Heavy-duty machinery for producing durable frames, chassis components and wear parts for agricultural equipment and trailers.

Agricultural and trailer fabrication demands robust, repeatable processes for working with thick materials, large sections and structural assemblies. Whether you’re manufacturing trailer chassis, drawbars, agricultural attachments, Hardox wear parts or heavy brackets, you need machinery that can handle big sections, high loads and long production runs.

This page outlines the key challenges in agricultural and trailer manufacturing and the machinery best suited to improving productivity, accuracy and long-term reliability.

Challenges in Agricultural & Trailer Fabrication

Workshops in this sector typically face:

-

cutting thick plate, Hardox and other high-strength steels

-

processing large RHS/SHS, beams, angle and channel

-

handling long chassis rails, drawbars and frames

-

producing repeatable structural components at volume

-

drilling heavy plates and large fabrications accurately

-

forming heavy-gauge components with consistent bending

-

rolling large sheets for tanks, trailers and agricultural equipment

-

maintaining throughput whilst ensuring strong, reliable joints

Robust, high-capacity machinery is essential to keep production efficient and safe.

Materials & Profiles Commonly

Used in Agricultural & Trailer Manufacturing

Fabricators regularly work with:

-

mild steel and heavy-gauge plate

-

high-strength and wear-resistant steels (e.g. Hardox)

-

RHS/SHS box section and CHS tube

-

angle, channel and I-beam sections

-

flat bar and structural strip

-

sheet metal for guards, covers and side panels

-

components needing both structural strength and good fit-up

Your machinery must cope with both precise fabrication and large-scale structural work.

