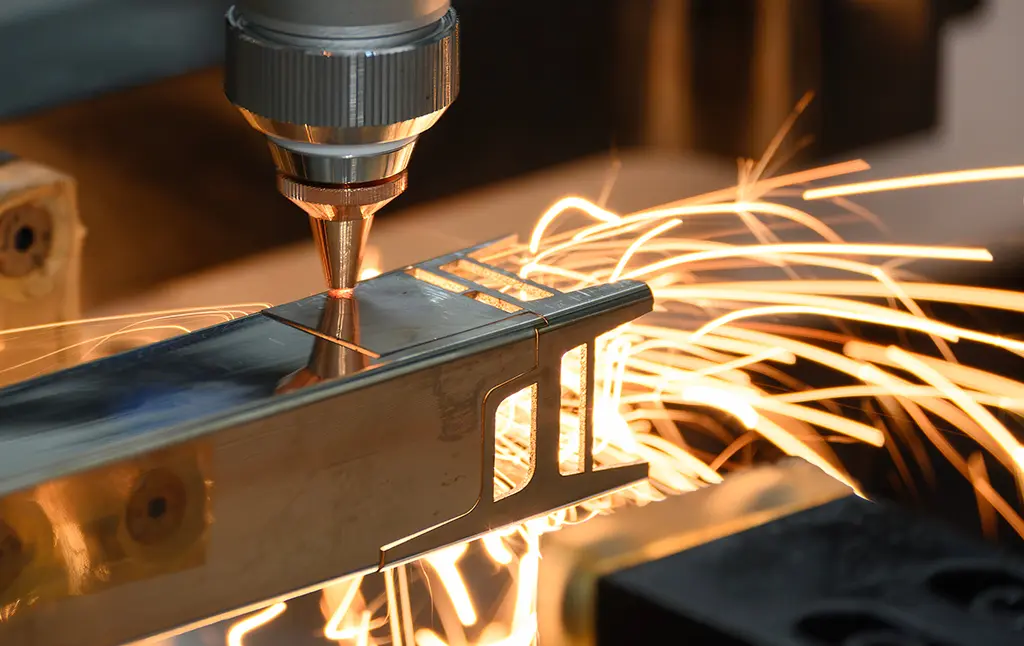

Tube & Section Lasers

Tube lasers are ideal for architectural work due to their:

-

extremely accurate mitres and joint geometry

-

clean, consistent cuts requiring minimal finishing

-

repeatable results on stainless and aluminium

-

ability to cut holes, slots and notches in one operation

-

smooth integration with press brakes and rollers downstream

-

automation options that reduce manual handling

This significantly accelerates production compared with saws, grinders or plasma cutting.

Press Brakes

Press brakes are fundamental for forming:

-

brackets

-

stiffeners

-

support plates

-

architectural frames

-

bespoke decorative structures

Modern CNC controls ensure consistent results across batches.

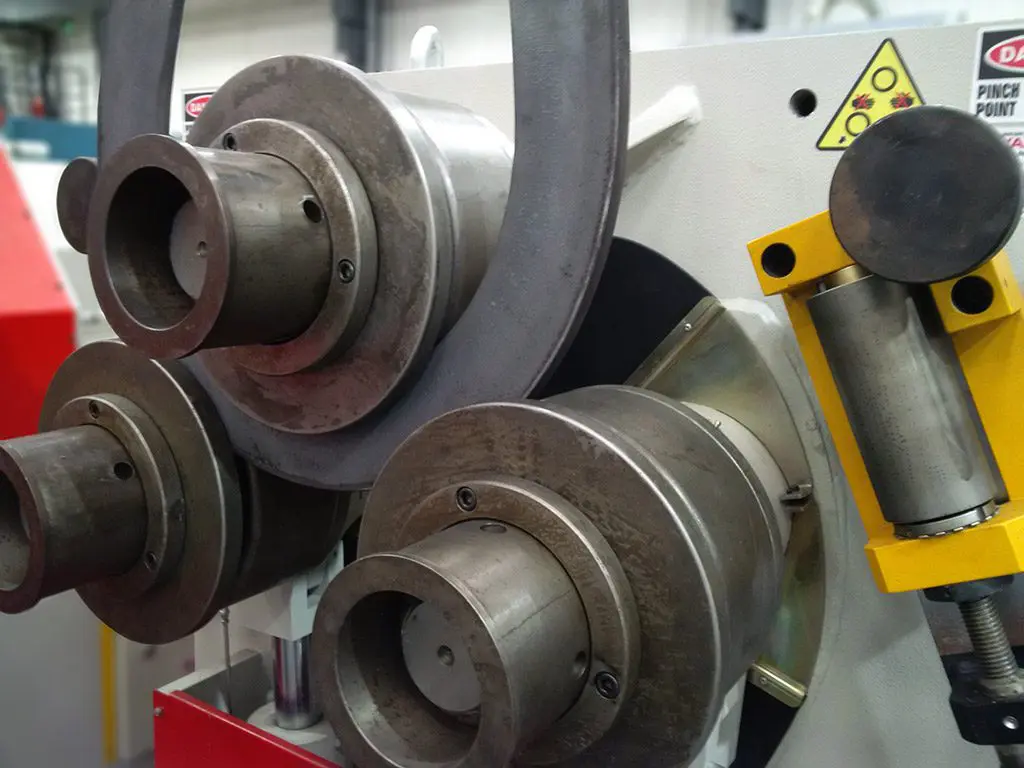

Section Rollers

Section rollers support the production of:

-

curved handrails

-

circular balustrades

-

decorative curves

-

curved box section frames

They deliver predictable rolling results without distortion.

Finishing & Preparation Equipment

Finishing machines help:

-

polish stainless components

-

deburr laser-cut edges

-

prepare surfaces for architectural-quality presentation

This reduces manual polishing time and elevates final quality.

Customer Case Studies

Hear from some of our customers about how our machinery has helped them.

Recommended Machinery for Architectural Metalwork

Below are the machines best suited to this industry, grouped by type for easy navigation.

Example Components Produced in Architectural Metalwork

-

Handrail tubes and bends

-

Balustrade uprights

-

Decorative frames

-

Staircase components

-

Brackets and connectors

-

Curved handrail sections

-

Furniture frames

-

Structural support elements

-

Custom architectural features

Typical Workflow for Architectural Metalwork Fabrication

A complete workflow might look like:

-

Tube Laser Cutting – mitres, notches, slots, joint details

-

Sheet Laser Cutting – brackets, plates, decorative parts

-

Press Brake Forming – bending plates and frames

-

Section Rolling – creating curved railings and architectural forms

-

Finishing & Polishing – preparing stainless/aluminium surfaces

-

Assembly & Welding – improved fit-up speeds up final fabrication

Why Choose Selmach for Architectural Fabrication Machinery?

-

Full machinery ecosystem for tube, section and sheet workflows

-

UK-wide installation, training and aftercare

-

Experience supporting architectural metalwork fabricators

-

Advice based on real layouts, materials and parts

-

Long-term service support and stocked spares

-

Guidance on selecting the right machine combination

Speak to a Specialist

Tell us what components you produce, and we’ll recommend the most efficient machinery for your space, materials and production volume.