How Modern Machinery Supports Agricultural & Trailer Manufacturing

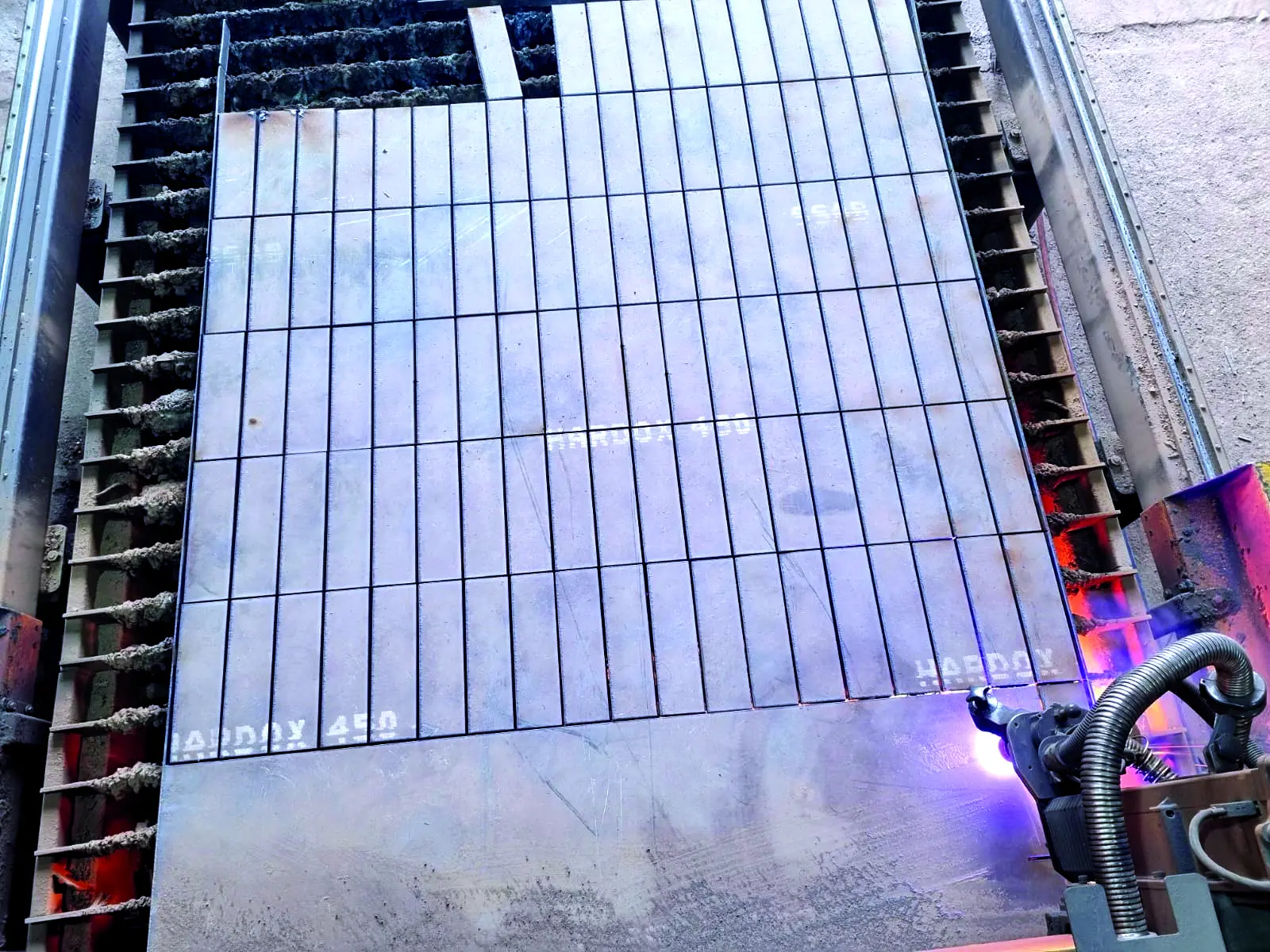

CNC Plasma Cutters

CNC plasma systems are a cornerstone of heavy fabrication, especially for:

-

thick plate cutting

-

Hardox and wear-plate components

-

digger bucket profiles and wear strips

-

heavy brackets and reinforcement plates

-

agricultural implement parts

They offer fast, cost-effective cutting of heavy and wear-resistant steels where high strength is essential.

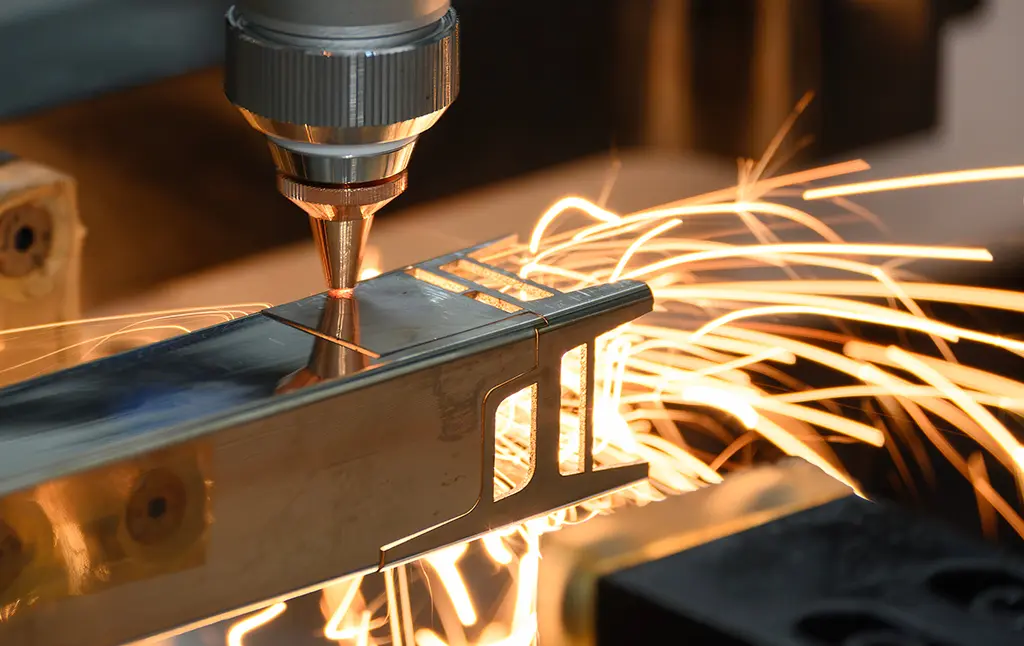

Flatbed Fibre Lasers

Flatbed lasers are ideal for:

-

brackets and mounting plates

-

gussets and stiffeners

-

hitch plates and coupling components

-

guards, covers and panel work

They deliver accurate, clean edges that improve weld fit-up and reduce rework.

Tube & Section Lasers

Tube and section lasers are ideal for cutting:

-

chassis rails and cross members

-

box-section frames

-

structural supports and linkages

-

precisely mitred drawbar components

-

cut-outs and slots in RHS/SHS and CHS

They deliver clean, accurate cuts on RHS, SHS, CHS, angle and channel, reducing manual prep and improving assembly speed.

Press Brakes

Press brakes, especially high tonnage models are used extensively to form:

-

structural brackets

-

hinge and mounting plates

-

folded sections for frames

-

reinforcement pieces

-

folded components for trailer bodies and agricultural attachments

CNC press brakes provide repeatable, accurate bending on heavy and medium plate.

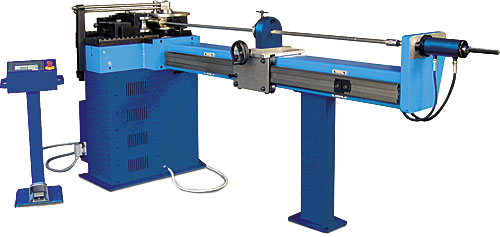

Tube Benders

Tube benders support the fabrication of:

-

curved drawbar and frame elements

-

protective hoops and guards

-

hydraulic and mechanical linkage tubes

-

custom tubular components for agricultural machines

They provide consistent, low-distortion bends across various tube sizes.

Sheet Rolls

Large capacity sheet rolls are crucial for:

-

rolling heavy plate into cylinders or cones

-

slurry tank sections

-

trailer sides and curved bodies

-

agricultural tankers and hoppers

-

structural rolled shells and heavy covers

They deliver controlled forming of large-diameter, thick material components.

Lathes

Lathes are used to produce:

-

bushings and spacers

-

pins and shafts

-

axle components

-

turned fittings for hinges and couplings

Turned parts are critical in pivot points, linkages and running gear.

Mills

Milling machines support:

-

machined faces and mounting surfaces

-

precision slots and pockets

-

custom brackets and fixtures

-

machined details on plates and blocks

They ensure accurate fit between fabricated and machined components.

Bandsaws

Bandsaws provide reliable cutting for:

-

beams, box section, angle and channel

-

solid bar and billets for machined components

-

preparing stock for welding or machining

-

cutting material to length efficiently

They are essential for handling heavy structural profiles and feedstock.

Pillar Drills

Pillar drills are ideal for:

-

drilling bracket holes

-

preparing mounting points

-

tapping and countersinking

-

repetitive drilling on plates and components

A dependable machine for repeat hole-making in heavy and medium sections.

Radial Arm Drills

Radial arm drills are especially valuable for:

-

drilling large or heavy plates that are difficult to move

-

drilling into large frames, beams or assemblies

-

accurately spacing holes across bigger components

-

working on awkward or oversized fabrications

The extended reach allows drilling operations across a broad area without constant repositioning.

Steelworkers

Steelworkers provide fast, versatile processing for:

-

punching accurate holes and slots in flat bar, angle and plate

-

shearing and cropping bar, box section and angle

-

notching plate and section materials

-

preparing components for welding or bolted assembly

They combine multiple fabrication functions into one compact, efficient machine, making them invaluable for workshops handling repetitive structural tasks and varied everyday fabrication work.

Customer Case Studies

Hear from some of our customers about how our machinery has helped them.

Recommended Machinery for Agricultural & Trailer Workshops

Below are the machines best suited to this industry, grouped by type for easy navigation.

Example Components in Agricultural & Trailer Fabrication

-

trailer chassis and cross members

-

drawbars and coupling plates

-

Hardox wear plates and bucket profiles

-

brackets, gussets and stiffeners

-

hinge plates and linkage components

-

tank and body sections rolled from plate

-

axle fittings, pins and machined parts

-

structural frames for agricultural machinery

These parts illustrate the combination of heavy structural work and precise component manufacture.

Typical Workflow in Agricultural & Trailer Manufacturing

-

Cutting – CNC plasma or flatbed laser for plate; tube/section laser or bandsaw for profiles

-

Forming – press brake for brackets and plates; big sheet rolls for tanks and bodies; tube benders for curved elements

-

Machining – lathes and mills for pins, bushings and precision features

-

Drilling – pillar drills for standard work; radial arm drills for large plates and frames

-

Finishing – deburring and cleaning edges for weld prep

-

Welding – structural welding of frames and bodies

-

Assembly – integrating chassis, bodies, drawbars and attachments

This workflow suits both serial production and one-off agricultural builds.

Why Choose Selmach for Agricultural & Trailer Fabrication Machinery?

-

Machinery designed for heavy-duty fabrication and structural production

-

Solutions for both high-strength plate work and precise components

-

Experience with workflows involving chassis building, attachments and wear parts

-

UK-wide installation, training and ongoing support

-

Guidance based on your components, material thicknesses and production targets

-

Equipment selected for durability and reliability in demanding environments

Speak to a Specialist

Tell us about the trailers, attachments or agricultural equipment you produce — we’ll recommend the machinery combination that best supports your workload and growth plans.

![Roller Track - 620mm Beam [Web] Roller Track - 620mm wide with a Beam on it](https://selmach.com/wp-content/smush-webp/2015/01/Roller-Track-620mm-Beam-Web.jpg.webp)

![Meyer SR50VAE Pillar Drill [Web] Meyer SR50VAE pillar drill featuring a tall grey column, digital speed readout, black motor housing, adjustable circular table with crank handle, and a heavy-duty base for industrial use.](https://selmach.com/wp-content/smush-webp/2019/04/Meyer-SR50VAE-Pillar-Drill-Web.png.webp)